Sealing filler of cavity between coke oven protective plate and oven door frame

A slurry and inorganic composite technology, which is used in the door/closure of coke oven, coke oven, heating of coke oven, etc., can solve the problems of high price, low solid residual rate, easy hardening and cracking, etc., and reduce smoke emission. and fugitive emissions, improve the coke oven environment, and improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

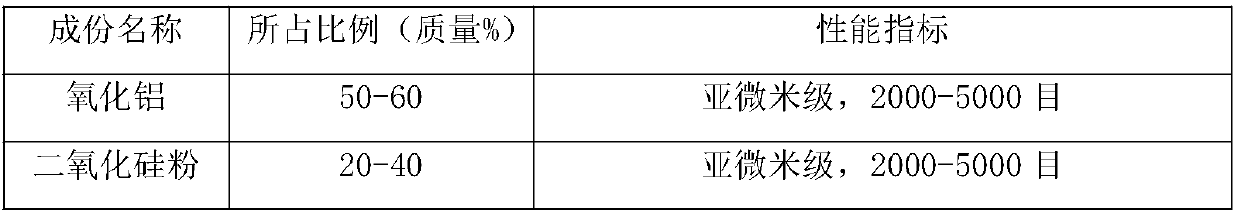

[0033] The formula selection of embodiment 1 inorganic-inorganic composite slurry

[0034] (1) Selection of base material

[0035] Because the materials involved in the invention are applied to the cavity environment between the coke oven protection plate and the furnace door frame, the selected base material needs to have good fluidity and dispersion, stable chemical properties, not easy to react, and resistant to high temperature and burning , so the present invention chooses nano-scale silica sol as the matrix material.

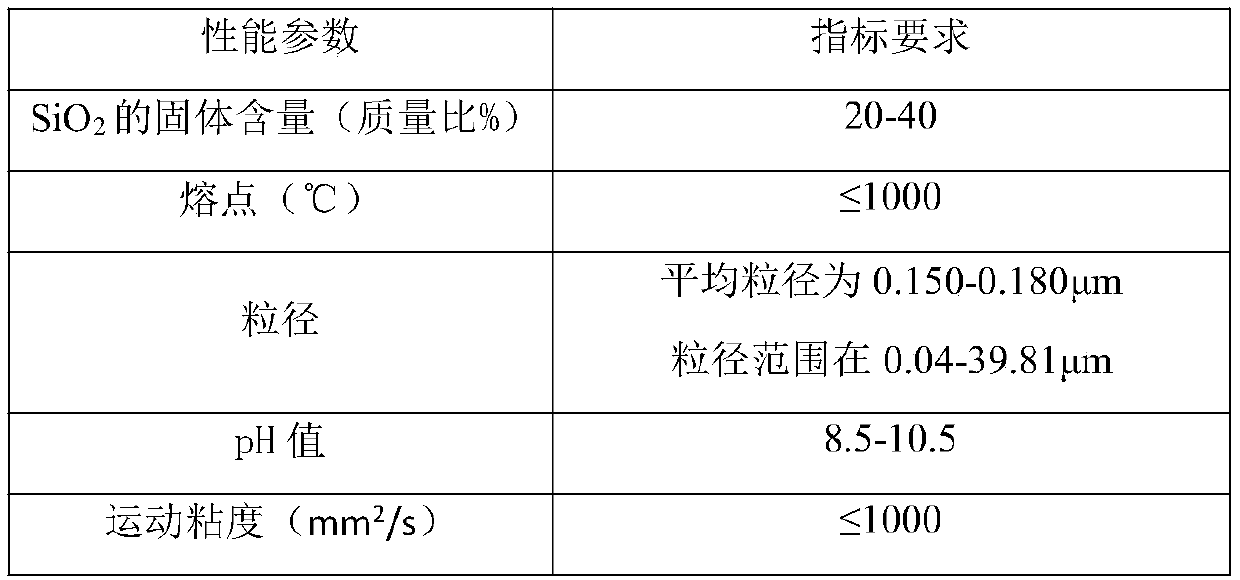

[0036] In the selected nano-scale silica sol, SiO 2 The content is 20wt.%~40wt.%, to ensure that after the silica sol is heated and the water evaporates, the colloidal particles form a porous substance and firmly adhere to the surface of the object, forming a silicon-oxygen bond between the particles, which is a good adhesive The melting point is lower than 1000°C, and it has low-temperature self-sintering characteristics; the pH value is adjusted with s...

Embodiment 2

[0051] The preparation method of embodiment 2 inorganic-inorganic composite slurry

[0052] (1) Nano-scale silica sol (Whilt Technology Co., Ltd. silica sol HS-830) is used as the matrix material, in which SiO 2 The content is 30wt.%, pH value is 9.5, weighs 4kg.

[0053] (2) Get 0.026kg of hydroxyethyl cellulose, make it into 10wt.% aqueous solution, add in the silica sol of step (1) together with 0.054kg of silane coupling agent A172, and mix well;

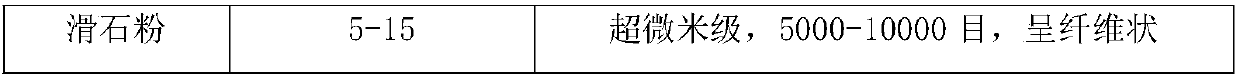

[0054] (3) get 3.6kg particle size and be 3000 purpose alumina powder, 1.7kg particle size be 3000 purpose silica powder and 0.6kg particle size be 10000 purpose fibrous talcum powder, be mixed with filler, add step (2) after mixing uniformly Add the dispersed phase additive to the silica sol, and stir while adding to ensure that the filler is evenly mixed in the silica sol to obtain an inorganic-inorganic composite slurry.

Embodiment 3

[0055] Embodiment 3 The use method of inorganic-inorganic composite slurry

[0056] (1) Use equipment

[0057] The pressure grouting equipment can be used, and the current paint spraying equipment can be borrowed. The specific grouting process is shown as follows.

[0058] The paint spraying operation equipment is putter2000L purchased from Wuxi Putian Special Spraying Equipment Co., Ltd., pressure: 0.1-0.5MPa; flow rate: 20-200 liters / h; storage tank volume: 1-10 liters.

[0059] The nozzle is an L-shaped round pipe with an outer diameter of 7-8mm and an inner diameter of 6-7mm. The nozzle mouth is processed into an oval shape with a short diameter of 5-6mm.

[0060] (2) On-site grouting method for coke oven

[0061] ① Select the carbonization chamber where the cavity between the protective plate and the furnace door frame needs to be grouted, and leave the furnace empty after pushing the coke.

[0062] ② Remove the furnace door and hang the insulation cotton on the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com