Lithium manganese oxide battery positive electrode sheet and preparation method thereof

A technology of lithium manganate battery and positive electrode sheet, which is applied in battery electrodes, electrode manufacturing, electrode current collector coating and other directions, can solve the problems such as not meeting the needs of green industry development, easy to swell electronic ion conductivity, and toxicity, etc. Achieving good cycle rate performance, improving bonding performance and mechanical stability, and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

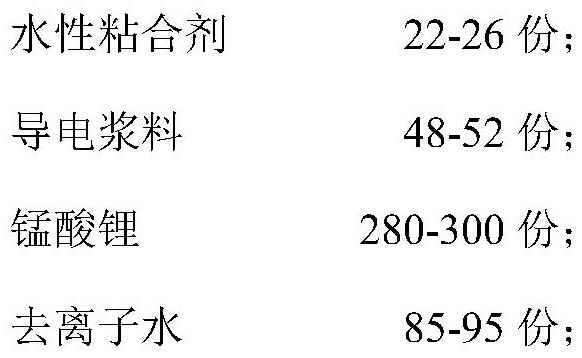

[0052] A lithium manganese oxide battery positive electrode sheet, the raw material components are as follows in parts by weight.

[0053]

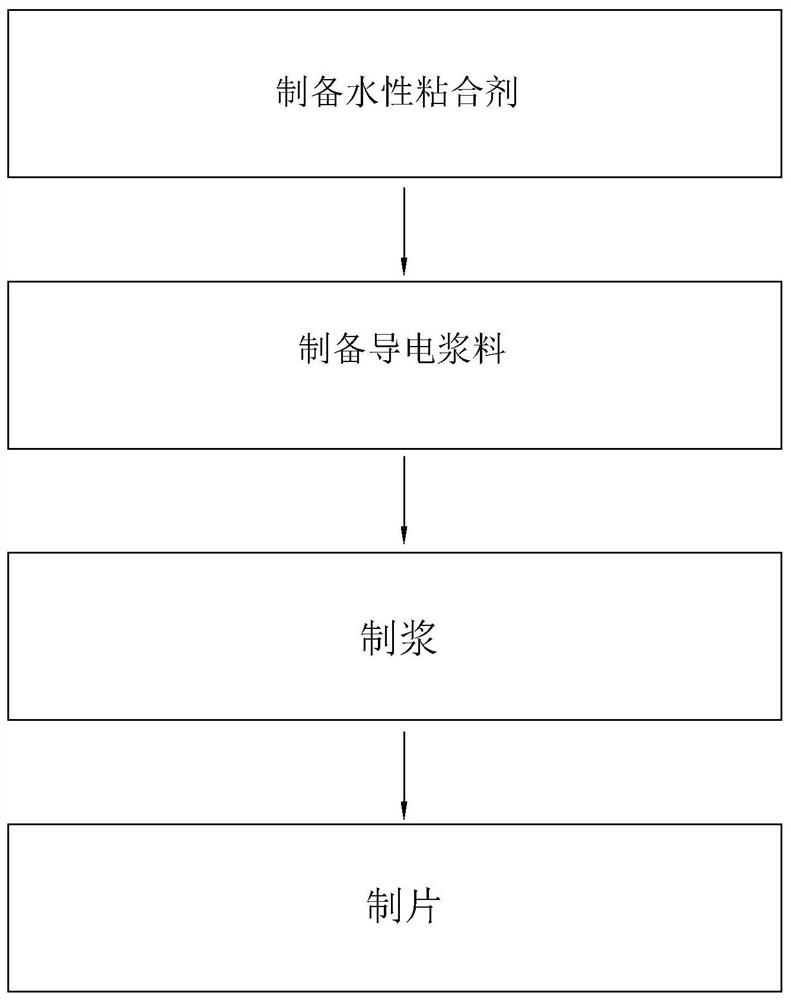

[0054] Such as figure 1 Shown, the preparation method of this lithium manganese oxide battery positive plate comprises the following steps:

[0055] S1, preparation of water-based adhesive: mix carboxymethyl chitosan, polyethylene glycol and cross-linking agent SaC-100 evenly at 70°C, and keep warm for 0.5h;

[0056] S2, preparation of conductive paste: (1) adding sulfur-doped carbon nanotubes in parts by weight to Pingping plus O and stirring evenly, grinding in a colloid mill for 1h and mixing evenly to obtain a mixed slurry; (2) adding graphite to the mixed slurry olefin, continue to grind in the colloid mill for 1h and mix evenly to obtain the conductive paste;

[0057] S3, pulping: Add water-based adhesive to the mixing tank, add 75 parts of deionized water, stir and disperse at 100rpm for 10min, add conductive paste and stir an...

Embodiment 2

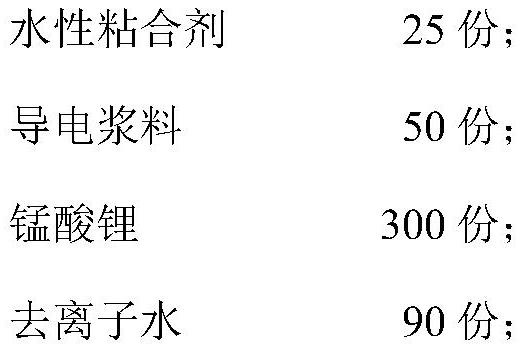

[0060] A lithium manganese oxide battery positive electrode sheet, the raw material components are as follows in parts by weight.

[0061]

[0062] The preparation method of the lithium manganate battery positive plate comprises the following steps:

[0063] S1, preparation of water-based adhesive: mix carboxymethyl chitosan, polyethylene glycol and cross-linking agent SaC-100 evenly at 75°C, and keep warm for 0.8h;

[0064] S2, preparation of conductive paste: (1) add sulfur-doped carbon nanotubes in parts by weight to Pingping plus O and stir evenly, grind in a colloid mill for 1.2h and mix evenly to obtain a mixed slurry; (2) Add to the mixed slurry Graphene, continue grinding in the colloid mill for 1.2h and mix evenly to obtain the conductive paste;

[0065] S3, pulping: Add water-based adhesive to the mixing tank, add 75 parts of deionized water, stir and disperse at 100rpm for 10min, add conductive paste and stir and disperse at 500rpm for 30min, add 180 parts of li...

Embodiment 3

[0068] A lithium manganese oxide battery positive electrode sheet, the raw material components are as follows in parts by weight.

[0069]

[0070] The preparation method of the lithium manganate battery positive plate comprises the following steps:

[0071] S1, preparation of water-based adhesive: mix carboxymethyl chitosan, polyethylene glycol and cross-linking agent SaC-100 evenly at 80°C, and keep warm for 1 hour;

[0072] S2, preparation of conductive paste: (1) add sulfur-doped carbon nanotubes in parts by weight to Pingping plus O and stir evenly, grind in a colloid mill for 1.5h and mix evenly to obtain a mixed slurry; (2) Add to the mixed slurry Graphene, continue to grind 1.5h in colloid mill and mix evenly, obtain conductive paste;

[0073] S3, pulping: Add water-based adhesive to the mixing tank, add 78 parts of deionized water, stir and disperse at 100rpm for 13min, add conductive paste and stir and disperse at 500rpm for 35min, add 175 parts of lithium mangan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com