Positive-ion gas release type double-effect composite fresh-keeping film

A composite preservation and gas release technology, applied in film/sheet release coatings, film/sheet adhesives, coatings, etc. and other problems, to achieve the effect of improving the humid environment and inhibiting the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

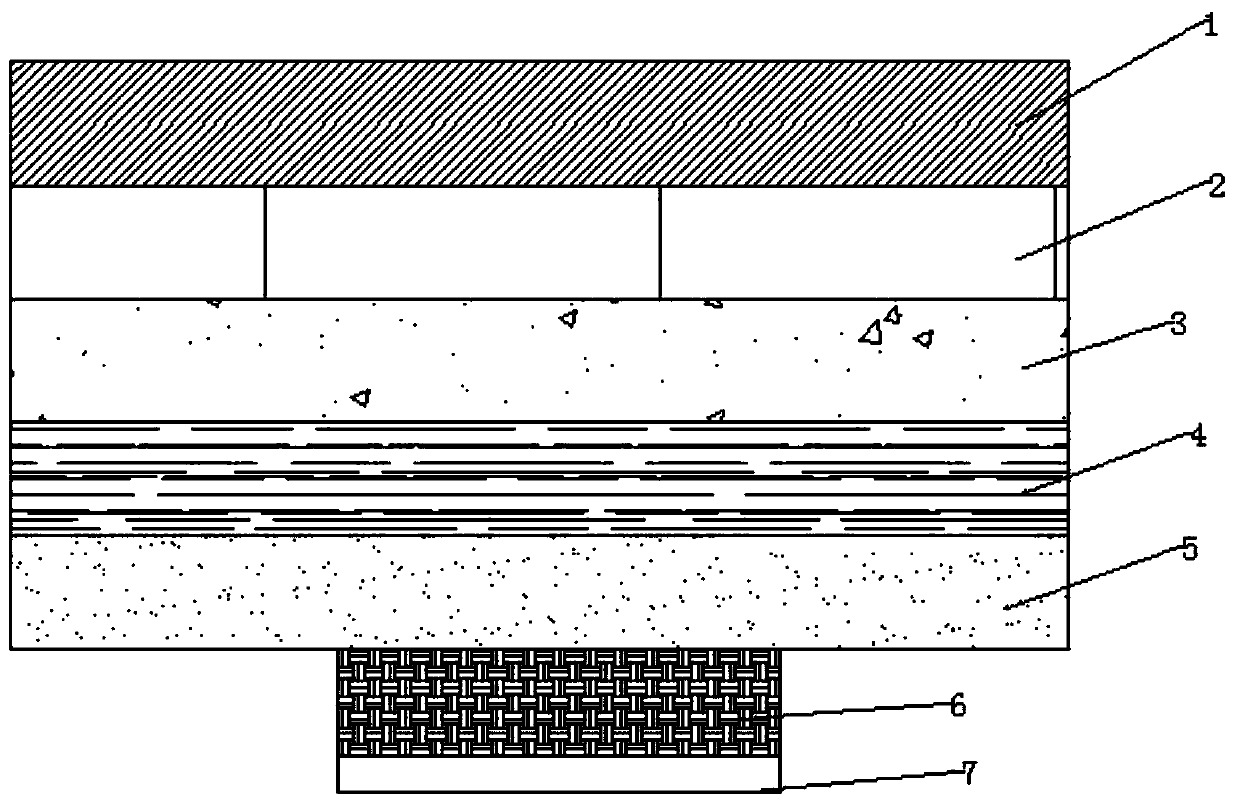

[0034] A positive ion gas release type double-effect composite fresh-keeping film, such as figure 1 As shown, it includes the main body of the film and the self-adhesive layer. The self-adhesive layer is set on the main body of the film; the main body of the film is a layer structure, which includes anti-fog layer 1, composite fresh-keeping coating 2, and polymer water-absorbing layer 3 from bottom to top. , slow release layer 4, isolation layer 5;

[0035] The anti-fog layer 1 is coated paper, and the coated film is set outward; the composite fresh-keeping coating 2 includes 10g ethylene-vinyl acetate copolymer, 1g C 4 h 6 and 1g polyhexamethylene biguanide hydrochloride and 0.2g citric acid; the polymer water-absorbing layer 3 is 10g polymer water-absorbing resin; the slow-release layer 4 is composed of 20g pyrosulfite, 1g polyethylene glycol, 5g paraffin, Composed of cyclodextrin and 1g of gum arabic; the isolation layer 5 is a polyester film with a thickness of 0.09-0.1 ...

Embodiment 2

[0042] The structure of a positive ion gas release type double-effect composite fresh-keeping film is the same as that of Example 1, and the formula of this example is:

[0043] The anti-fog layer 1 is coated paper, and the coating is set outward; the composite fresh-keeping coating 2 includes 10g natural rubber, 2gC 4 h 6and 1g polyhexamethylene biguanide propionate and 0.5g citric acid; the polymer water-absorbing layer 3 is 10g polymer water-absorbing resin; the slow-release layer 4 is made of 20g pyrosulfite, 20g bisulfite, 5g modified corn Starch, 5g glycerin, 15g paraffin, 20g ethyl cellulose and 5g polyvinyl acetate; the isolation layer 5 is a polypropylene film with a thickness of 0.09-0.1mm; the self-adhesive coating 6 is a solvent-free acrylic pressure-sensitive Glue is arranged on the isolation layer 5, and the self-adhesive coating 6 is also pasted with a self-adhesive film 7.

[0044] The preparation method and usage method are the same as in Example 1.

Embodiment 3

[0046] The structure of a positive ion gas release type double-effect composite fresh-keeping film is the same as that of Example 1, and the formula of this example is:

[0047] The anti-fog layer 1 is coated paper, and the coating is set outward; the composite fresh-keeping coating 2 includes 10g polyurethane binder, 3g C 4 h 6 And 2g polyhexamethylene guanidine nitrate and 1g citric acid; The polymer water-absorbing layer 3 is 10g polymer water-absorbing resin; PE, 30g of carboxymethylated corn modified starch, 5g of gum arabic, and 5g of polyvinyl acetate; the isolation layer 5 is a polypropylene film with a thickness of 0.09-0.1mm; the self-adhesive coating 6 is a solvent-free acrylic pressure-sensitive Glue is arranged on the isolation layer 5, and the self-adhesive coating 6 is also pasted with a self-adhesive film 7.

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com