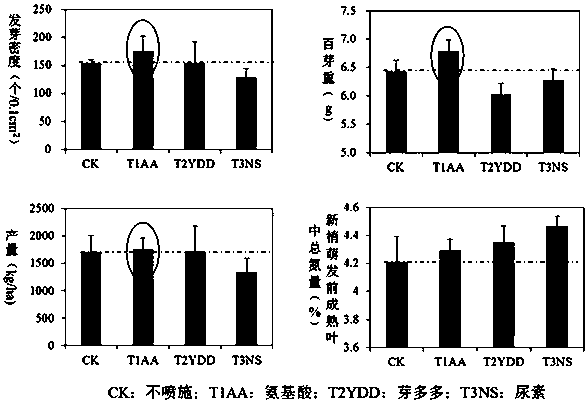

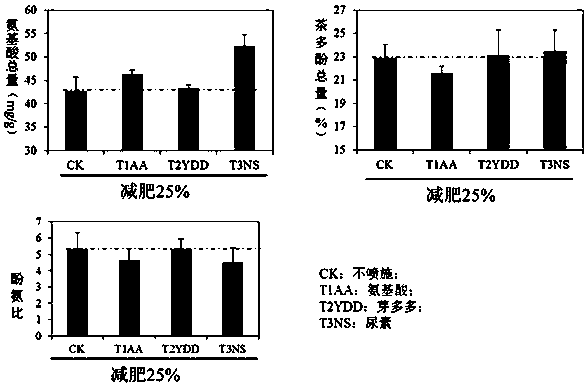

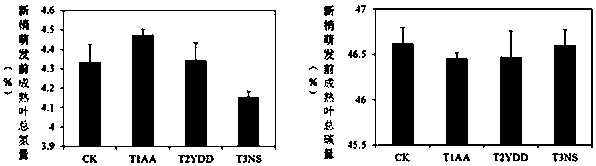

Application method of foliar fertilizer for improving nitrogen storage capacity of tea trees

An application method and foliar fertilizer technology, applied in the direction of fertilization method, nitrogen fertilizer, application, etc., can solve the problems of agricultural non-point source pollution, excessive fertilization, ecological environment, etc., to improve storage nitrogen, reduce application amount, ensure quality and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of the foliage fertilizer that improves tea tree storage nitrogen, specifically comprises the following steps:

[0045] S1. Dissolution of protein: mix dry spirulina powder with water at a mass ratio of 1:50 for rehydration, heat to 50°C, stir at 500r / min, add 0.2wt% sodium carbonate to adjust the pH to 9, colloid Grinding for fine grinding, the temperature is 50°C, 300kg / cm 2 Homogenization for 2 minutes;

[0046] S2. Impurity removal: After the homogeneous solution obtained in step S1 was precipitated for 3 hours, it was centrifuged at 3000r / min to remove solid impurities;

[0047] S3. Precipitate protein: add 1mol / L HCl solution to the liquid in step S2, adjust the pH to about 4.5, produce a large amount of protein precipitation, filter, and collect the solid;

[0048]S4. Redissolving: the solid obtained in step S3 is added to a NaOH solution with a pH of 9, and the protein is redissolved;

[0049] S5. Enzymolysis: Add alkaline proteas...

Embodiment 2

[0051] A kind of preparation method of the foliage fertilizer that improves tea tree storage nitrogen, specifically comprises the following steps:

[0052] S1. Wall breaking and dissolving of protein: mix dry spirulina powder and water at a mass ratio of 1:100 for rehydration, heat to 70°C, stir at 700r / min, add 0.5wt% sodium carbonate to adjust the pH to 10, colloid Grinding for fine grinding, the temperature is 70°C, 300kg / cm 2 Homogenizing for 5 minutes;

[0053] S2. Impurity removal: After the homogeneous solution obtained in step S1 is precipitated for 3-5h, centrifuged at 3000-5000r / min to remove solid impurities;

[0054] S3. Precipitate protein: add 2mol / L HCl solution to the liquid in step S2, adjust the pH to about 4.5, produce a large amount of protein precipitation, filter, and collect the solid;

[0055] S4. Redissolving: the solid obtained in step S3 is added to a NaOH solution with a pH of 10, and the protein is redissolved;

[0056] S5. Enzymolysis: Add alka...

Embodiment 3

[0058] A kind of preparation method of the foliage fertilizer that improves tea tree storage nitrogen, specifically comprises the following steps:

[0059] S1. Wall breaking and dissolving of protein: Mix spirulina dry powder and water at a mass ratio of 1:75 for rehydration, heat to 60°C, stir at 600r / min, add 0.35wt% sodium carbonate to adjust the pH to 9.5, colloid Grinding for fine grinding, the temperature is 60°C, 300kg / cm 2 Homogenization for 3 minutes;

[0060] S2. Impurity removal: After the homogeneous solution obtained in step S1 is precipitated for 4 hours, it is centrifuged at 4000r / min to remove solid impurities;

[0061] S3. Precipitate protein: add 1.5mol / L HCl solution to the liquid in step S2, adjust the pH to about 4.5, produce a large amount of protein precipitation, filter, and collect the solid;

[0062] S4. Redissolving: the solid obtained in step S3 is added to a NaOH solution with a pH of 9.5, and the protein is redissolved;

[0063] S5. Enzymolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com