Preparation method of ceramic nanofiltration membrane

A technology of ceramic nanofiltration membrane and coating liquid, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of particle shrinkage, prevent grain growth, reduce hydrothermal temperature, and inhibit The effect of crystal aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

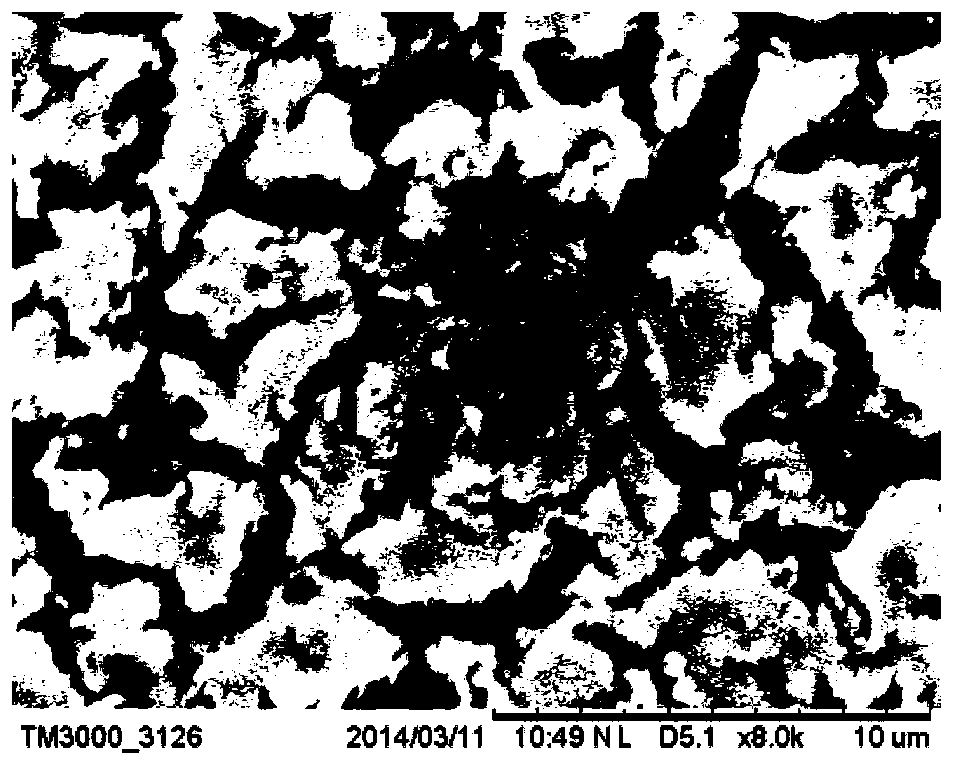

Image

Examples

Embodiment 1

[0034] (1) Add an aqueous solution of nitric acid with a pH of 1.2 to 0.3mol / L n-butyl titanate solution, and stir at room temperature for 20 minutes according to the molar ratio of n-butyl titanate and water at a ratio of 1:50, then drop Add glycerin, the mass ratio of glycerin and n-butyl titanate is 1:1, continue to stir for 30 minutes, and age at 50°C for 12 hours to obtain a transparent titanium oxide sol;

[0035] (2) Add 0.1 mol of mineralizer magnesium oxide and dodecylamine to the titania sol obtained in step (1), and stir evenly, put it into a hydrothermal reaction kettle with a filling degree of 60%, and heat it at 200° C. Under heat preservation reaction for 8h, cooling to prepare a titanium oxide nano solution with uniform particles;

[0036] (3) adding PEG-400 and the hydroxymethylcellulose that molecular weight is 6000-10000 in the titanium oxide nano solution that obtains in step (2), and make the mass concentration of PEG-400 and hydroxymethylcellulose be 5 re...

Embodiment 2

[0039] (1) Add an aqueous solution of nitric acid with a pH of 1 to 0.2mol / L n-butyl titanate solution, and stir at room temperature for 20 minutes according to the molar ratio of n-butyl titanate and water at a ratio of 1:10, then drop Add glycerin, the mass ratio of glycerin and n-butyl titanate is 1:1, continue to stir for 30 minutes, and age at 50°C for 12 hours to obtain a transparent titanium oxide sol;

[0040] (2) Add 0.1mol mineralizer sodium fluoride and dodecylamine to the titania sol obtained in step (1), and stir evenly, put it into a hydrothermal reaction kettle, the filling degree is 50%, and at 120 Keeping the reaction at ℃ for 5 hours, cooling to prepare a titanium oxide nano-solution with uniform particles;

[0041] (3) adding PEG-400 and the hydroxymethylcellulose that molecular weight is 6000-10000 in the titanium oxide nanometer solution that obtains in step (2), and make the mass concentration of PEG-400 and hydroxymethylcellulose be 2 respectively %, 0....

Embodiment 3

[0044] (1) Add nitric acid aqueous solution with a pH of 1.5 to 0.5 mol / L n-butyl titanate solution, and stir at room temperature for 20 minutes according to the molar ratio of n-butyl titanate and water at a ratio of 1:100, then drop Add glycerin, the mass ratio of glycerin and n-butyl titanate is 1:2, continue to stir for 30 minutes, and age at 50°C for 12 hours to obtain a transparent titanium oxide sol;

[0045] (2) Add 0.1 mol of mineralizer ammonium nitrate and dodecylamine to the titanium oxide sol obtained in step (1), and stir evenly, put it into a hydrothermal reaction kettle with a filling degree of 80%, and heat it at 120° C. Reaction at lower temperature for 10 hours, cooling to obtain a titanium oxide nano-solution with uniform particles;

[0046] (3) adding PEG-400 and molecular weight to the hydroxypropyl cellulose of 6000-10000 in the titanium oxide nanometer solution that obtains in step (2), and make the mass concentration of PEG-400 and hydroxypropyl cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com