A converter steelmaking method for producing low-sulfur and phosphorous-containing IF steel by rh single process

A converter steelmaking and process technology, applied in the field of steelmaking, can solve the problems of mismatching casting cycle of casting machines, lack of desulfurization conditions, lack of temperature adjustment means, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Heat number: 191354500, steel grade: SR250P1, total charge: 241t.

[0056] 1. Conditions of molten iron and steel scrap in the furnace

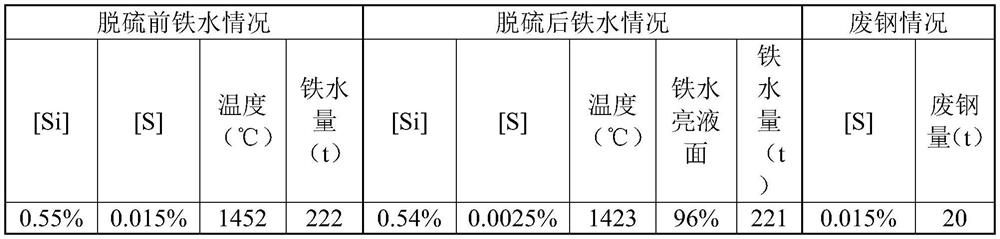

[0057] Table 1 Situation of molten iron and steel scrap in the furnace

[0058]

[0059] 2. Addition of slag making material

[0060] The amount of lime added: 11.2t, the amount of lightly burned dolomite added: 4.8t. Basicity of final slag of converter: 3.35, MgO content of final slag of converter: 10.3%.

[0061] 3. End point control of converter

[0062] End point oxygen content: 1002ppm, end point sulfur content: 0.0028%, end point temperature: 1738°C.

[0063] 4. Alloy addition during converter tapping

[0064] The amount of ferromanganese added: 3606kg, the amount of ferrophosphorus added: 586kg.

[0065] 5. Molten steel situation at the RH station

[0066] Oxygen content of molten steel at the arrival station: 480ppm, arrival temperature: 1648°C.

[0067] 6. RH treatment

[0068] The RH treatment time is 36 minutes; ...

Embodiment 2

[0070] Heat number: 192423600, steel grade: SR250P1, total charge: 245t.

[0071] 1. Conditions of molten iron and steel scrap in the furnace

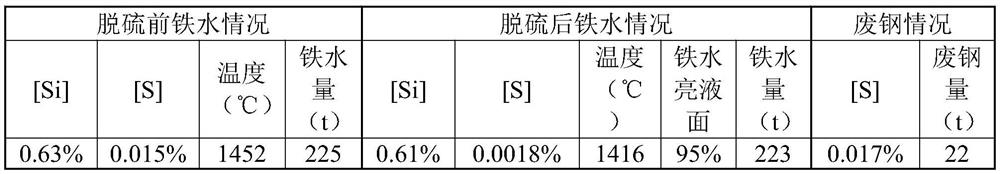

[0072] Table 2 Situation of molten iron and steel scrap in the furnace

[0073]

[0074] 2. Addition of slag making material

[0075] The amount of lime added: 12.8t, the amount of lightly burned dolomite added: 5.2t. Basicity of final slag of converter: 3.40, MgO content of final slag of converter: 10.5%.

[0076] 3. End point control of converter

[0077] End point oxygen content: 1142ppm, end point sulfur content: 0.0040%, end point temperature: 1745°C.

[0078] 4. Alloy addition during converter tapping

[0079] The amount of ferromanganese added: 3880kg, the amount of ferrophosphorus added: 610kg.

[0080] 5. Molten steel situation at the RH station

[0081] Oxygen content of molten steel at the arrival station: 465ppm, arrival temperature: 1651°C.

[0082] 6. RH treatment

[0083] The RH treatment time is 35 minutes; ...

Embodiment 3

[0085] Heat number: 191354600, steel grade: SR250P1, total charge: 245t.

[0086] 1. Conditions of molten iron and steel scrap in the furnace

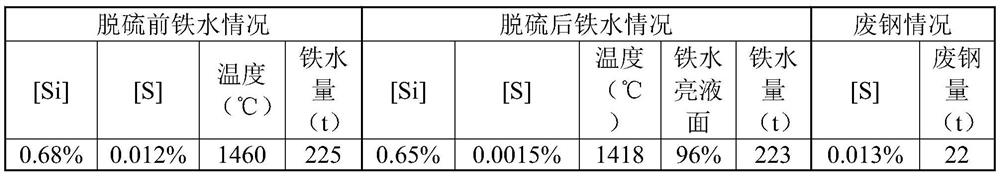

[0087] Table 3 Situation of molten iron and steel scrap in the furnace

[0088]

[0089] 2. Addition of slag making material

[0090] The amount of lime added: 13.4t, the amount of lightly burned dolomite added: 5.7t. Basicity of final slag of converter: 3.38, MgO content of final slag of converter: 10.4%.

[0091] 3. End point control of converter

[0092] End point oxygen content: 978ppm, end point sulfur content: 0.0028%, end point temperature: 1742°C.

[0093] 4. Alloy addition during converter tapping

[0094] The amount of ferromanganese added: 3510kg, the amount of ferrophosphorus added: 580kg.

[0095] 5. Molten steel situation at the RH station

[0096] Oxygen content of molten steel at the arrival station: 426ppm, arrival temperature: 1643°C.

[0097] 6. RH treatment

[0098] The RH treatment time is 37 minutes; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com