Magnetic composite adsorption material based on Fe3O4-Co-based MOFs, and preparation method of magnetic composite adsorption material

A composite adsorption material, fe3o4-co technology, applied in adsorption water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., which can solve problems such as difficulty in recycling adsorption materials and secondary pollution , to avoid secondary pollution, reduce adsorption costs, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Co-based MOFs material preparation method comprises the following steps:

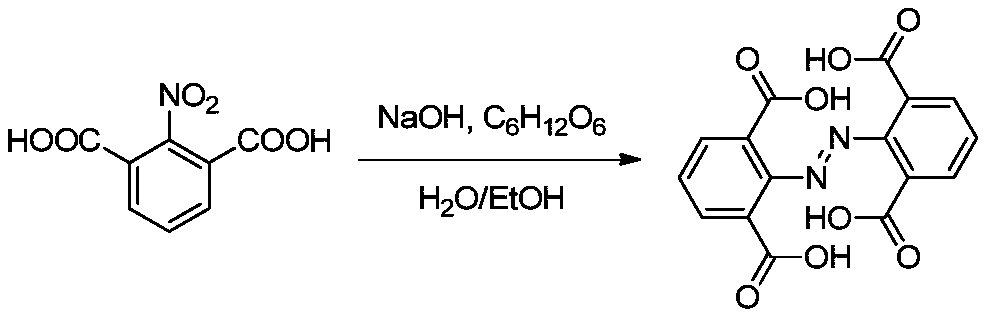

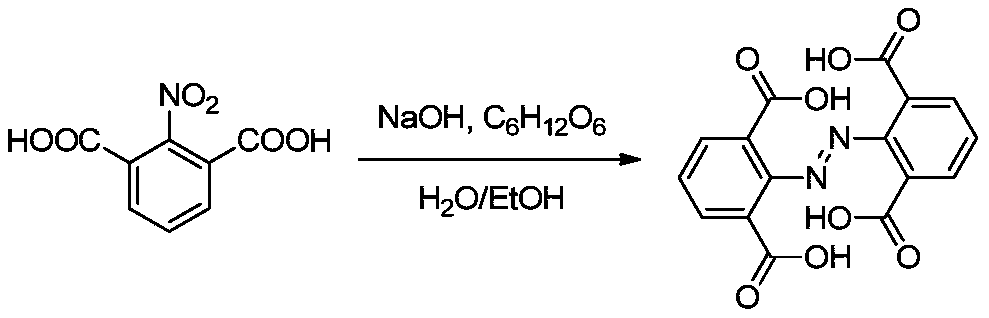

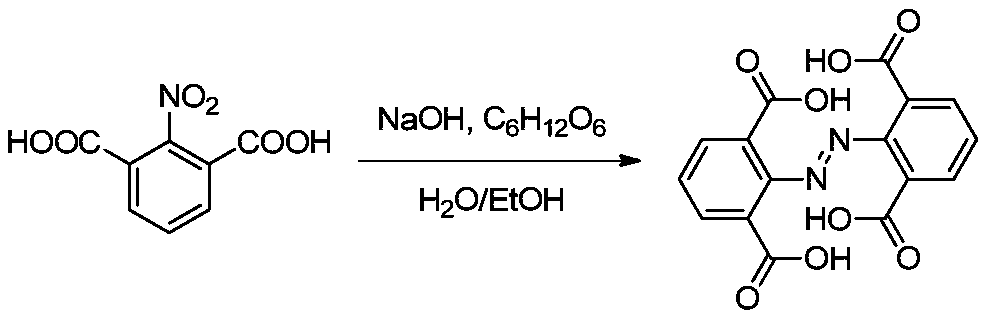

[0027] (1) Add an appropriate amount of absolute ethanol to the reaction flask, add 2-nitroisophthalic acid and stir to dissolve, add an appropriate amount of distilled water and sodium hydroxide, the volume ratio of absolute ethanol and distilled water is 1:1.5-2, and The reaction bottle was placed in a constant temperature water bath and heated to 70-80°C, refluxed for 2-4h, then added glucose (C 6 h 12 o 6 ), the mass ratio of 2-nitroisophthalic acid, sodium hydroxide and glucose is 1:2-2.5:5-6, the reaction temperature is reduced to 40-50°C, the reaction is stirred at a constant speed for 20-25h, and the reaction is passed by TLC The reaction process was observed by thin-layer chromatography. After the reaction of 2-nitroisophthalic acid was complete, hydrochloric acid solution was added dropwise to the reaction flask, the pH of the solution was adjusted to 4-5, and the mixture was stirred ...

Embodiment 1

[0034] (1) Preparation of organic ligand 2,2',6,6'-azobenzene tetracarboxylate compound 1: add an appropriate amount of absolute ethanol to the reaction flask, add 2-nitroisophthalic acid and stir to dissolve, add an appropriate amount of distilled water and sodium hydroxide, absolute ethanol and distilled water volume ratio is 1:1.5, the reaction bottle is placed in a constant temperature water bath and heated to 70 ° C, reflux reaction 2h, then add glucose (C 6 h 12 o 6 ), the mass ratio of 2-nitroisophthalic acid, sodium hydroxide and glucose is 1:2:5, the reaction temperature is down to 40°C, and the reaction is stirred at a constant speed for 20h, and the reaction is observed by TLC thin layer chromatography. , when the reaction of 2-nitroisophthalic acid is complete, add hydrochloric acid solution dropwise to the reaction flask, adjust the pH of the solution to 5, stir at a constant speed for 2 hours, add an appropriate amount of distilled water and ethyl acetate to the...

Embodiment 2

[0039] (1) Preparation of organic ligand 2,2',6,6'-azobenzene tetracarboxylate compound 2: add an appropriate amount of absolute ethanol to the reaction flask, add 2-nitroisophthalic acid and stir to dissolve, add an appropriate amount of Distilled water and sodium hydroxide, the volume ratio of absolute ethanol and distilled water is 1:1.6, the reaction bottle is placed in a constant temperature water bath and heated to 70 ° C, reflux for 3 hours, then add glucose (C 6 h 12 o 6 ), the mass ratio of 2-nitroisophthalic acid, sodium hydroxide and glucose is 1:2:5, the reaction temperature is down to 40°C, and the reaction is stirred at a constant speed for 20h, and the reaction is observed by TLC thin layer chromatography. , when the reaction of 2-nitroisophthalic acid is complete, add hydrochloric acid solution dropwise to the reaction flask, adjust the pH of the solution to 4, stir at a constant speed for 2 hours, add an appropriate amount of distilled water and ethyl acetate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com