Sand-coating-sand base paint and preparation method, sand-coating-sand colorful paint and floor coating containing sand-coating-sand base paint

A basic paint and multi-color paint technology, applied in sand-coated sand multi-color paint and floor coatings, sand-coated sand basic paint and preparation fields, can solve the problems of floor paint color, single effect, etc., to achieve outstanding concave-convex effect and simulation degree , high hardness, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

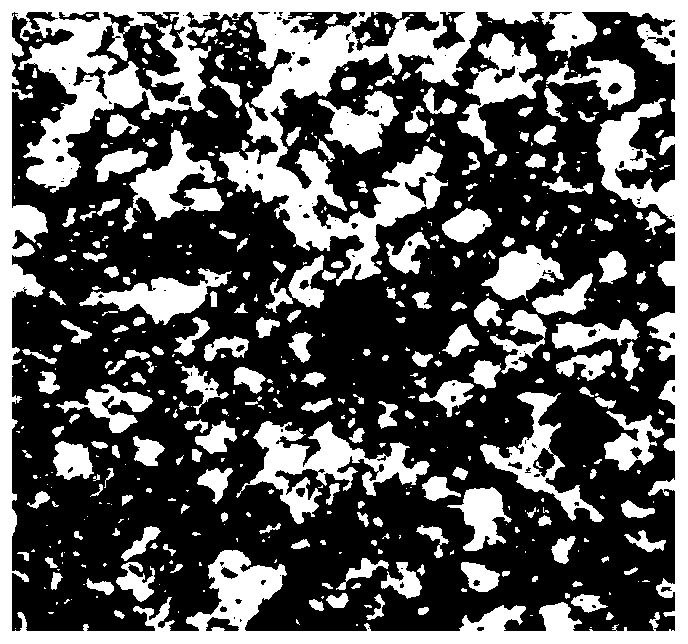

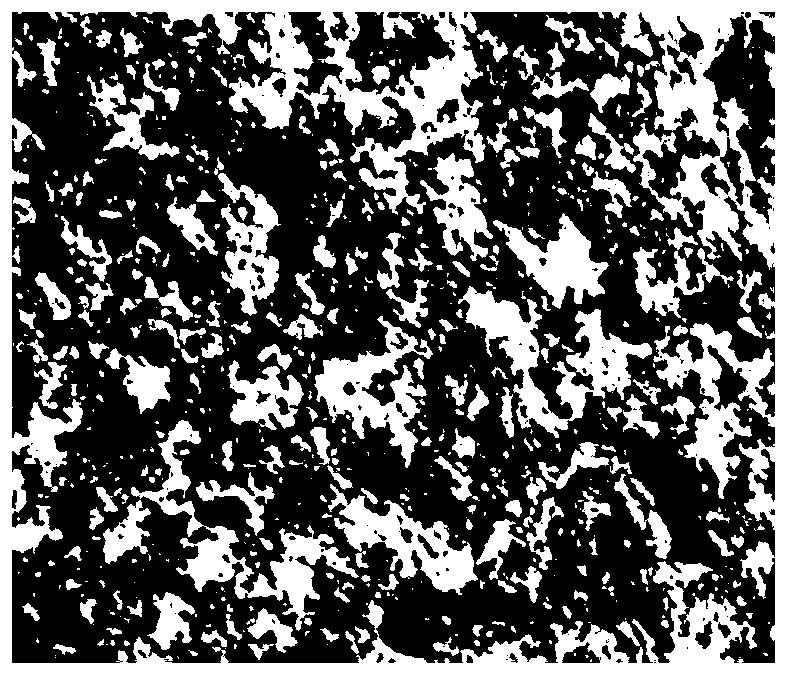

Image

Examples

preparation example 1

[0102] A sand-in-sand colorful paint, the preparation method is as follows:

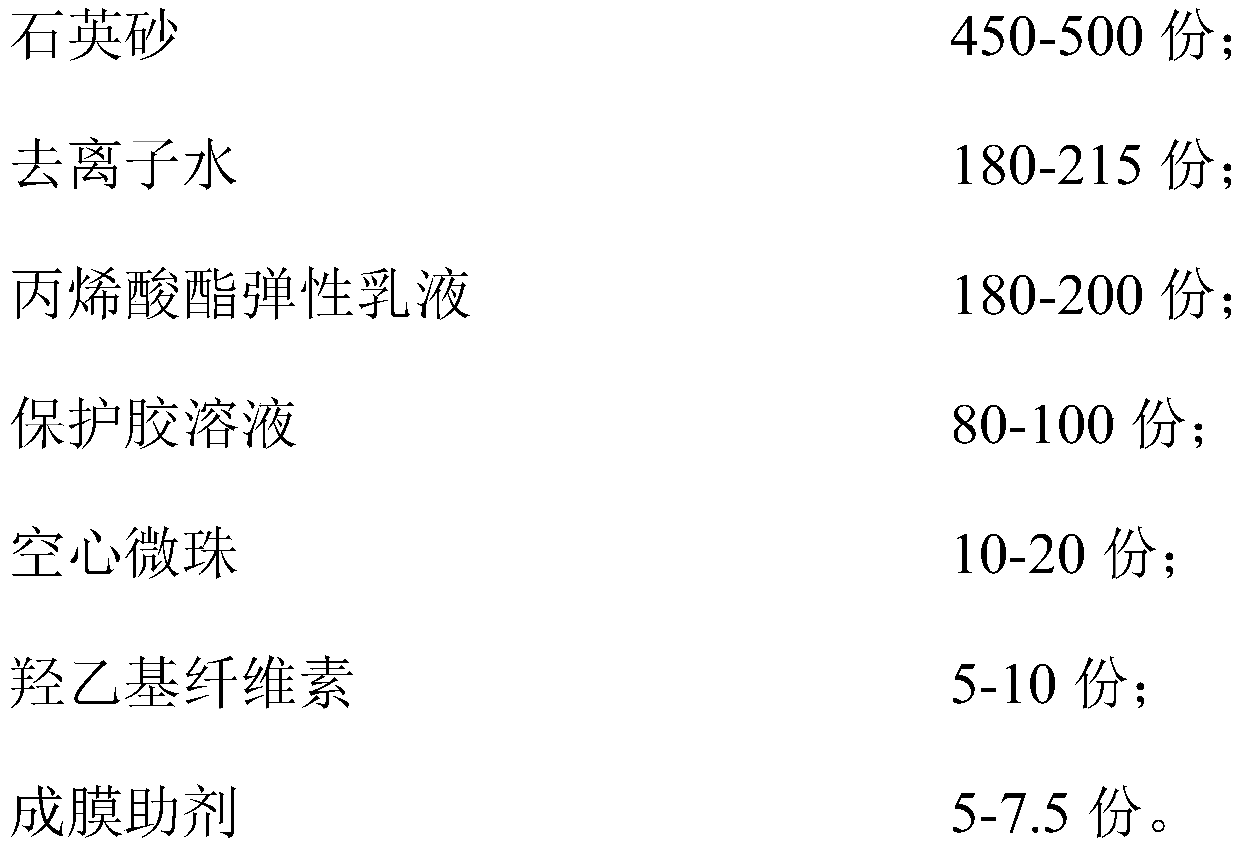

[0103] (1) Preparation of sand-in-sand base paint

[0104] Be 1000 parts by total weight, get 215 parts of deionized water, 7.5 parts of hydroxyethyl cellulose, 1.5 parts of multifunctional neutralizing aids, 7 parts of dispersants, 1.5 parts of preservatives, 10 parts of antifreeze, 20 parts of Parts of hollow microspheres, 10 parts of titanium dioxide, 181 parts of elastic acrylic emulsion, 5 parts of film-forming aids, 1.5 parts of penetrating wetting agent, 80 parts of protective colloid solution, 5 parts of defoamer and 450 parts of 80-120 mesh quartz Sand: Mix and disperse the above raw materials sequentially under 800r / min stirring speed.

[0105] (2) Preparation of protective colloid solution

[0106] According to the total weight of the protective colloid solution as 1000 parts, 930 parts of water are added to the dispersion tank, while stirring, 4 parts of xanthan gum are added to the dis...

preparation example 2-5

[0112]The difference with Preparation Example 1 is that the 80-120 mesh quartz sand is replaced by 40-80 mesh quartz sand (preparation example 2), 120-180 mesh quartz sand (preparation example 3), 20-40 mesh quartz sand (preparation example 4), 180-220 mesh quartz sand (preparation example 5).

preparation example 6

[0114] A sand-in-sand colorful paint, the preparation method is as follows:

[0115] (1) Preparation of sand-in-sand base paint

[0116] Parts by total weight are 1000 parts, get 179.5 parts of deionized water, 10 parts of hydroxyethyl cellulose, 1.5 parts of multifunctional neutralizing aids, 5 parts of dispersants, 1.5 parts of preservatives, 20 parts of antifreeze, 15 parts of Parts of hollow microspheres, 25 parts of titanium dioxide, 200 parts of acrylic elastic emulsion, 6 parts of film-forming aids, 1.5 parts of penetrating wetting agent, 80 parts of protective colloid solution, 5 parts of defoaming agent and 450 parts of 40-80 mesh quartz Sand: Mix and disperse the above raw materials sequentially under 800r / min stirring speed.

[0117] (2) Preparation of protective colloid solution

[0118] According to the total weight of the protective colloid solution as 1000 parts, 930 parts of water are added to the dispersion tank, while stirring, 4 parts of xanthan gum are ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com