Ester resin, antiplasticizer, cellulose ester resin composition, optical film and liquid crystal display device

A technology of optical film and ester resin, which is applied in the fields of optics, nonlinear optics, organic chemistry, etc., can solve the problems of film strength and moisture permeability resistance, etc., and achieve an increase in elastic modulus, excellent strength and moisture permeability resistance, and a balance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

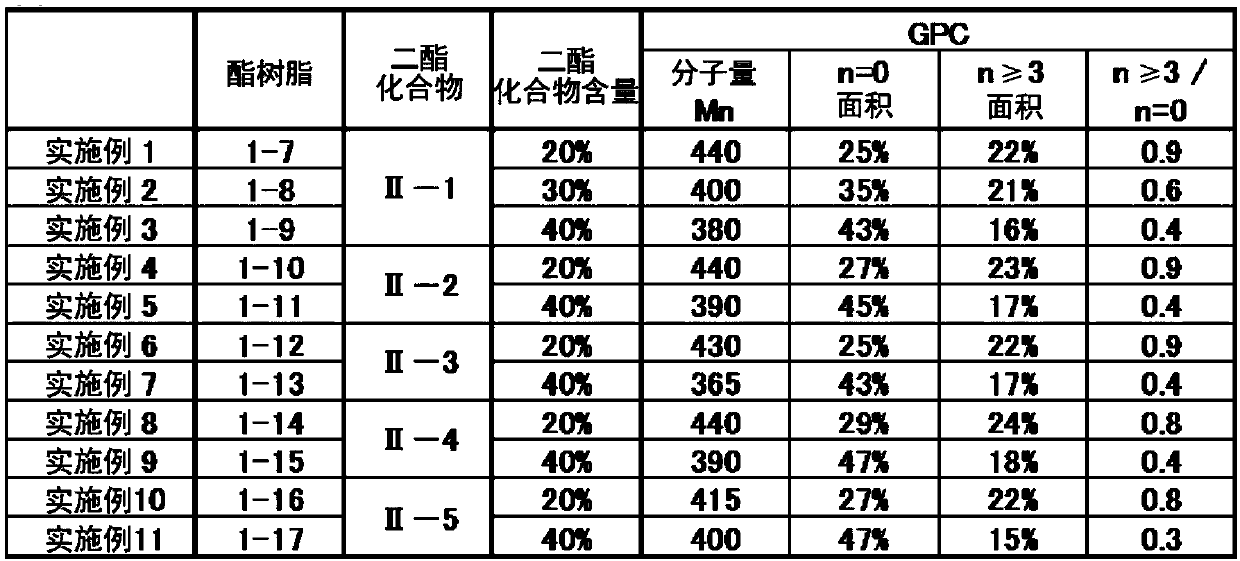

[0121] Hereinafter, based on an Example, this invention is demonstrated more concretely. Parts and % in examples are based on mass unless otherwise specified.

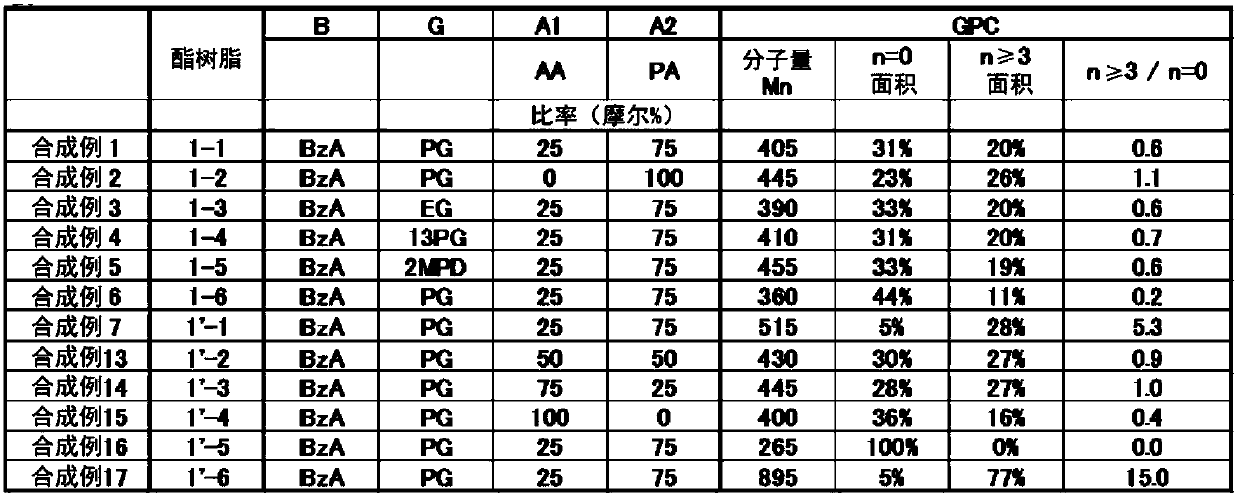

Synthetic example 1

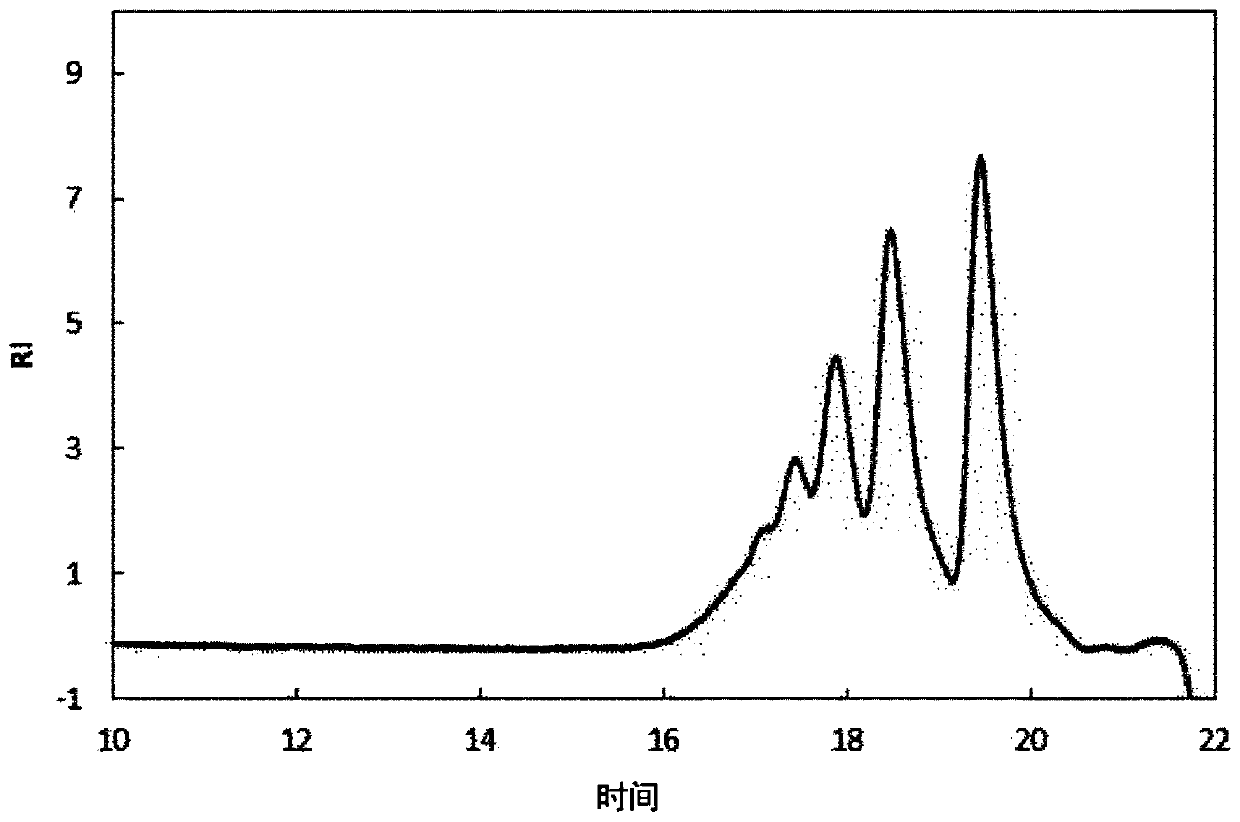

[0123] 405 g of 1,2-propanediol (PG) as a diol component, 79 g of adipic acid (AA) as a dicarboxylic acid, 240 g of phthalic anhydride (PA), and 586 g of benzoic acid (BzA) as a monocarboxylic acid Put 0.08 g of tetraisopropyl titanate (TIPT) as an esterification catalyst into a four-necked flask with an internal volume of 2 liters equipped with a thermometer, a stirrer, and a reflux condenser, and stir under a nitrogen stream while gradually The temperature was raised to 230° C., and then the reaction was continued at 230° C., and a dehydration condensation reaction occurred for a total of 19 hours to obtain a reaction product (acid value: 0.22, hydroxyl value: 16). The number average molecular weight (Mn) of the ester resin (1-1) which is the reaction product thereof was 405. figure 1 A spectrum obtained by GPC measurement is shown. In the GPC spectrum, the area % of components with n=0 was 31%, and the area % of components with n being 3 or more was 20%.

Synthetic example 2

[0125] Using 405 g of PG as a diol component, 320 g of PA as a dicarboxylic acid component, 586 g of BzA as a monocarboxylic acid component, and 0.08 g of TIPT, it synthesized similarly to the synthesis example 1, and obtained ester resin (1-2). Its properties are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com