A high-temperature-resistant, anti-aging low-voc polyurethane anti-corrosion coating

An anti-corrosion coating and anti-aging technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of poor heat resistance of epoxy resin, excellent anti-aging performance, and decreased adhesion, and achieve low VOC content , Anti-aging performance improvement, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-temperature-resistant, anti-aging low-VOC polyurethane anti-corrosion coating consists of the following components in parts by weight:

[0028] Component A: 12 parts of polyester polyol resin; 1.25 parts of nano-titanium dioxide; 1.25 parts of nano-silicon carbide; 50 parts of talc; 23 parts of solvent; 1.5 parts of AT-203;

[0029] Component B: 9 parts of solvent-free isocyanate resin (Basonat HI 100 ap).

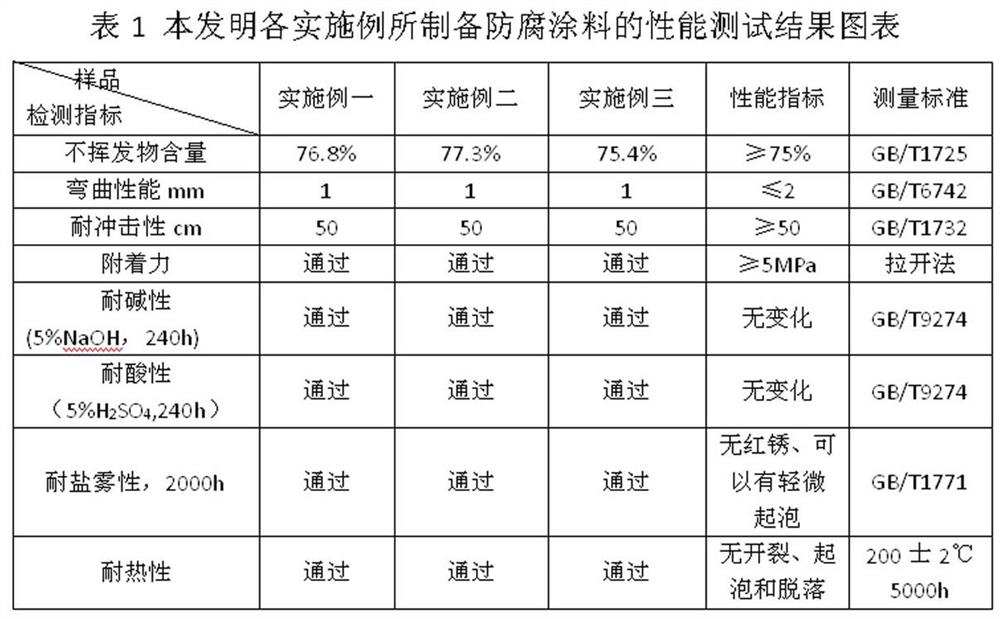

[0030] After the above-mentioned components A and B were mixed and stirred evenly, a sample board was prepared, and then the sample board was cured for 7 days, and the performance test was carried out. The performance data of the anti-corrosion paint film on the surface of the sample board are shown in Table 1 below.

Embodiment 2

[0032] A high-temperature-resistant, anti-aging low-VOC polyurethane anti-corrosion coating consists of the following components in parts by weight:

[0033] Component A: 18 parts of polyester polyol resin; 1 part of nano titanium dioxide; 1 part of nano silicon carbide; 40 parts of mica iron oxide; 20 parts of solvent; 1 part of AT-203; 1 part of organic bentonite; 0.45 parts of KH560.

[0034] Component B: 8 parts of solvent-free isocyanate resin (Basonat HI 100 ap).

[0035] After the above-mentioned components A and B were mixed and stirred evenly, a sample board was prepared, and then the sample board was cured for 7 days, and the performance test was carried out. The performance data of the anti-corrosion paint film on the surface of the sample board are shown in Table 1 below.

Embodiment 3

[0037] A high-temperature-resistant, anti-aging low-VOC polyurethane anti-corrosion coating consists of the following components in parts by weight:

[0038] Component A: 18 parts of polyester polyol resin; 1.4 parts of nano-titanium dioxide; 1.4 parts of nano-silicon carbide; 33 parts of talc powder; 23 parts of mica powder; 30 parts of solvent; 0.5 parts of AT-203; share.

[0039] Component B: 14 parts of solvent-free isocyanate resin (Basonat HI 100 ap).

[0040] After mixing and stirring the above-mentioned components A and B evenly, prepare a sample plate, then cure the sample plate for 7 days, and conduct a performance test. The performance data of the anti-corrosion paint film on the surface of the sample plate are as follows figure 1 Shown in Table 1.

[0041] attached by figure 1 It can be known from the tabular data in: the anticorrosion coating of the present invention has carried out 5000 hours heat-resistant aging test at 200 ± 2 ℃. The test results show that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com