An opaque film for electromagnetic shielding

A transparent film, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, shielding materials, electrical components, etc., can solve the problems of affecting the durability of materials and continuous electromagnetic shielding efficiency, difficult to achieve industrialization, easy to peel and prepare costs, etc. Achieving good electromagnetic shielding efficiency, isolation impact, and long-lasting electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

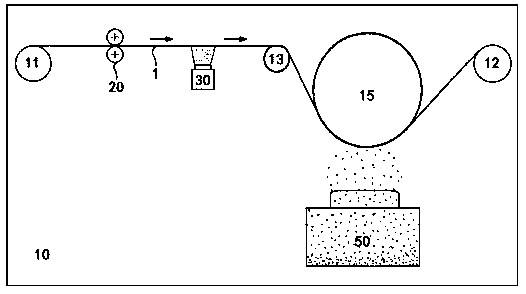

[0029] According to the ratio, prepare 65 parts by weight of polypropylene, 15 parts by weight of maleic anhydride modified polypropylene, 15 parts by weight of Ni powder and 5 parts by weight of Fe 3 O 4 Put it into a screw extruder, knead at 220°C and make a masterbatch, and then use a film blowing machine to make a film with a thickness of about 100μm as a polymer film matrix. Then in figure 1 In the vacuum deposition system shown, the two main surfaces of the polymer film substrate are coated with silicon oxide film by thermal evaporation. The pressure roller adopts an elastic rubber roller (temperature is 70℃) to apply the polymer film substrate. Extrusion force of 3MPa, and then through corona treatment (O 2 Plasma and then use a blown film machine to make a film with a thickness of about 100 μm as a polymer film matrix. (O 2 Plasma, the power is 300W, the oxygen partial pressure is 100Pa), the deposition roller maintains its surface temperature at 5°C by forced cooling, a...

Embodiment 2

[0031] According to the ratio, prepare 60 parts by weight of polypropylene, 20 parts by weight of maleic anhydride modified polypropylene, 12 parts by weight of Ni powder and 8 parts by weight of Fe 3 O 4 Put it into a screw extruder, knead at 220°C and make a masterbatch, and then use a film blowing machine to make a film with a thickness of about 100μm as a polymer film matrix. Then in figure 1 In the vacuum deposition system shown, the two main surfaces of the polymer film substrate are coated with silicon oxide film by thermal evaporation. The pressure roller adopts an elastic rubber roller (temperature is 70℃) to apply the polymer film substrate. Extrusion force of 3MPa, and then through corona treatment (O 2 Plasma, the power is 300W, the oxygen partial pressure is 100Pa), the deposition roller maintains its surface temperature at 5°C by forced cooling, and evaporates the silicon oxide powder placed in the crucible (heated to 1000°C) on the surface of the polymer film subst...

Embodiment 3

[0033] According to the ratio, prepare 80 parts by weight of polypropylene, 15 parts by weight of Ni powder and 5 parts by weight of Fe 3 O 4 Put it into a screw extruder, knead at 220°C and make a masterbatch, and then use a film blowing machine to make a film with a thickness of about 100μm as a polymer film matrix. Then in figure 1 In the vacuum deposition system shown, the two main surfaces of the polymer film substrate are coated with silicon oxide film by thermal evaporation. The pressure roller adopts an elastic rubber roller (temperature is 70℃) to apply the polymer film substrate. Extrusion force of 3MPa, and then through corona treatment (O 2 Plasma, the power is 300W, the oxygen partial pressure is 100Pa), the deposition roller maintains its surface temperature at 5-15°C by forced cooling, and evaporates the silicon oxide powder placed in the crucible (heated to 1000°C) on the polymer film A silicon oxide coating film is deposited on the surface of the substrate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com