Method for preparing diesel vehicle exhaust gas purification molecular sieve

A tail gas purification and molecular sieve technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of narrow temperature range, poor low-temperature activity of catalysts, high price, etc., achieve good hydrothermal stability, and improve low-temperature denitrification Performance, the effect of improving high temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

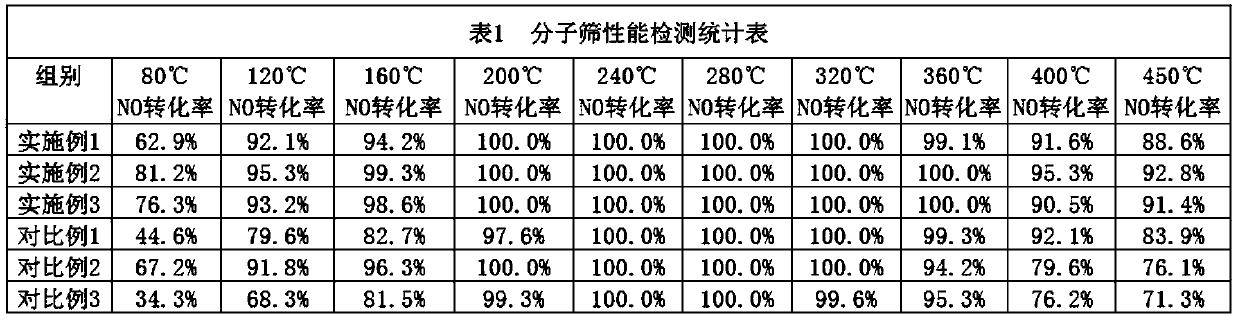

Examples

Embodiment 1

[0022] The preparation method of a kind of diesel vehicle exhaust purification molecular sieve of the present embodiment comprises the following steps:

[0023] (1) Dissolve aluminum sulfate and manganese nitrate in deionized water, then slowly add tetraethylammonium hydroxide into the solution, stir magnetically for 30 minutes, then add sodium hydroxide, stir for 30 minutes, add silica sol, mix the gel and stir 2h to obtain the precursor solution;

[0024] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal reaction kettle, place it in a homogeneous reactor for crystallization at a temperature of 110-130° C. for 3 days, filter and wash the solution obtained after 3 days, and then Drying at 110-130°C for 4-24h, followed by calcination at 400-600°C in a muffle furnace for 2-6h to obtain untreated molecular sieves;

[0025] (3) Put the molecular sieve obtained in step (2) into a constant temperature water bath, then add 0.12mol / L ammonium nitrate solution...

Embodiment 2

[0029] The preparation method of a kind of diesel vehicle exhaust purification molecular sieve of the present embodiment comprises the following steps:

[0030] (1) Dissolve aluminum sulfate and manganese nitrate in deionized water, then slowly add tetraethylammonium hydroxide into the solution, stir magnetically for 30 minutes, then add sodium hydroxide, stir for 30 minutes, add silica sol, mix the gel and stir 2h to obtain the precursor solution;

[0031] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal reaction kettle, place it in a homogeneous reactor for crystallization at a temperature of 110-130° C. for 3 days, filter and wash the solution obtained after 3 days, and then Drying at 110-130°C for 4-24h, followed by calcination at 400-600°C in a muffle furnace for 2-6h to obtain untreated molecular sieves;

[0032] (3) Put the molecular sieve obtained in step (2) into a constant temperature water bath, then add 0.12mol / L ammonium nitrate solution...

Embodiment 3

[0036] The preparation method of a kind of diesel vehicle exhaust purification molecular sieve of the present embodiment comprises the following steps:

[0037] (1) Dissolve aluminum sulfate and manganese nitrate in deionized water, then slowly add tetraethylammonium hydroxide into the solution, stir magnetically for 30 minutes, then add sodium hydroxide, stir for 30 minutes, add silica sol, mix the gel and stir 2h to obtain the precursor solution;

[0038] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal reaction kettle, place it in a homogeneous reactor for crystallization at a temperature of 110-130° C. for 3 days, filter and wash the solution obtained after 3 days, and then Drying at 110-130°C for 4-24h, followed by calcination at 400-600°C in a muffle furnace for 2-6h to obtain untreated molecular sieves;

[0039] (3) Put the molecular sieve obtained in step (2) into a constant temperature water bath, then add 0.12mol / L ammonium nitrate solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com