Elastic aluminium-plastic film used for flexible package of lithium battery and production method

An aluminum-plastic film and flexible packaging technology, which is applied in the field of elastic aluminum-plastic film for lithium battery flexible packaging and its preparation, can solve problems such as affecting the safety and service life of lithium batteries, micro-cracks in the aluminum foil layer, and easy corrosion of the outer layer of the aluminum-plastic film. , to achieve the effect of improving safety and service life, improving corrosion resistance and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add the heat-resistant resin and the first bonding material into the screw extruder, and form a film by co-extrusion casting to obtain the outer protective layer of the nylon cast film; the heat-resistant resin is nylon 6; the first bonding The material is epoxy resin; the addition of the first bonding material is 10% of the mass of the heat-resistant resin;

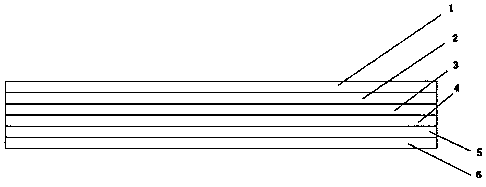

[0035] (2) As attached figure 1 As shown, the nylon cast film outer protective layer 1, the fluororubber microporous foam layer 2, the first adhesive layer 3, the aluminum foil layer 4, the PP coating layer 5, and the CPP film heat sealing layer are arranged in order from outside to inside The order of 6 is stacked and compounded, and the layers are bonded by adhesive to obtain an elastic aluminum-plastic film for lithium battery flexible packaging; the fluororubber is fluororubber 26; the fluororubber microporous foam layer contains zinc oxide; the addition of zinc oxide The amount is 3% of the mass of fluor...

Embodiment 2

[0039] (1) Add the heat-resistant resin and the first bonding material into the screw extruder, and form a film by co-extrusion casting to obtain the outer protective layer of the nylon cast film; the heat-resistant resin is nylon 12; the first bonding The material is silicone resin; the addition of the first bonding material is 5% of the mass of the heat-resistant resin;

[0040] (2) Set up the outer protective layer 1 of the nylon cast film, the microporous foam layer 2 of the fluorine rubber, the first adhesive layer 3, the aluminum foil layer 4, the PP coating layer 5, and the heat sealing layer of the CPP film in sequence from the outside to the inside The sequence of 6 is stacked and compounded, and the layers are bonded by adhesive to obtain an elastic aluminum-plastic film for lithium battery flexible packaging; the fluororubber is perfluoroether rubber; the microporous foam layer of the fluororubber contains alumina; the aluminum oxide The amount added is 4% of the ma...

Embodiment 3

[0044] (1) Add the heat-resistant resin and the first bonding material into the screw extruder, and form a film by co-extrusion casting to obtain the outer protective layer of the nylon cast film; the heat-resistant resin is nylon 1010; the first bonding The material is epoxy resin; the addition of the first bonding material is 15% of the mass of the heat-resistant resin;

[0045] (2) Set up the outer protective layer 1 of the nylon cast film, the microporous foam layer 2 of the fluorine rubber, the first adhesive layer 3, the aluminum foil layer 4, the PP coating layer 5, and the heat sealing layer of the CPP film in sequence from the outside to the inside The order of 6 is stacked and compounded, and the layers are bonded by adhesive to obtain an elastic aluminum-plastic film for lithium battery flexible packaging; the fluororubber is tetrapropylene fluororubber; the fluororubber microporous foam layer contains magnesium oxide; the magnesium oxide The amount added is 5% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com