Chromium-doped strontium aluminum niobate tunable laser crystal as well as preparation method and application thereof

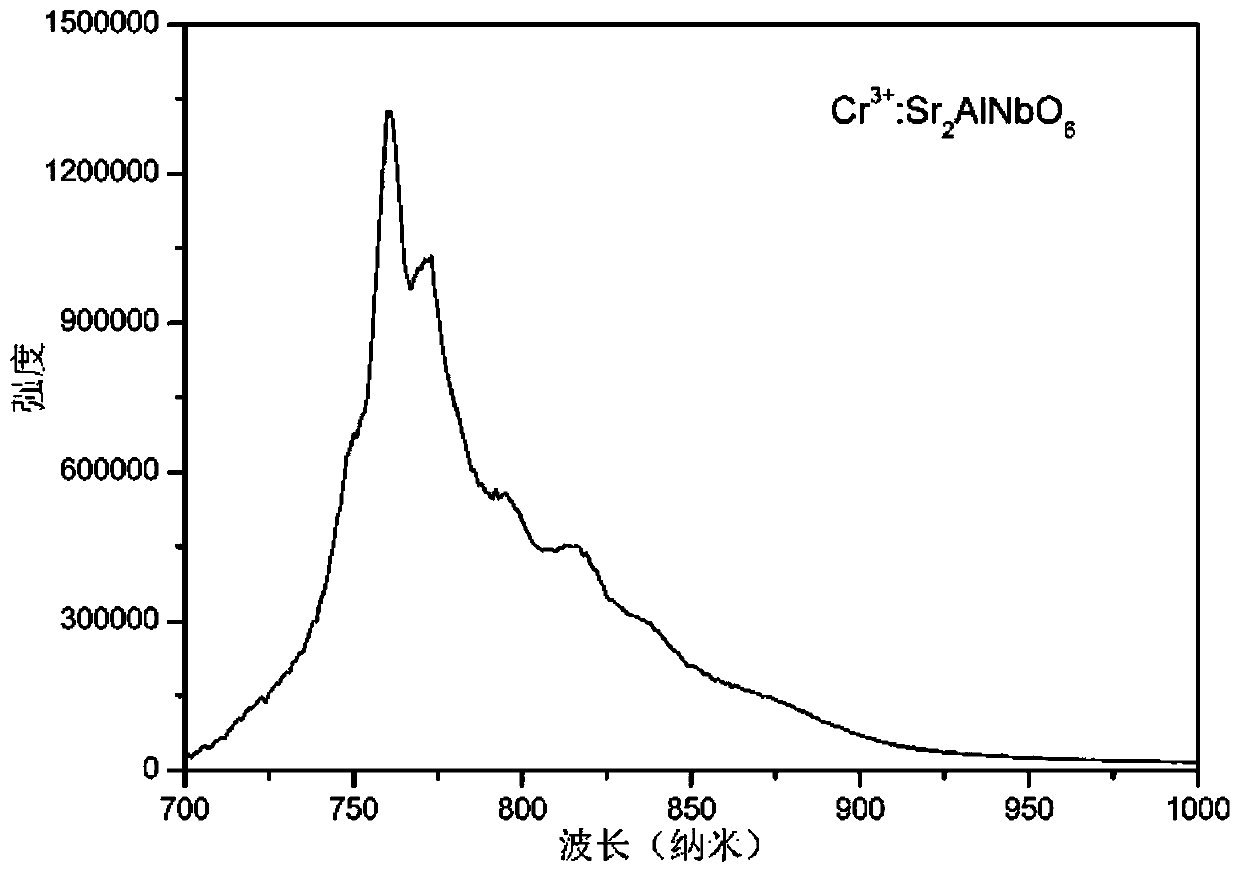

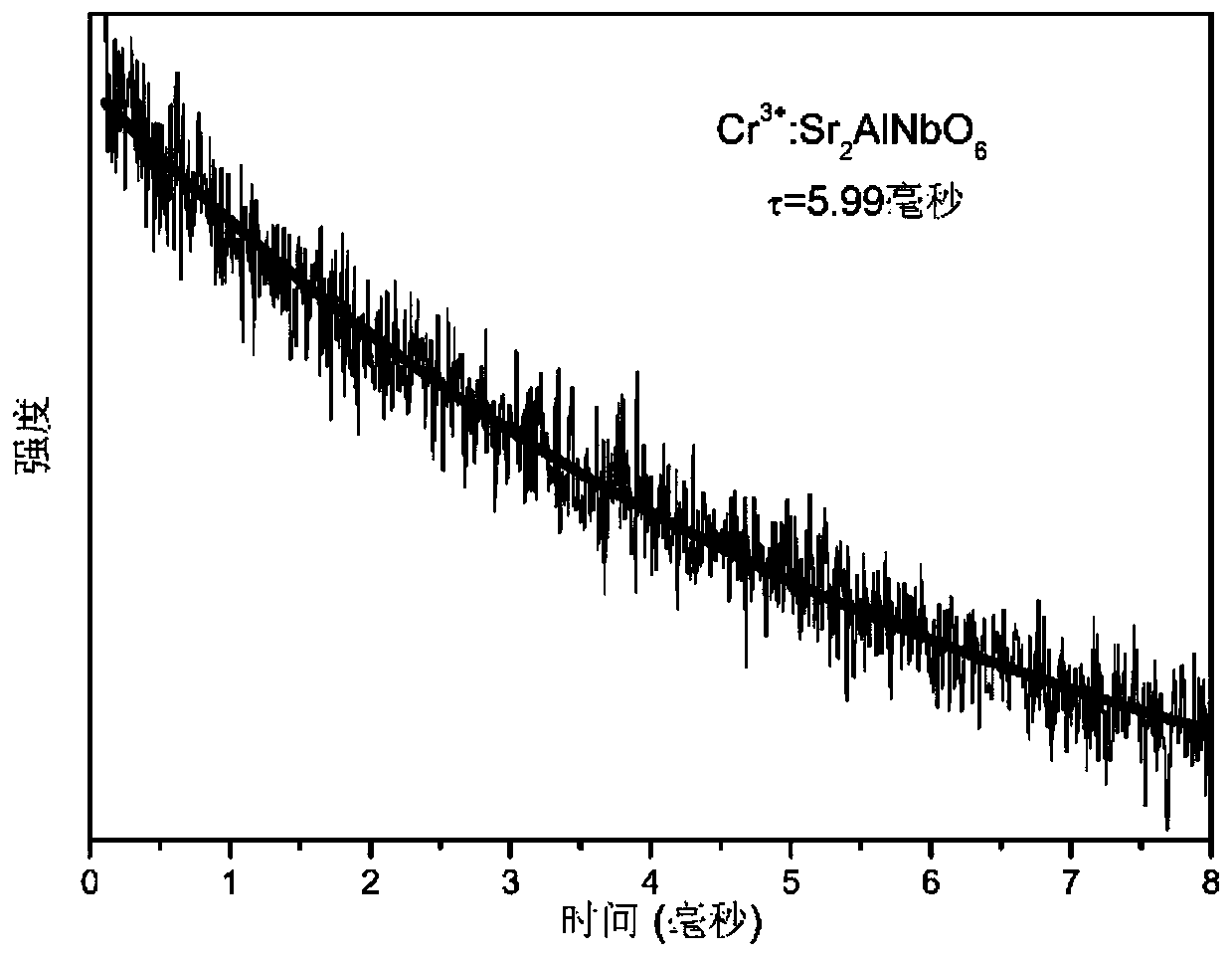

A laser crystal, chromium doping technology, applied in lasers, crystal growth, laser parts and other directions, can solve the problems of poor wavelength range, insufficient absorption coefficient and low quantum efficiency of tunable laser crystals, and achieve a mature and stable growth process. , the effect of high emission intensity and simple preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

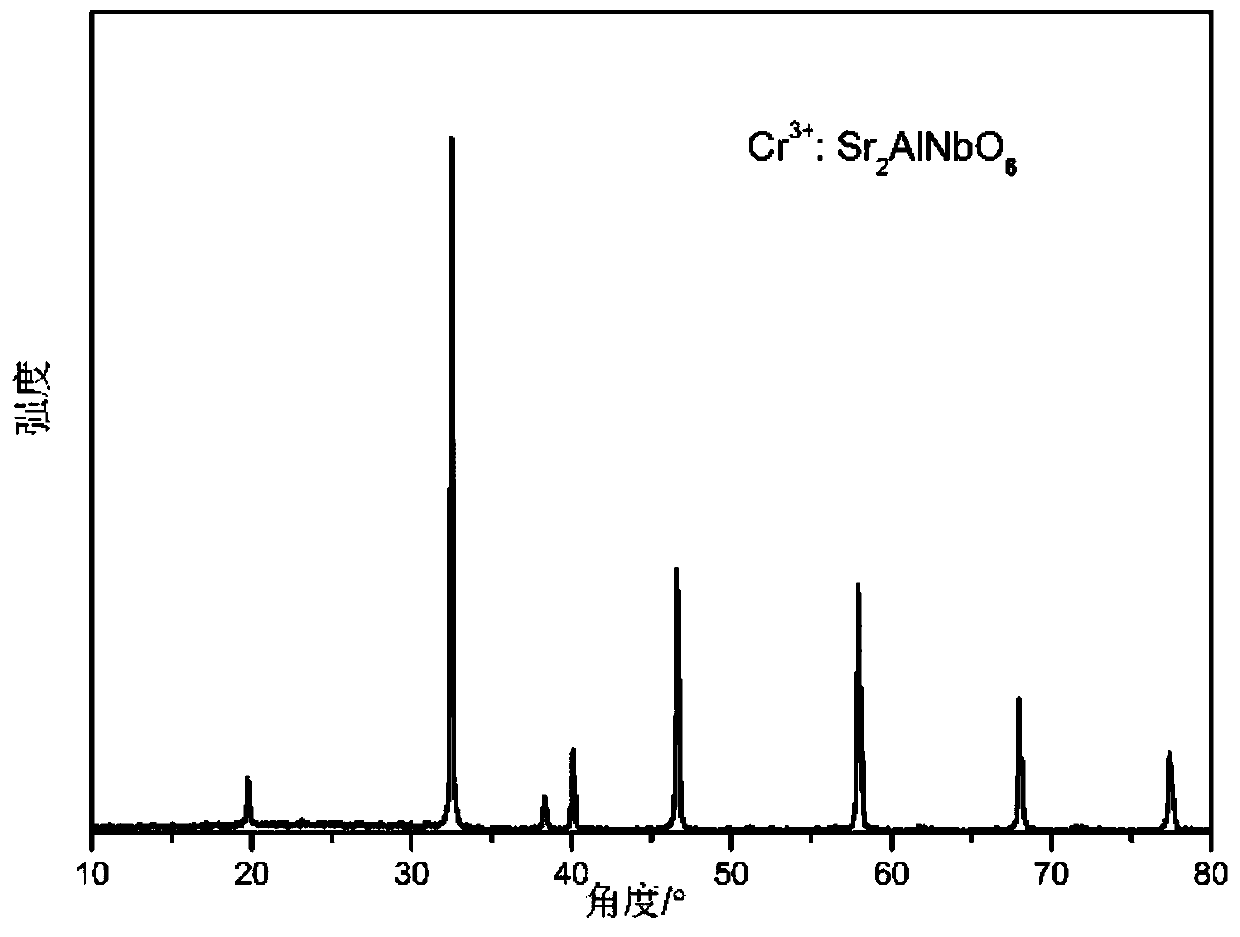

[0025] This embodiment provides a method for preparing a chromium-doped aluminum strontium niobate tunable laser crystal, and the specific steps are as follows:

[0026] Step 1: Obtain Cr by high-temperature solid-phase method 3+ :Sr 2 AlNbO 6 (Cr 3+ The doping concentration is 0.2at.%) Raw material: the initial raw material is Al 2 o 3 , SrCO 3 , Nb 2 o 5 and Cr 2 o 3 , use the metering ratio of the following chemical equation to weigh the materials; use an agate mortar to grind and mix the initial raw materials evenly, then put them into a 50×50mm corundum crucible, place them in a muffle furnace, and heat up to 800°C for pre-sintering. Keep it warm for 8 hours, take it out, grind it again evenly, and heat it for 16 hours at 1550°C for the second sintering, and finally get Cr 3+ :Sr 2 AlNbO 6 raw material;

[0027] 4SrCO 3 +Nb 2 o 5 +0.002Cr 2 o 3 +0.998Al 2 o 3 →2Sr 2 al 0.998 Cr 0.002 NbO 6 +4CO 2 ↑

[0028] Step 2: Grind the synthesized raw mater...

Embodiment 2

[0031] This embodiment provides a method for preparing a chromium-doped aluminum strontium niobate tunable laser crystal, and the specific steps are as follows:

[0032] Step 1: Obtain Cr by high-temperature solid-phase method 3+ :Sr 2 AlNbO 6 (Cr 3+ The doping concentration is 1.5at.%) raw material, the initial raw material is Al 2 o 3 , SrCO 3 , Nb 2 o 5 and Cr 2 o 3 , use the metering ratio of the following chemical formula to weigh the materials, use an agate mortar to grind and mix the initial raw materials evenly, then put them into a 50×50mm corundum crucible, place them in a muffle furnace, and heat up to 900°C for pre-sintering. Keep it warm for 8 hours, take it out, grind it again evenly, and heat it for 19 hours at 1550°C for the second sintering, and finally get Cr 3+ :Sr 2 AlNbO 6 raw material;

[0033] 4SrCO 3 +Nb 2 o 5 +0.015Cr 2 o 3 +0.985Al 2 o 3 →2Sr 2 al 0.985 Cr 0.015 NbO 6 +4CO 2 ↑

[0034] Step 2: Grind the synthesized raw materi...

Embodiment 3

[0036] This embodiment provides a method for preparing a chromium-doped aluminum strontium niobate tunable laser crystal, and the specific steps are as follows:

[0037] Step 1: Obtain Cr by high-temperature solid-phase method 3+ :Sr 2 AlNbO 6 (Cr 3+ The doping concentration is 5.0at.%) raw material, the initial raw material is Al 2 o 3 , SrCO 3 , Nb 2 o 5 and Cr 2 o 3 , use the metering ratio of the following chemical equation to weigh the materials, use an agate mortar to grind and mix the initial raw materials evenly, then put them into a 50×50mm corundum crucible, place them in a muffle furnace, and heat up to 1000°C for pre-sintering. Keep it warm for 8 hours, take it out, grind it again evenly, and heat it for 24 hours at 1550°C for the second sintering, and finally get Cr 3+ :Sr 2 AlNbO 6 raw material;

[0038] 4SrCO 3 +Nb 2 o 5 +0.05Cr 2 o 3 +0.95Al 2 o 3 →2Sr 2 al 0.95 Cr 0.05 NbO 6 +4CO 2 ↑

[0039] Step 2: Grind the synthesized raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com