Method for extracting unsaponifiable matter from vegetable oil and application

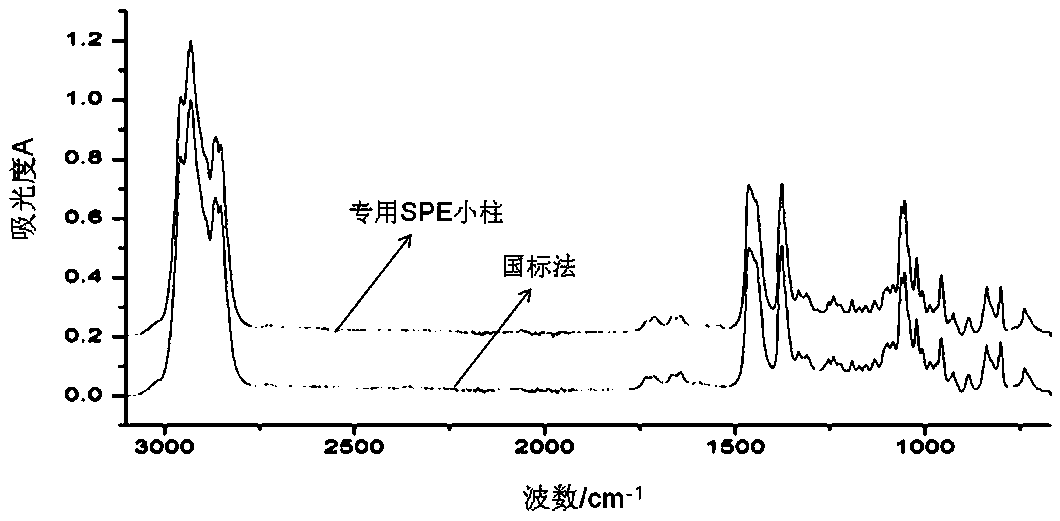

An extraction method and technology for saponification, which are applied in the field of extraction of unsaponifiables of vegetable oil, can solve the problems of long extraction period, long time consumption, complicated separation and enrichment process, etc. Simple and effective extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

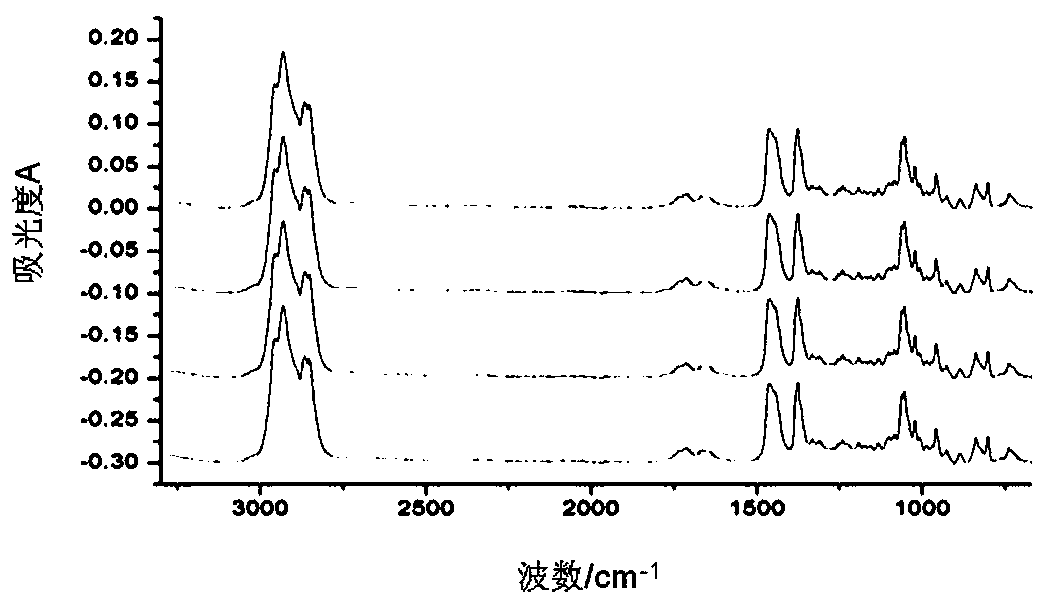

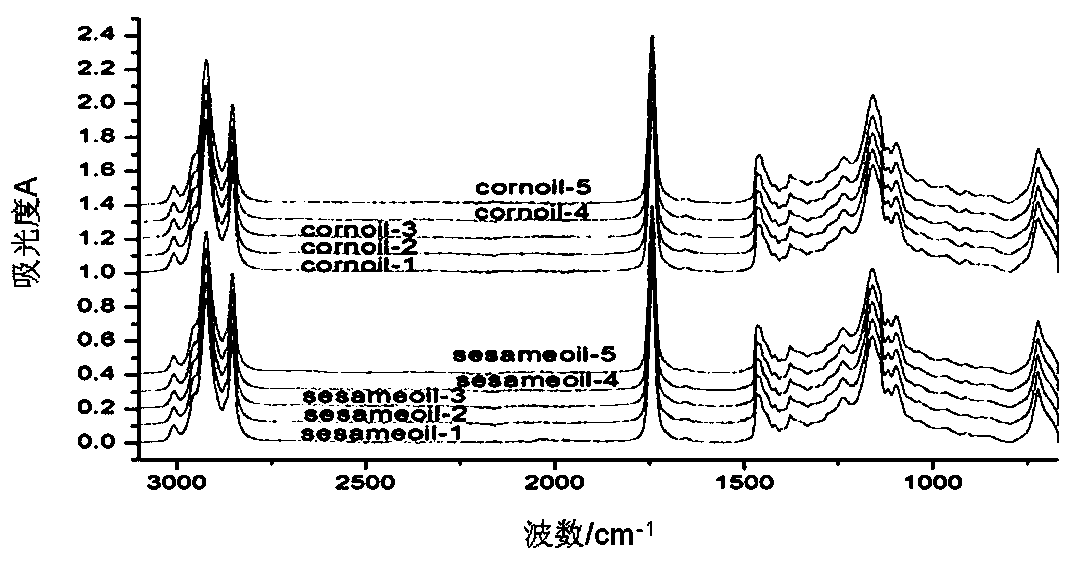

Method used

Image

Examples

Embodiment 1

[0036] A method for extracting vegetable oil unsaponifiable matter, specifically comprising the following steps:

[0037] (1) Add 30mL of 2mol / L potassium hydroxide ethanol solution in 2g vegetable oil sample, vortex and shake for 0.5min, and carry out saponification process to it under ultrasonic heating; Wherein, ethanol in potassium hydroxide ethanol solution is Anhydrous ethanol;

[0038] (2) After the vegetable oil sample is saponified, add deionized water to the treatment solution and shake it up to dilute the saponified solution, then add n-hexane to extract the unsaponifiable matter; wherein, the added deionized water and n-hexane The volume ratio is 7:3, the amount of deionized water added is 35mL, and the amount of n-hexane added is 15mL. After extracting the unsaponifiable matter once, let it stand until the aqueous phase and the organic phase are separated, that is, the extraction of the unsaponifiable matter is completed;

[0039] (3) Design an SPE column special...

Embodiment 2

[0043] A method for extracting vegetable oil unsaponifiable matter, specifically comprising the following steps:

[0044] (1) Add 60mL of 2mol / L potassium hydroxide ethanol solution to 4g vegetable oil sample, vortex and shake for 0.7min, and carry out saponification treatment to it under the effect of ultrasonic heating; wherein, ethanol in potassium hydroxide ethanol solution is Anhydrous ethanol;

[0045] (2) After the vegetable oil sample is saponified, add deionized water to the treatment solution and shake it up to dilute the saponified solution, then add n-hexane to extract the unsaponifiable matter; wherein, the added deionized water and n-hexane The volume ratio is 7:3, the amount of deionized water added is 40mL, and the amount of n-hexane added is 18mL. After extracting the unsaponifiable matter once, let it stand until the aqueous phase and the organic phase are separated, that is, the extraction of the unsaponifiable matter is completed;

[0046] (3) Design an SP...

Embodiment 3

[0050] A method for extracting vegetable oil unsaponifiable matter, specifically comprising the following steps:

[0051] (1) Add 15mL of 2mol / L potassium hydroxide ethanol solution to 1g vegetable oil sample, vortex and shake for 0.6min, and carry out saponification treatment on it under the action of ultrasonic heating; wherein, ethanol in potassium hydroxide ethanol solution Anhydrous ethanol;

[0052] (2) After the vegetable oil sample is saponified, add deionized water to the treatment solution and shake it up to dilute the saponified solution, then add n-hexane to extract the unsaponifiable matter; wherein, the added deionized water and n-hexane The volume ratio is 7:3, the amount of deionized water added is 30mL, and the amount of n-hexane added is 12.8mL. After extracting the unsaponifiable matter once, let it stand until the aqueous phase and the organic phase are separated, that is, the extraction of the unsaponifiable matter is completed;

[0053] (3) Design an SPE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com