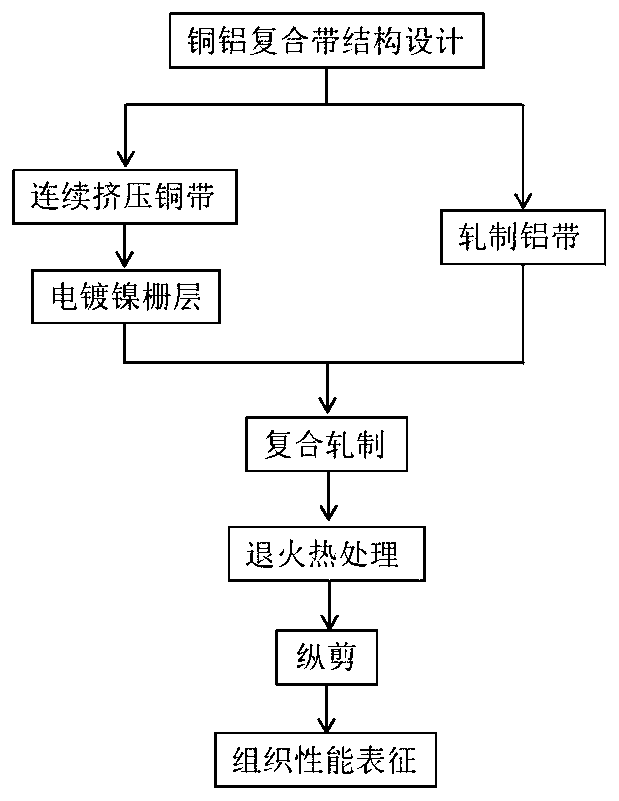

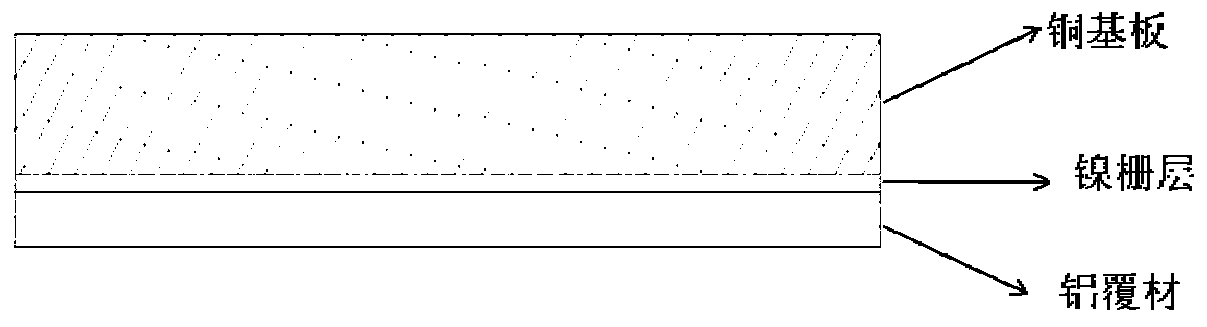

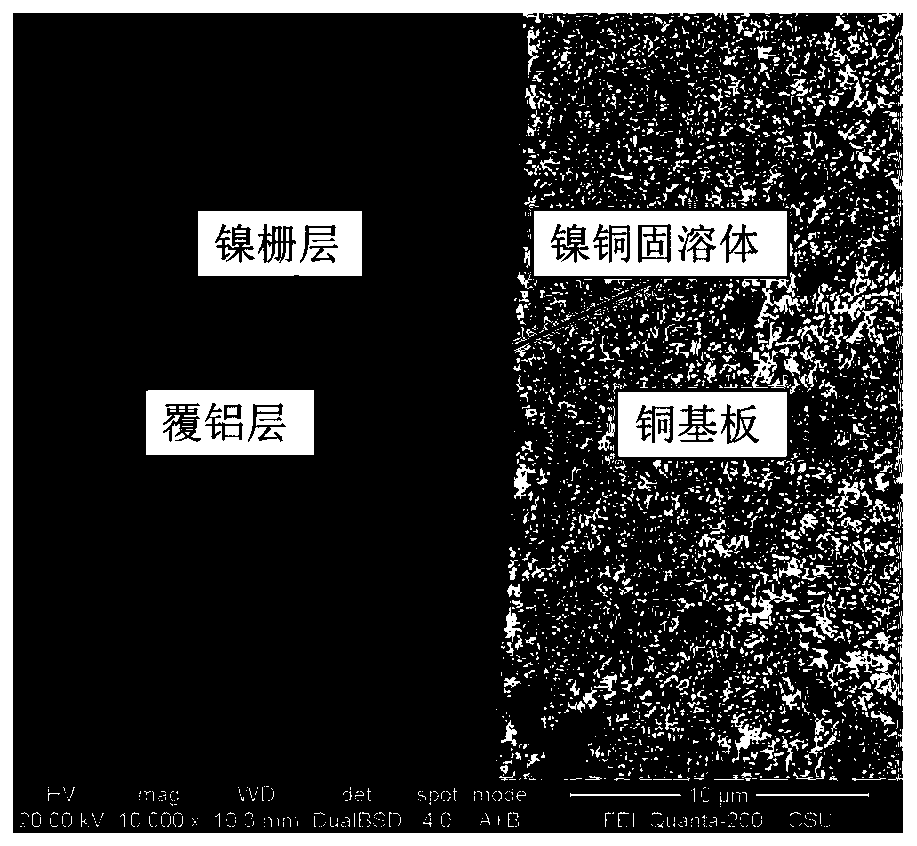

Copper-aluminum composite plate strip with added nickel grid layer and continuous production method thereof

A technology of copper-aluminum composite board and production method, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of affecting the performance of materials, the reduction of the bonding strength of composite boards and strips, and achieve the convenience of deep drawing And bending processing, processing and heat treatment process simplification, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of a copper-aluminum composite strip with a nickel grid layer added with a thickness of 1.2mm

[0037] 1. Raw materials: select copper plate with a thickness of 4mm and a width of 50mm as the raw material of the copper substrate; an aluminum strip with a thickness of 0.5mm and a width of 10mm as the raw material of the aluminum cladding;

[0038] 2. Electroplated nickel grid layer:

[0039] ① Wash off the oil on the surface of the copper plate with 10% sodium hydroxide solution, and rinse until neutral;

[0040] ②Soak in 10% dilute nitric acid solution for 20s to remove the oxide layer on the surface of the copper plate and rinse until neutral;

[0041]③ Rinse with alcohol and dry with cold air for later use;

[0042] ④Paste a special non-adhesive protective film on the non-composite area of the copper plate surface for protection;

[0043] ⑤Put the copper plate as the cathode into the electroplating tank. The formula of the electroplating so...

Embodiment 2

[0049] Example 2: Preparation of a copper-aluminum composite strip with a nickel grid layer added with a thickness of 0.8mm

[0050] 1. Raw material: select copper plate with a thickness of 2.4mm and a width of 50mm as the copper base material; aluminum strip with a thickness of 0.4mm and a width of 15mm as the aluminum cladding material;

[0051] 2. Electroplated nickel grid layer:

[0052] ① Wash off the oil on the surface of the copper plate with 10% sodium hydroxide solution, and rinse until neutral;

[0053] ②Soak in 10% dilute nitric acid solution for 20s to remove the oxide layer on the surface of the copper plate and rinse until neutral;

[0054] ③ Rinse with alcohol and dry with cold air for later use;

[0055] ④Paste a special non-adhesive protective film on the non-composite area of the copper plate surface for protection;

[0056] ⑤Put the copper plate as the cathode into the electroplating tank. The formula of the electroplating solution is: 280g / L nickel sul...

Embodiment 3

[0062] Example 3: Preparation of a copper-aluminum composite strip with a nickel grid layer added with a thickness of 0.5 mm

[0063] 1. Raw materials: select copper plate with a thickness of 2mm and a width of 50mm as the raw material of the copper substrate; an aluminum strip with a thickness of 0.3mm and a width of 10mm as the raw material of the aluminum cladding;

[0064] 2. Electroplated nickel grid layer:

[0065] ① Wash off the oil on the surface of the copper plate with 10% sodium hydroxide solution, and rinse until neutral;

[0066] ②Soak in 10% dilute nitric acid solution for 20s to remove the oxide layer on the surface of the copper plate and rinse until neutral;

[0067] ③ Rinse with alcohol and dry with cold air for later use;

[0068] ④Paste a special non-adhesive protective film on the non-composite area of the copper plate surface for protection;

[0069] ⑤Put the copper plate as the cathode into the electroplating tank. The formula of the electroplating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com