Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in light-emitting materials, chemical instruments and methods, nano-optics, etc., can solve the problems of device luminescence quenching and reduce device luminescence performance, achieve simple process, avoid luminescence quenching phenomenon, improve The effect of luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Another aspect of the present invention provides a method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0027] A composite electron transport layer is prepared on the cathode or quantum dot luminescent layer, and the composite electron transport layer contains electron transport materials and ultraviolet absorbing materials.

[0028] A composite electron transport layer is arranged between the cathode in the quantum dot light-emitting diode provided in the embodiment of the present invention and the quantum dot light-emitting layer, and the composite electron transport layer contains an electron transport material and an ultraviolet absorbing material, and the ultraviolet absorbing material can passivate The surface defects of the electron transport material can avoid the luminescence quenching phenomenon of the quantum dot light-emitting diode, thereby improving the luminescence performance of the device.

[0029] Further, the step...

Embodiment 1

[0094] A quantum dot light-emitting diode, the preparation process of which is as follows:

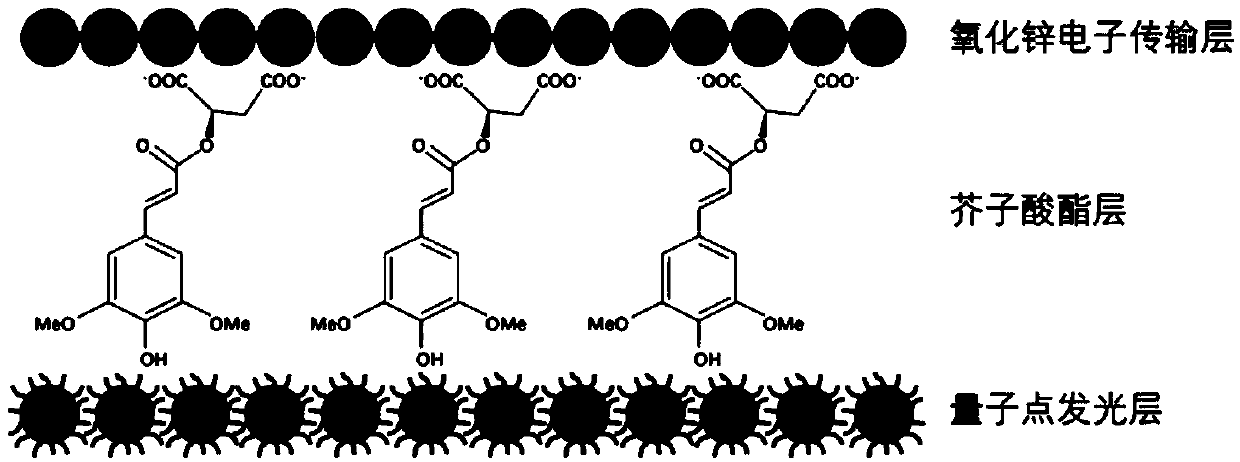

[0095] Firstly, the sinapinyl malic acid is dissolved in methanol at a concentration of 0.2 mmol / L to obtain a sinapinyl malic acid solution, and then the following process steps are carried out.

[0096] A. Spin-coat a PEDOT:PSS layer on the ITO conductive glass;

[0097] B. Spin-coat a layer of TFB on the PEDOT:PSS layer;

[0098] C. Spin-coat a layer of CdSe / ZnS quantum dot luminescent layer on the TFB layer;

[0099] D. Deposit the sinapinyl malic acid solution prepared above on the CdSe / ZnS quantum dot light-emitting layer by spin coating, wherein the spin coating condition is 3000rpm. After the spin coating is completed, heat and anneal the film at 80°C for 30min to obtain sinapinyl Malic acid layer;

[0100] E. Spin-coat one layer of ZnO electron transport layer on the sinapinyl malic acid layer;

[0101] F. Evaporating a layer of Al cathode layer on the ZnO electron transpo...

Embodiment 2

[0103] A quantum dot light-emitting diode, the preparation process of which is as follows:

[0104] Firstly, serapinyl malic acid is dissolved in ethanol at a concentration of 0.5 mmol / L to obtain a serapinyl malic acid solution, and then the following process steps are carried out.

[0105] A. Spin-coat a PEDOT:PSS layer on the ITO conductive glass;

[0106] B. Spin-coat a layer of TFB on the PEDOT:PSS layer;

[0107] C. Spin-coat a layer of CdSe / ZnS quantum dot luminescent layer on the TFB layer;

[0108] D. Spin-coat a ZnO electron transport layer on the CdSe / ZnS quantum dot light-emitting layer;

[0109] E. Deposit the sinapylmalic acid solution prepared above on the ZnO electron transport layer by spin coating, wherein the spin coating condition is 3000rpm. After the spin coating is completed, heat and anneal the film at 80°C for 30min to obtain the sinapinyl malic acid layer ;

[0110] F. Evaporating a layer of Al cathode layer on the sinapylmalic acid layer to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com