Multilayer composite membrane and preparation method therefor

A multi-layer composite film and composite layer technology, applied in the field of food packaging materials, can solve the problems of easy peeling of multi-layer structures, affecting the packaging effect of materials, cracking, etc., and achieve the effect of maintaining mechanical properties, good mechanical properties, and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

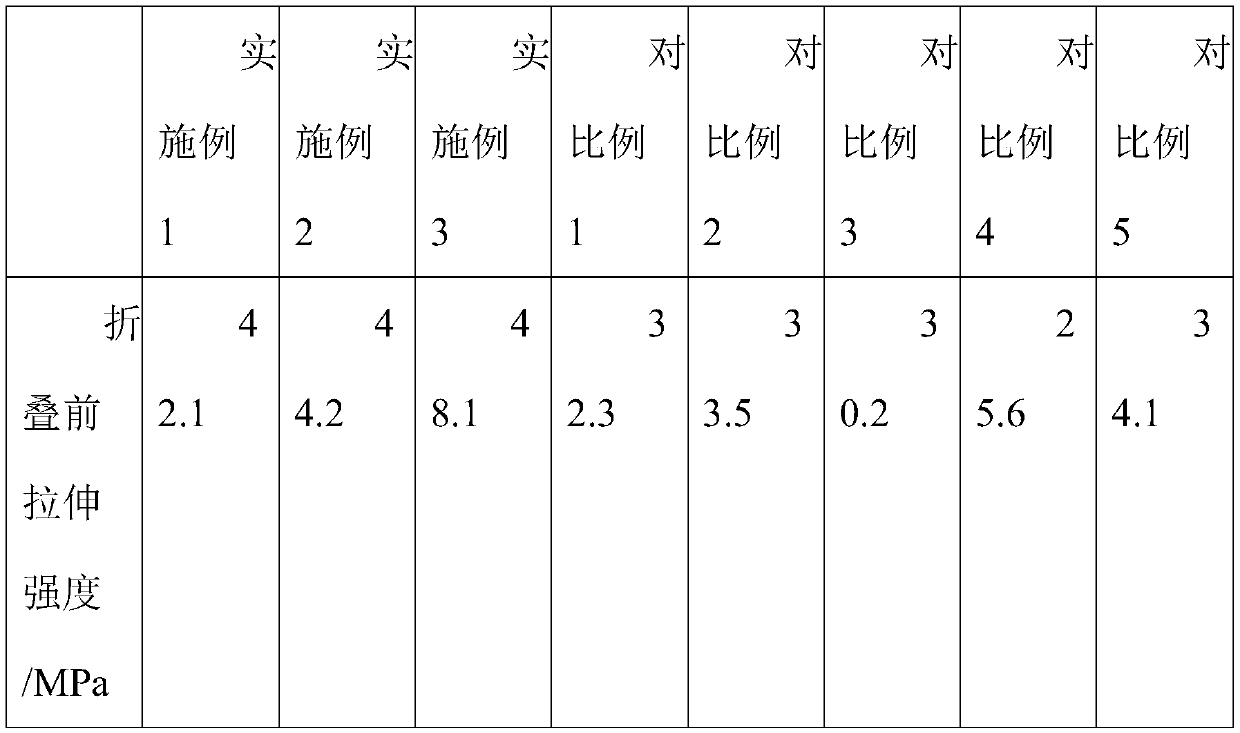

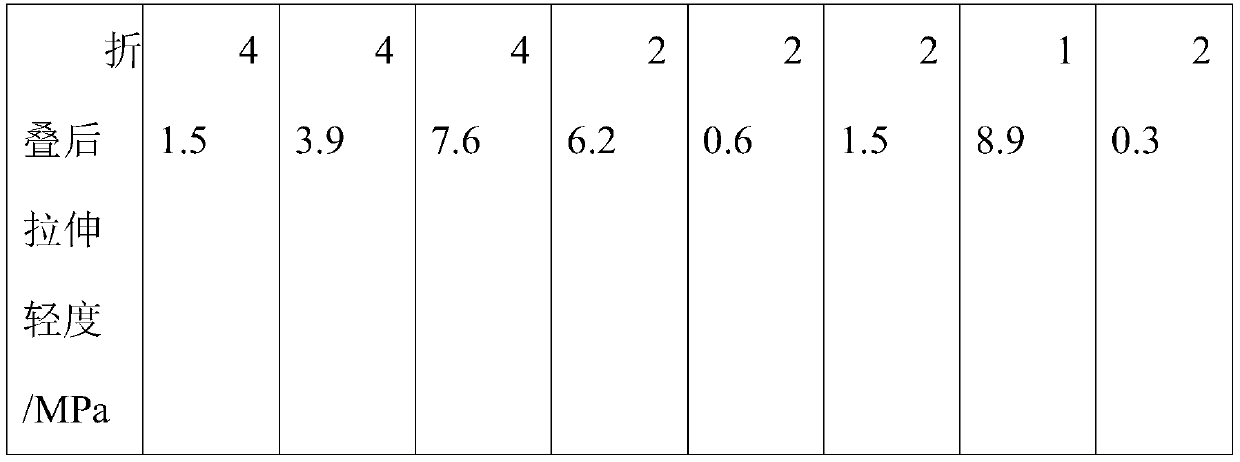

Examples

Embodiment 1

[0036]In parts by weight, take 10 parts of silicate, 8 parts of titanate, 60 parts of absolute ethanol, 10 parts of fatty acid, 20 parts of polylactic acid, 80 parts of tetrahydrofuran, and 4 parts of graphene oxide. In tetrahydrofuran, at a temperature of 55 °C and a stirring speed of 300 r / min, keep stirring and dissolving for 45 minutes, and then under stirring, add graphene oxide, silicate, titanate, anhydrous ethanol and fatty acid in sequence, and continue After stirring for 10 min, under the condition of temperature of 85 ℃, heating and refluxing for 3 h, after the reaction is over, transfer the material to the casting machine while it is still hot, and cast the film to form a film. dry to obtain a dry film;

[0037] Fix the dry film on the tensile machine, first stretch the dry film longitudinally along the dry film to 1.1 times the original length of the dry film, and then stretch the dry film laterally along the dry film to 1.1 times the original width of the dry fil...

Embodiment 2

[0046] In parts by weight, sequentially take 12 parts of silicate, 9 parts of titanate, 70 parts of absolute ethanol, 12 parts of fatty acid, 25 parts of polylactic acid, 90 parts of tetrahydrofuran, and 5 parts of graphene oxide, first add polylactic acid to In tetrahydrofuran, under the condition that the temperature is 60 °C and the stirring speed is 400 r / min, keep stirring and dissolving for 55 minutes, and then under stirring, add graphene oxide, silicate, titanate, anhydrous ethanol and fatty acid in sequence, and continue After stirring for 15min, under the condition of temperature of 88 ℃, heating and refluxing reaction for 4h, after the reaction is over, transfer the material to the casting machine while it is still hot, cast a film, control the blade distance of the casting machine to be 4mm, and then pass dry to obtain a dry film;

[0047] Fix the dry film on the tensile machine, first stretch the dry film longitudinally along the dry film to 1.1 times the original...

Embodiment 3

[0056] In parts by weight, sequentially take 15 parts of silicate, 10 parts of titanate, 80 parts of absolute ethanol, 15 parts of fatty acid, 30 parts of polylactic acid, 100 parts of tetrahydrofuran, and 6 parts of graphene oxide. In tetrahydrofuran, under the condition that the temperature is 65°C and the stirring speed is 500r / min, keep stirring and dissolve for 60min, and then under stirring, add graphene oxide, silicate, titanate, anhydrous ethanol and fatty acid in sequence, and continue After stirring for 20 min, under the condition of temperature of 90 ℃, heating and refluxing for 5 h, after the reaction is over, transfer the material to the casting machine while it is still hot, and cast the film to form a film. dry to obtain a dry film;

[0057] Fix the dry film on the tensile machine, first stretch the dry film longitudinally to 1.2 times the original length of the dry film, and then stretch the dry film laterally to 1.2 times the original width of the dry film, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com