Multi-metal tube heat tracing composite tube for radioactive fluid conveying

A fluid conveying and radioactive technology, applied in the direction of pipeline heating/cooling, pipe/pipe joint/pipe fitting, pipeline protection, etc., can solve the problems of low heating temperature, inaccurate control, small number of metal pipes, etc., and achieve effective insulation at high temperature and high temperature , flexible and convenient to use, uniform and constant temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

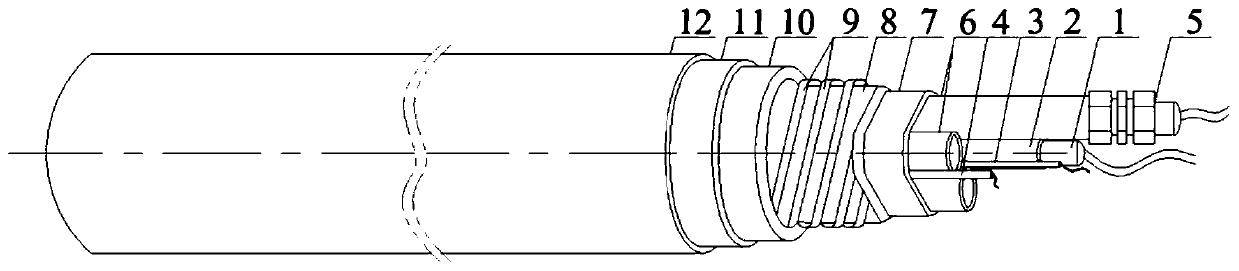

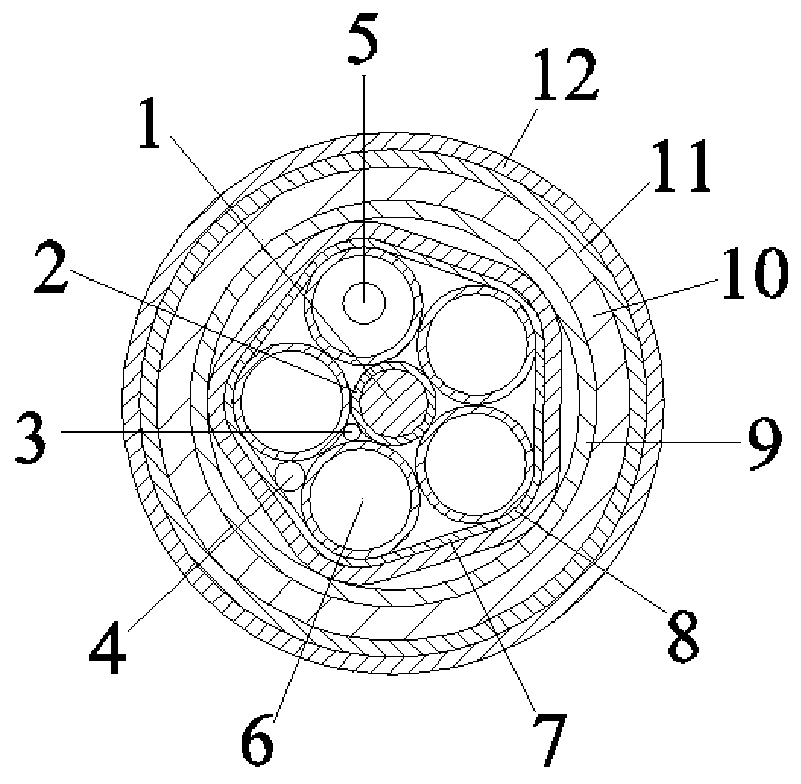

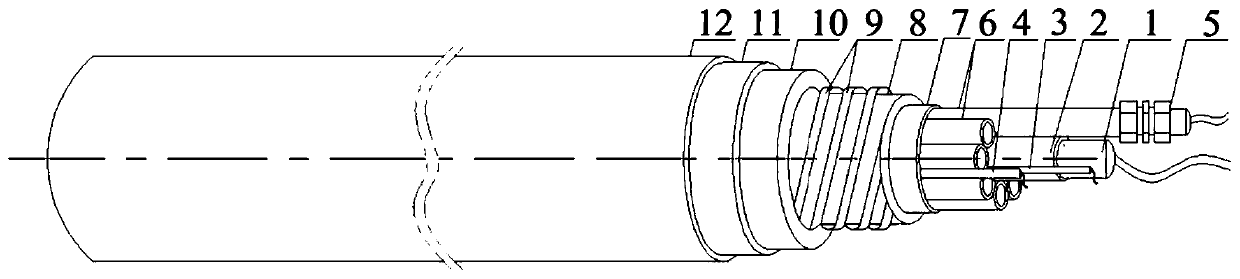

[0034] Such as Figure 1 to Figure 4 As shown, the present invention provides a multi-metal tube heating composite tube for radioactive fluid delivery, including a central heating body 1, a high-temperature insulating coating 2 that resists radiation radiation, a first thermocouple 3, and a second thermocouple 4 , the third thermocouple 5, metal tube 6, wrapped fixed layer 7, radiation protection layer 8, spiral heating body 9, insulation layer 10, metal mesh reinforcement layer 11, insulation protection layer 12 and other components.

[0035] The central heating body 1 is cylindrical, and is arranged at the axial center of the multi-metal tube heat tracing compound tube for the radioactive fluid. The central heating body 1 is an armored heating body.

[0036] The anti-ray radiation high-temperature insulating coating 2 is coated on the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com