Environment-friendly architectural interior wall coating and preparation method thereof

It is an architectural and environment-friendly technology, applied in the direction of coating, etc., which can solve the problems of aging discoloration, easy to fall off, difficult to maintain, etc., and achieve the effect of improving film formation, high transparency, and good product dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

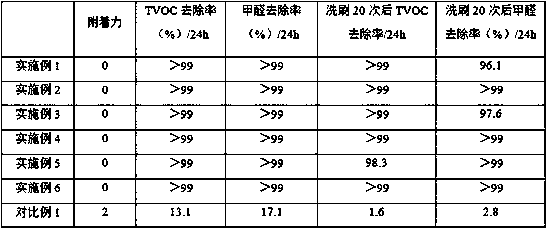

Examples

Embodiment 1

[0031] S1, mix 20 parts of titanium dioxide sol with 15 parts of polyvinyl acetate emulsion, 0.2 parts of dispersant, 10 parts of zinc oxide, and 0.05 parts of coupling agent in 30 parts of water in proportion, and obtain the first mixed dispersion after stirring evenly;

[0032] S2, mix 1 part of defoamer, 0.5 part of leveling agent, 0.01 part of thickener, and 1 part of film-forming aid in 5 parts of water, and stir to obtain the second mixed dispersion;

[0033] S3, slowly mixing the first mixed dispersion liquid and the second mixed dispersion liquid, and stirring evenly to obtain an environment-friendly architectural interior wall paint.

Embodiment 2

[0035] S1, mix 20 parts of titanium dioxide sol with 20 parts of vinyl acetate-acrylate copolymer emulsion, 0.5 parts of dispersant, 12 parts of zinc oxide, and 0.05 parts of coupling agent in 35 parts of water in proportion, and obtain the first mixed dispersion after stirring evenly;

[0036] S2, mix 1 part of defoamer, 0.5 part of leveling agent, 0.01 part of thickener, and 1 part of film-forming aid in 5 parts of water, and stir to obtain the second mixed dispersion;

[0037] S3, slowly mixing the first mixed dispersion liquid and the second mixed dispersion liquid, and stirring evenly to obtain an environment-friendly architectural interior wall paint.

Embodiment 3

[0039] S1, mix 25 parts of titanium dioxide sol with 20 parts of styrene-acrylate copolymer emulsion, 1 dispersant, 15 parts of zinc oxide, and 0.1 part of coupling agent in 40 parts of water in proportion, and obtain the first mixed dispersion after stirring evenly;

[0040] S2, mix 1 part of defoamer, 0.5 part of leveling agent, 0.01 part of thickener, and 1 part of film-forming aid in 5 parts of water, and stir to obtain the second mixed dispersion;

[0041] S3, slowly mixing the first mixed dispersion liquid and the second mixed dispersion liquid, and stirring evenly to obtain an environment-friendly architectural interior wall paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com