Preparation method of pentakis(dimethylamino) tantalum

A technology of dimethylamino and dimethylamine, which is applied in the field of preparation of penta(dimethylamino)tantalum, can solve the problems of high risk of organolithium and unfavorable process industrialization, etc., and achieve good operability, improve activity and The effect of service life and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

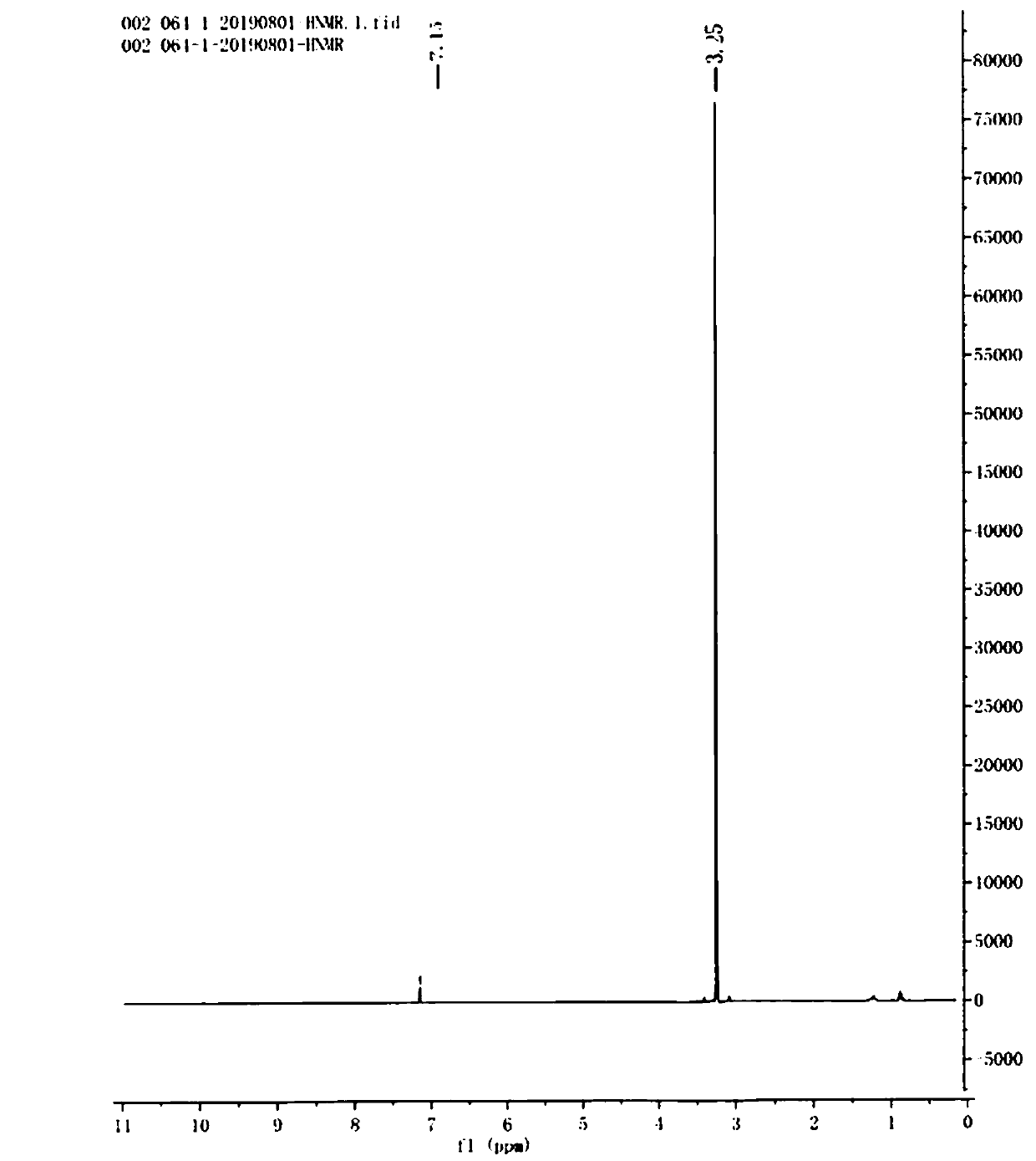

Image

Examples

Embodiment 1

[0019] A kind of preparation method of penta(dimethylamino)tantalum, its specific scheme is as follows:

[0020] In a dry nitrogen atmosphere, dissolve 9.3kg of butylmagnesium chloride in 100kg of tetrahydrofuran solution, add 0.05kg of cocatalyst, stir and mix evenly, then control the reaction temperature to minus 10°C, and pass dimethylamine gas into the solution to consume 7.8 kg of dimethylamine, complete the reaction to obtain bis(dimethylamino)magnesium; then add 10.5kg of tantalum pentachloride into the reaction kettle, control the temperature at 5°C, and continue the reaction for 10h. After the reaction is completed, filter and remove the After the solvent is distilled off, the crude product of penta(dimethylamino)tantalum can be obtained, and the product of penta(dimethylamino)tantalum can be obtained after purification.

[0021] Its preparation method of described promoter is as follows:

[0022] Take 400Kg of 0.3mol / L potassium iodide solution, add 1Kg of sodium me...

Embodiment 2

[0029] A kind of preparation method of penta(dimethylamino)tantalum, its specific scheme is as follows:

[0030] In a dry nitrogen atmosphere, dissolve 11.8kg of butylmagnesium chloride in 130kg of tetrahydrofuran solution, add 0.25kg of cocatalyst, stir and mix evenly, then control the reaction temperature to minus 20°C, and pass dimethylamine gas into the solution to consume 10.8 kg of dimethylamine, complete the reaction, and obtain bis(dimethylamino)magnesium; then add 14.5kg of tantalum pentachloride into the reaction kettle, control the temperature at 20°C, and continue the reaction for 15 hours. After the reaction is completed, filter and remove the After the solvent is distilled off, the crude product of penta(dimethylamino)tantalum can be obtained, and the product of penta(dimethylamino)tantalum can be obtained after purification.

[0031] Its preparation method of described promoter is as follows:

[0032] Take 300Kg of 0.1mol / L potassium iodide solution, add 0.3Kg ...

Embodiment 3

[0039] A kind of preparation method of penta(dimethylamino)tantalum, its specific scheme is as follows:

[0040]In a dry nitrogen atmosphere, dissolve 14.1kg of butylmagnesium chloride in 150kg of tetrahydrofuran solution, add 0.5kg of cocatalyst, stir and mix evenly, then control the reaction temperature to minus 30°C, and pass dimethylamine gas into the solution to consume 12.8 kg of dimethylamine, complete the reaction to obtain bis(dimethylamino)magnesium; then add 17.5kg of tantalum pentachloride into the reaction kettle, control the temperature at 30°C, and continue the reaction for 20h. After the reaction is completed, filter and remove the After the solvent is distilled off, the crude product of penta(dimethylamino)tantalum can be obtained, and the product of penta(dimethylamino)tantalum can be obtained after purification.

[0041] Described cocatalyst is a kind of nanoscale cuprous iodide particle, and its preparation method is as follows:

[0042] Take 500Kg of 0.5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com