Hollow oblique metal microneedle array and manufacturing method thereof based on SU-8 mold

A technology of SU-8 and microneedle arrays, applied in the direction of microneedles, metal material coating technology, needles, etc., can solve the problems that the tip of the microneedle is difficult to achieve and the SU-8 mold is difficult to remove, and achieves easy removal and binding force Strong, adhesion-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

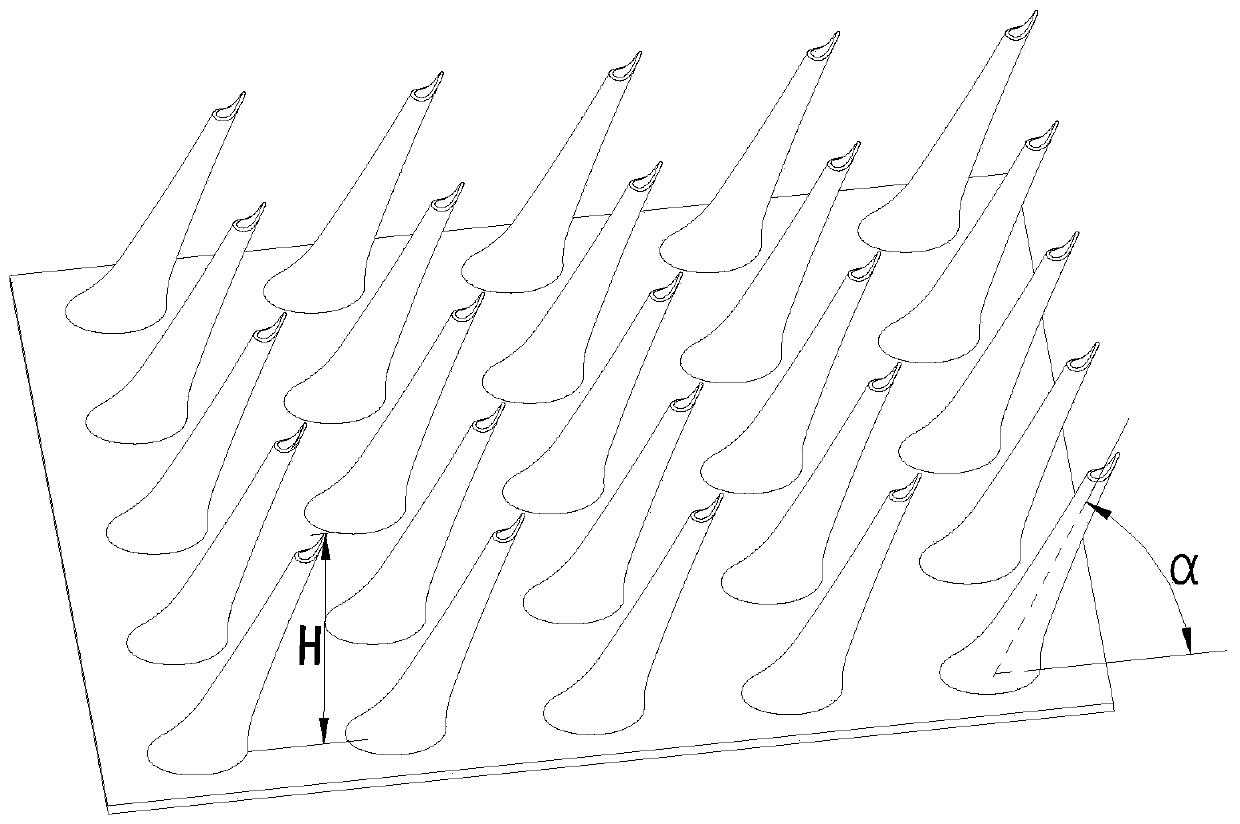

[0052] Referring to Fig. 2, the hollow inclined metal microneedle array aimed at by this embodiment has a microneedle vertical height H of 500 μm; the outer diameter of the bottom of the microneedle is 150 μm; the microneedle inclination angle α is 70°; The wall thickness is 8 μm; the microneedle cone angle is 10°.

[0053] The preparation process of the hollow inclined metal microneedle array of this embodiment is as follows:

[0054] Step 1: Prepare the SU-8 mold on the glass substrate, including the following sub-steps:

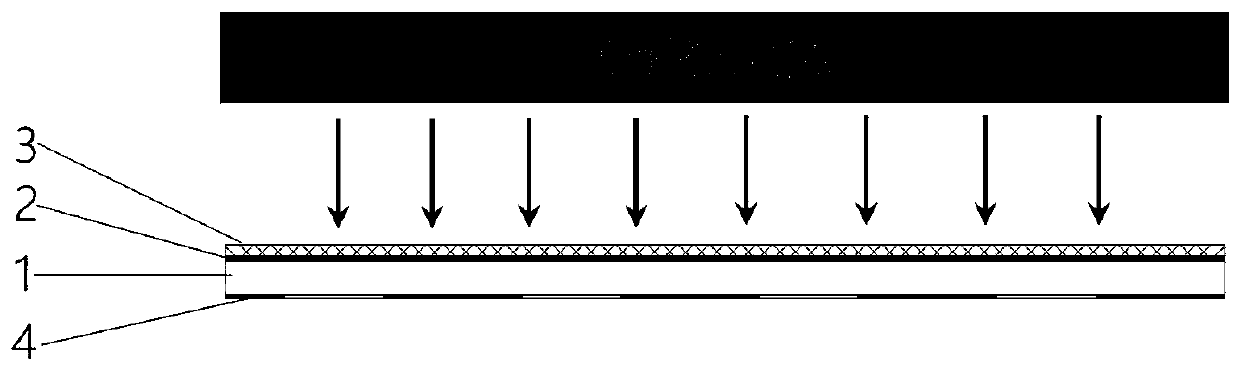

[0055] 1.1 Preparation of SU-8 mold mask pattern on glass substrate

[0056] Clean the quartz glass sheet with a thickness of 500 μm by oxygen plasma; then sputter a layer of 60nm metal chromium on the surface of the quartz glass sheet; spin-coat positive resist on the chromium metal layer, expose the chromium to be corroded after exposure and development, and corrode the metal chromium. After in-liquid etching, the SU-8 mold mask pattern layer 4 is obta...

Embodiment 2

[0077] Referring to Fig. 2, the hollow inclined metal microneedle array aimed at by this embodiment has a microneedle vertical height H of 650 μm; the outer diameter of the bottom of the microneedle is 250 μm; the microneedle inclination angle α is 50°; The wall thickness is 10 μm; the microneedle cone angle is 15°.

[0078] The preparation process of the hollow inclined metal microneedle array of this embodiment is as follows:

[0079] Step 1: Prepare SU-8 mold on glass substrate

[0080] This step includes the following sub-steps:

[0081] 1.1 Preparation of SU-8 mold mask pattern on glass substrate

[0082] Clean the quartz glass sheet with a thickness of 1000 μm by oxygen plasma; then sputter a layer of 60nm metal chromium on the surface of the quartz glass sheet; spin-coat the positive resist on the chromium metal layer, expose the chromium to be corroded after exposure and development, and corrode the metal chromium. After in-liquid etching, the SU-8 mold mask pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com