Catalytic nitrogen carrier suitable for coal chemical looping ammonia production and preparation method thereof

A catalytic carrier, chemical chain technology, applied in chemical instruments and methods, ammonia preparation/separation, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, low conversion efficiency, low single-pass conversion rate, etc. High gas conversion rate, uniform distribution and good fluidization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 2kg of γ-alumina, 0.3kg of calcium fluoride, and 7.7kg of titanium oxide, add 100l of water, place them on a stirrer for stirring, and heat at 70°C. After 2h, put the suspension into In a muffle furnace, heat it to 500°C, pass argon gas for calcination, calcinate at a constant temperature for 12 hours, take it out, and finally put the bulk sample into a mortar and fully grind it to obtain a powdery sample, and finally sieve the sample and keep 3 ~4 μm samples.

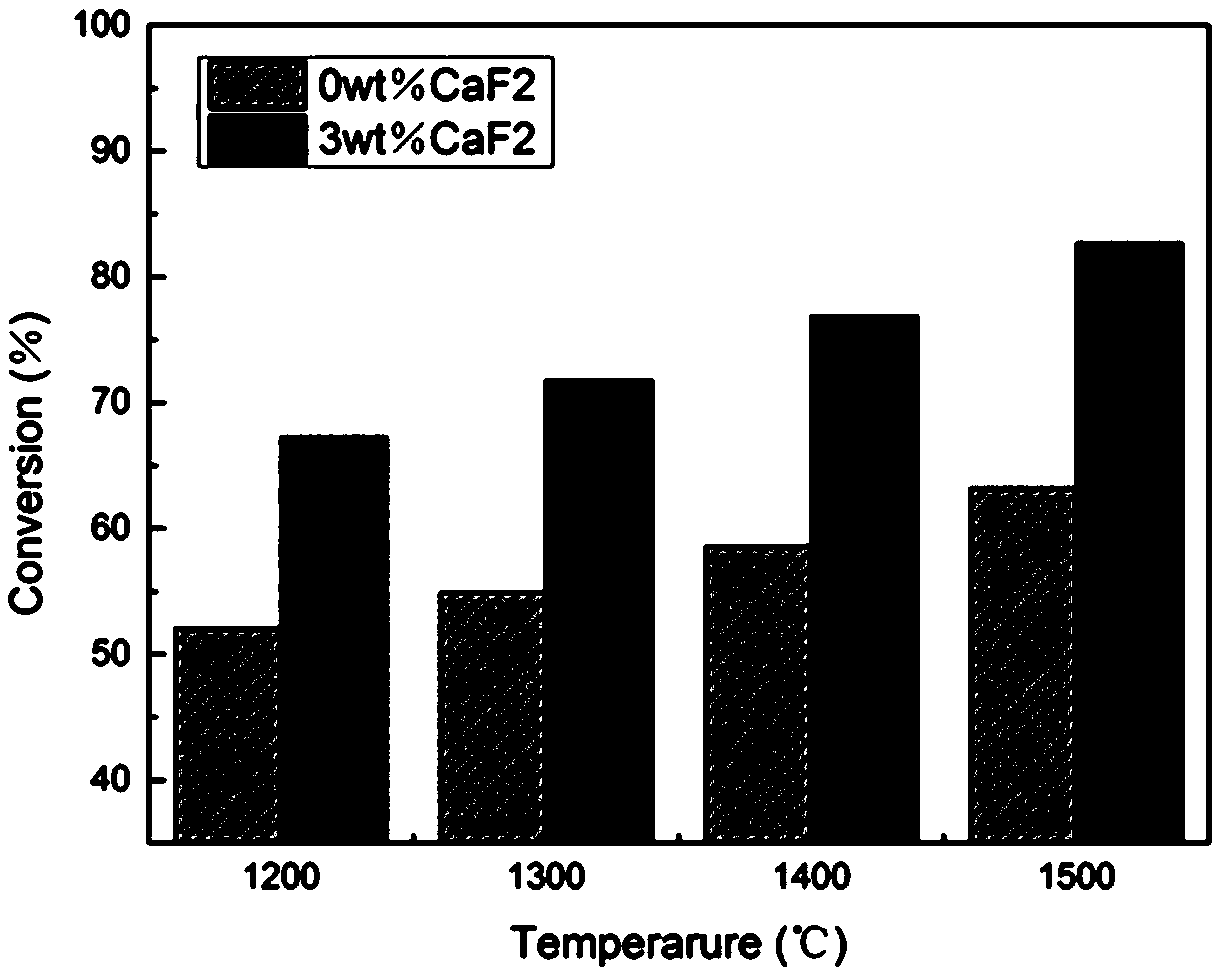

[0031] The performance test of nitrogen absorption reaction and nitrogen release reaction was carried out on the catalytic nitrogen carrier prepared in Example 1. like figure 1 As shown, the reaction temperature was from 1200 to 1500° C., the flow rate of nitrogen was 200 ml / min, the mass of γ-alumina was 0.5 g, and the mass of coke was 0.16 g. Compared with the catalytic nitrogen carrier prepared without adding calcium fluoride, the catalytic nitrogen carrier prepared in Example 1 has a significantly hi...

Embodiment 2

[0034] Weigh 2kg of γ-alumina, 0.3kg of yttrium oxide, and 7.7kg of titanium oxide, add 100 l of water, place them on a stirrer for stirring, and heat at 70 °C, and put the suspension into a horse after 2 hours. In a Furnace, heated to 500°C, calcined with argon gas, calcined at a constant temperature for 12 hours, taken out, and finally put the bulk sample into a mortar and fully ground to obtain a powdery sample, and finally sieved the sample and retained 3~ 4 μm samples.

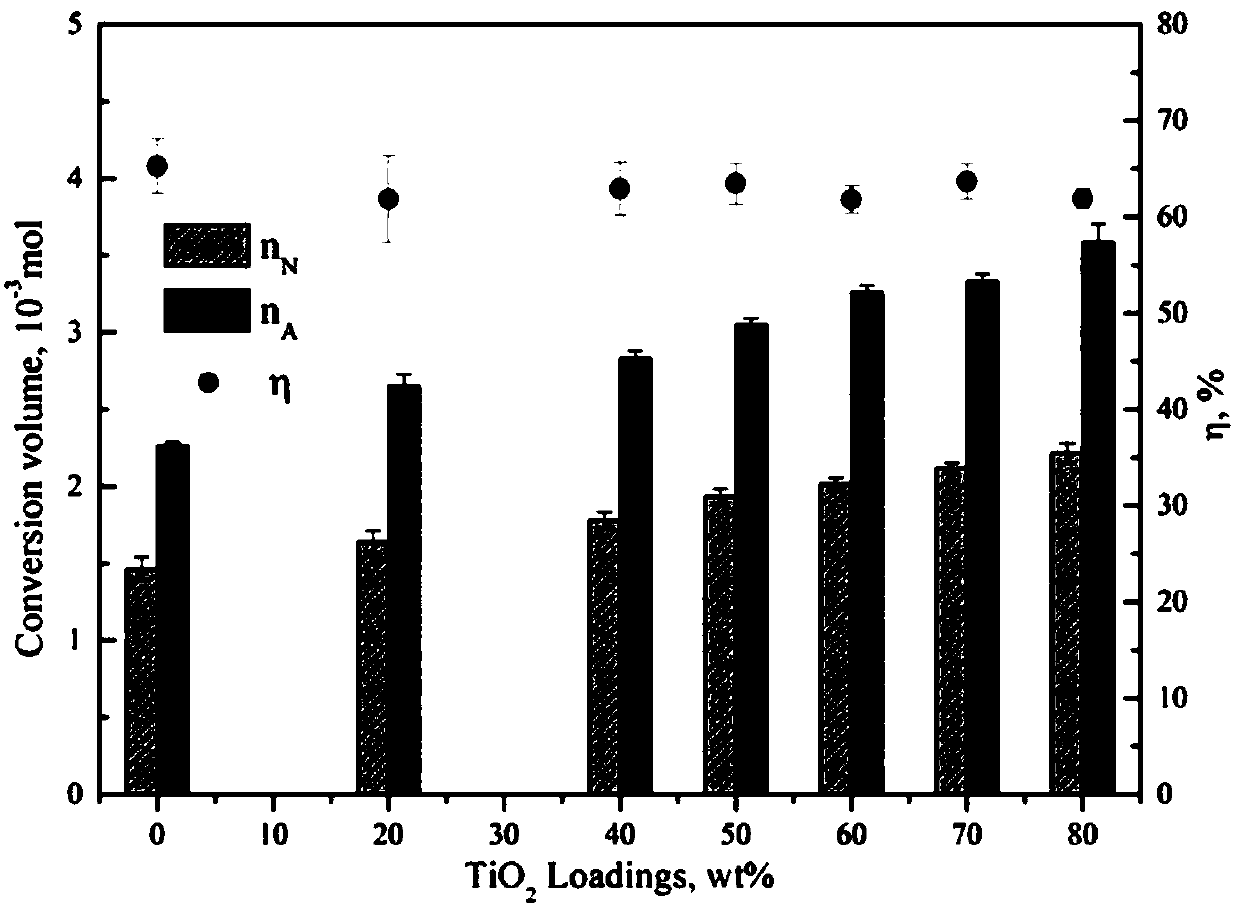

[0035] During the nitrogen release reaction, the conversion rate of ammonia gas increases with the mass proportion of the titanium oxide carrier. When the mass content of titanium oxide accounts for 80%, the conversion rate of ammonia gas can reach 60%.

Embodiment 3

[0037] Weigh 3kg of γ-alumina, 0.3kg of calcium fluoride, 6.7kg of titanium oxide, add 100l of water, place it on a stirrer for stirring, and heat at 70°C, after 2h, put the suspension into In a muffle furnace, heat it to 500°C, pass argon gas for calcination, calcinate at a constant temperature for 12 hours, take it out, and finally put the bulk sample into a mortar and fully grind it to obtain a powdery sample, and finally sieve the sample and keep 3 ~4 μm samples.

[0038] In the process of nitrogen release reaction, the conversion rate of ammonia gas increases with the increase of the mass proportion of titanium oxide carrier. When the mass content of titanium oxide accounts for 70%, the conversion rate of ammonia gas can reach 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com