Polymer plastic for processing plastic pencil holder

A technology of polymer and pencil shaft, which is applied in the direction of pen shaft, non-active pencil, printing, etc., can solve the problems of reducing the aesthetics of plastic pencil curling surface, imperfect appearance of plastic pencil, uneven cells, etc. Improves cleanliness and aesthetics, and facilitates curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

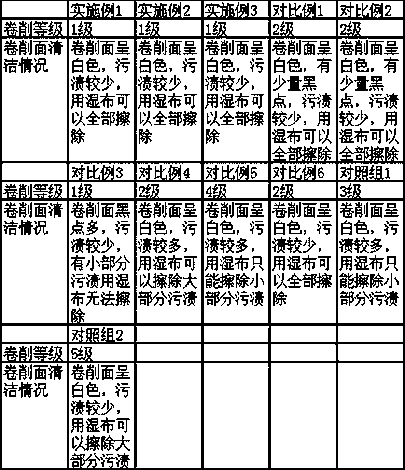

Examples

Embodiment 1

[0021] A polymer plastic used for processing plastic pencil shafts, the specific preparation method is as follows:

[0022] 1) Add chitosan, isopropanol, sodium hydroxide solution and chloroacetic acid into the reactor in sequence, heat up to 50°C, and react for 8 hours. After the reaction is completed, continue to add sodium hydroxide solution and Triethyl-p-nitrobenzyl ammonium chloride, heat up to 65°C, continue to react for 6 hours, then wash with ethanol and isopropanol repeatedly for 3 times, and then use hydrochloric acid to adjust the product to be neutral, and the modified chitosan can be obtained ;

[0023] 2) Add polyvinyl alcohol, modified chitosan, glacial acetic acid and glutaraldehyde to the nano-titanium dioxide dispersion in sequence, stir for 40 minutes in a water bath at 50°C, and rotate at a speed of 150r / min. Dry at ℃ for 8 hours to obtain nano-titanium dioxide / modified chitosan composite, take graphene oxide and add it to deionized water, mix and stir to...

Embodiment 2

[0033] A polymer plastic used for processing plastic pencil shafts, the specific preparation method is as follows:

[0034] 1) Add chitosan, isopropanol, sodium hydroxide solution and chloroacetic acid into the reactor in sequence, heat up to 55°C, react for 7 hours, and continue to add sodium hydroxide solution and Triethyl-p-nitrobenzyl ammonium chloride, heat up to 70°C, continue to react for 5 hours, then wash repeatedly with ethanol and isopropanol for 4 times, and then use hydrochloric acid to adjust the product to be neutral to obtain modified chitosan ;

[0035] 2) Add polyvinyl alcohol, modified chitosan, glacial acetic acid and glutaraldehyde to the nano-titanium dioxide dispersion in turn, stir in a water bath at 55°C for 35min at a speed of 180r / min, and put the product at 65 Dry at ℃ for 7 hours to obtain nano-titanium dioxide / modified chitosan composite, take graphene oxide and add it to deionized water, mix and stir to obtain a graphene oxide dispersion with a ...

Embodiment 3

[0045] A polymer plastic used for processing plastic pencil shafts, the specific preparation method is as follows:

[0046] 1) Add chitosan, isopropanol, sodium hydroxide solution and chloroacetic acid into the reactor in sequence, heat up to 60°C, react for 6 hours, and continue to add sodium hydroxide solution and Triethyl-p-nitrobenzyl ammonium chloride, heat up to 75°C, continue to react for 4 hours, then wash repeatedly with ethanol and isopropanol for 5 times, and then use hydrochloric acid to adjust the product to be neutral to obtain modified chitosan ;

[0047] 2) Add polyvinyl alcohol, modified chitosan, glacial acetic acid and glutaraldehyde to the nano-titanium dioxide dispersion in turn, stir in a water bath at 60°C for 30min at a speed of 200r / min, and put the product at 70 Dry at ℃ for 5 hours to obtain the nano-titanium dioxide / modified chitosan composite, take graphene oxide and add it to deionized water, mix and stir to prepare a graphene oxide dispersion wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com