Pine dendritic samarium oxide graphene sulfur gel structure material and its preparation method and application

A gel structure and graphene technology, applied in graphene, chemical instruments and methods, structural parts, etc., can solve the problems of low sulfur loading, low cycle life, and poor cycle performance, so as to improve electrochemical performance, Improve the sulfur loading capacity and promote the effect of reaction conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of reduced graphene oxide-samarium precursor: Weigh 80 mg of graphene oxide and place it in a 100 mL beaker, then add 40 mL of deionized water, ultrasonicate for 2 hours, then take 2.5 mL of 1.6 mmol L -1 The samarium nitrate aqueous solution was placed in a 100mL beaker, the graphene oxide colloidal solution was slowly added to the samarium nitrate solution, stirred for 2 hours and mixed evenly to obtain a mixture, the mass fraction of 25% ammonia water was added dropwise until the pH reached 10, and then stirred at every 5 Add 1.3mL85mg mL dropwise at a rate of 100 microliters per minute -1 Hydrazine hydrate solution, transfer the solution to a reaction kettle and react at 180°C for 6 hours. After the reaction product is naturally cooled, centrifuged, washed, frozen, and freeze-dried, the reduced graphene oxide-samarium precursor gel is obtained.

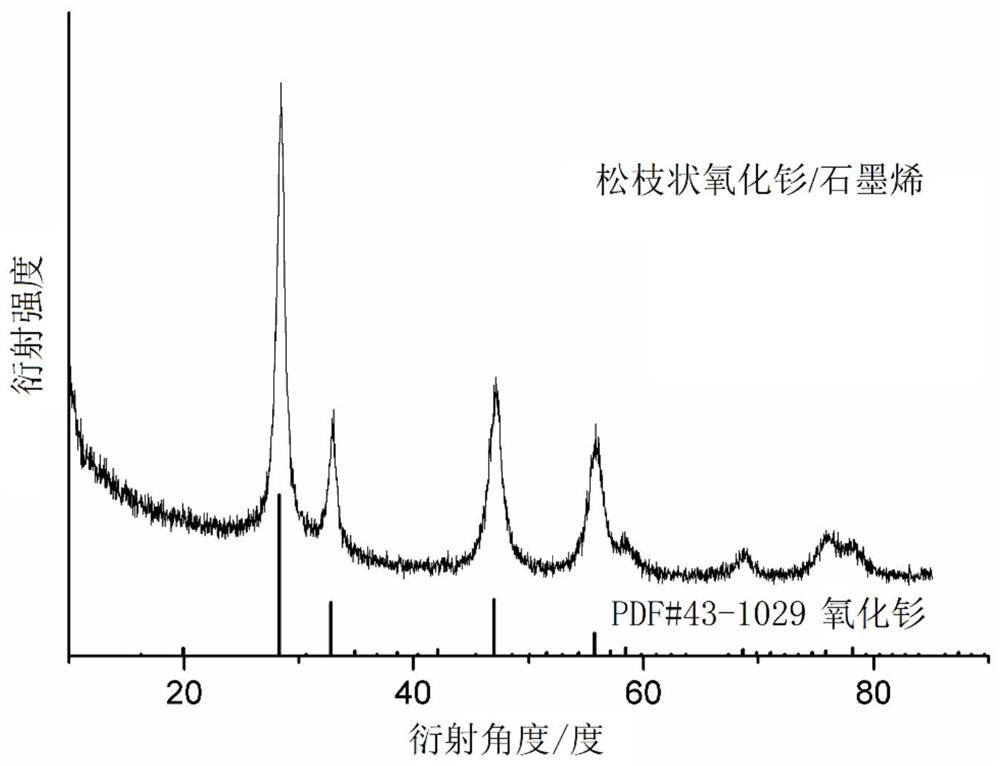

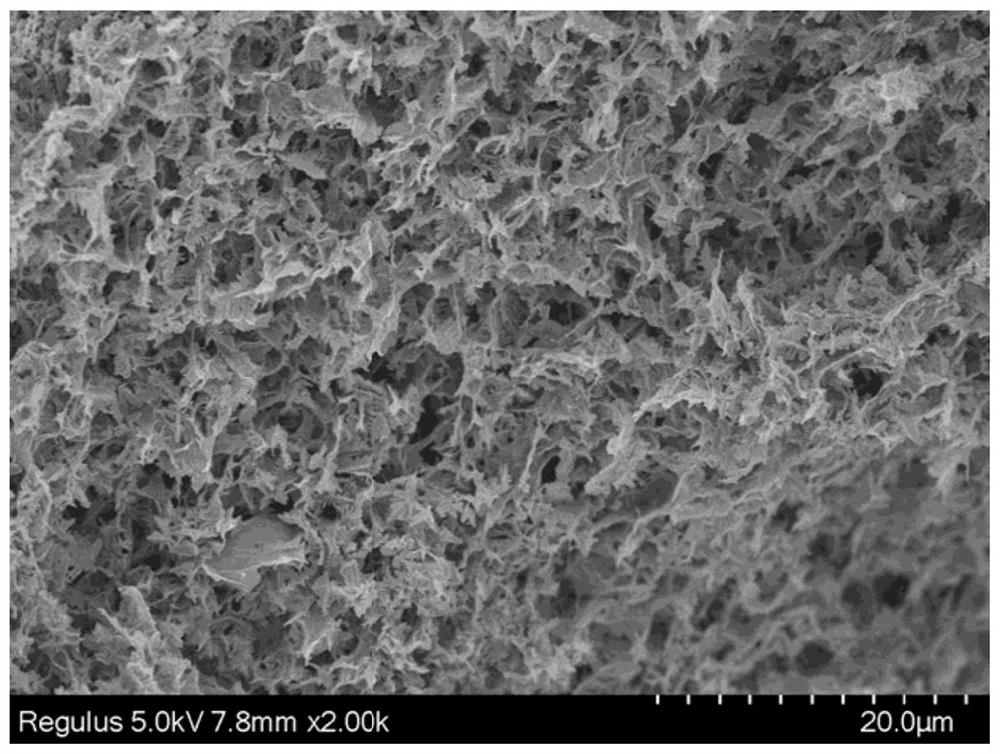

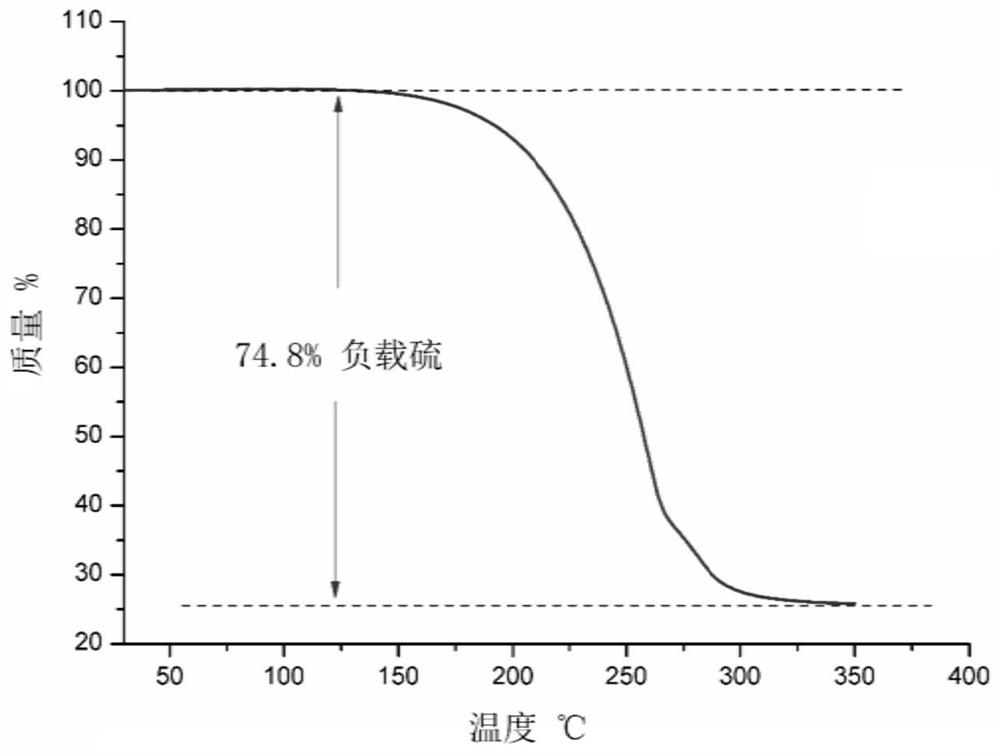

[0058] (2) Preparation of pine dendritic samarium oxide / graphene gel: place the reduced graphene oxide-sa...

Embodiment 2

[0066] (1) Preparation of reduced graphene oxide-samarium precursor: Weigh 80 mg of graphene oxide and place it in a 100 mL beaker, then add 40 mL of deionized water, ultrasonicate for 2 hours, then take 2.5 mL of 1.2 mmol L -1 The samarium nitrate aqueous solution was placed in a 100mL beaker, the graphene oxide colloidal solution was slowly added to the samarium nitrate solution, stirred for 2 hours and mixed evenly to obtain a mixture, the mass fraction of 25% ammonia water was added dropwise until the pH reached 10, and then stirred at every 5 Add 1.3mL85mg mL dropwise at a rate of 100 microliters per minute -1 Hydrazine hydrate solution, transfer the solution to a reaction kettle and react at 180°C for 6 hours. After the reaction product is naturally cooled, centrifuged, washed, frozen, and freeze-dried, the reduced graphene oxide-samarium precursor gel is obtained.

[0067] Steps (2), (3) are the same as in Example 1.

Embodiment 3

[0069] (1) Preparation of reduced graphene oxide-samarium precursor: Weigh 80 mg of graphene oxide and place it in a 100 mL beaker, then add 40 mL of deionized water, ultrasonicate for 2 hours, and then take 2.5 mL of 0.8 mmol L -1 The samarium nitrate aqueous solution was placed in a 100mL beaker, the graphene oxide colloidal solution was slowly added to the samarium nitrate solution, stirred for 2 hours and mixed evenly to obtain a mixture, the mass fraction of 25% ammonia water was added dropwise until the pH reached 10, and then stirred at every 5 Add 1.3mL85mg mL dropwise at a rate of 100 microliters per minute -1 Hydrazine hydrate solution, transfer the solution to a reaction kettle and react at 180°C for 6 hours. After the reaction product is naturally cooled, centrifuged, washed, frozen, and freeze-dried, the reduced graphene oxide-samarium precursor gel is obtained.

[0070] Steps (2), (3) are the same as in Example 1.

[0071] Through testing, the CV curve and charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com