Lithium-sulfur battery positive electrode material containing three-dimensional interpenetrating composite carbon material, preparation method, positive electrode sheet containing same, and lithium-sulfur battery

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium batteries, electrode manufacturing, etc., to achieve high utilization and reduce the proportion of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of a lithium-sulfur battery cathode active material, comprising the following steps:

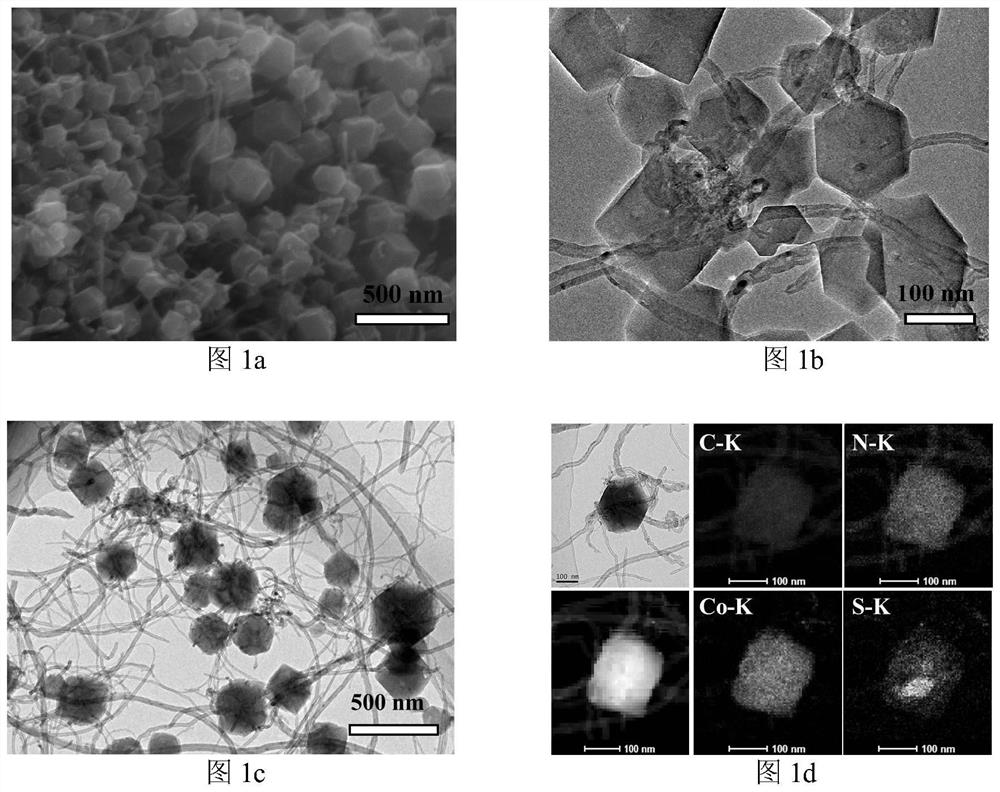

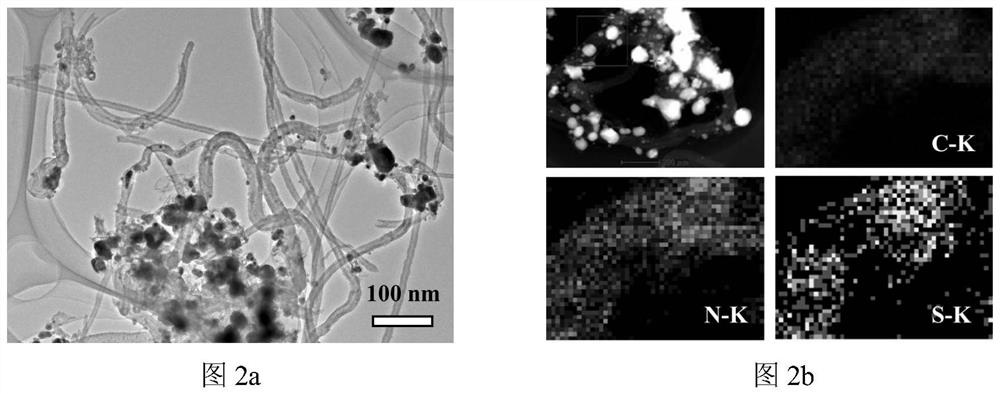

[0048] (1) Using multi-armed carbon nanotubes (after activation treatment) with an average diameter of 20nm as a three-dimensional framework, ZIF-67 was produced in situ on the surface of multi-armed carbon nanotubes to obtain a CNTs / ZIF-67 precursor;

[0049] Take 0.3g of multi-armed carbon nanotubes and evenly disperse them in 100ml of a mixed solution of deionized water and concentrated nitric acid with a volume ratio of 3:1, sonicate until the carbon nanotubes are evenly dispersed, then place them in a constant temperature water bath, and place them under magnetic force at 80°C Stirring treatment for 6 hours, followed by repeated washing with deionized water and absolute ethanol and centrifugation, and drying in a vacuum oven at 60°C for more than 12 hours to obtain activated multi-armed carbon nanotubes;

[0050] Place the above activated carbon nanotubes in ...

Embodiment 2

[0060] A lithium-sulfur battery, the positive electrode active material of the lithium-sulfur battery adopts the positive electrode active material of the lithium-sulfur battery described in Example 1.

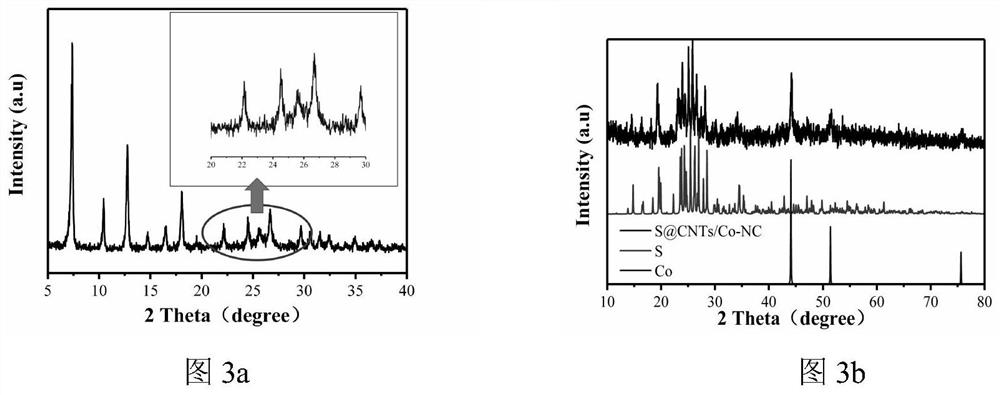

[0061] Please refer to Figure 3 to Figure 4 , the present embodiment provides a lithium-sulfur battery preparation method, comprising the following steps:

[0062] (1) Preparation of positive pole piece. Weigh the lithium-sulfur cathode active material, superconducting carbon, and binder LA133 described in Example 1 according to a mass ratio of 80:10:10 and place them in an agate ball mill jar, and weigh LA133 and deionized water at a mass ratio of 1:30. Take deionized water and add it to the ball mill tank, high-energy ball mill at 400rpm for 30min, then evenly coat the obtained slurry on the aluminum foil, and control the surface density to an average of 1.85mg / cm 2 , put the pole pieces obtained above in a vacuum drying oven, dry them in vacuum at 55°C for 24 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com