Method for growing gallium nitride film on silicon substrate

A gallium nitride and silicon substrate technology, applied in electrical components, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve problems such as large differences in lattice constant and thermal expansion coefficient, large tensile stress, cracks, etc., to prevent The effect of melting back etching reaction, eliminating surface cracks and alleviating lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described more fully below using examples. This invention may be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein.

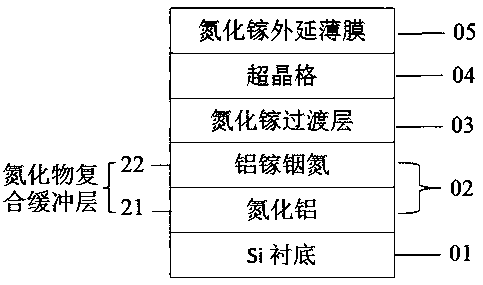

[0023] Such as figure 1 As shown, the present invention provides a method for growing a GaN epitaxial film material without cracks on the surface on a Si substrate, and the structure in the figure is prepared by the following steps:

[0024] Step 1: Select a piece of single crystal Si as the substrate;

[0025] Step 2: epitaxially growing a nitride composite buffer layer on the Si substrate, the nitride composite buffer layer can relieve the lattice mismatch and prevent the remelting etching reaction;

[0026] Step 3: growing a GaN transition layer on the nitride composite buffer layer;

[0027] Step 4: grow a set of superlattice on the GaN transition layer, the superlattice can release part of the tensile stress and filter part of the threading dislocati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com