Biosynthesis method of levodopa

A levodopa and biosynthesis technology, applied in the field of bioengineering, can solve the problems of limited yield and low catalytic efficiency, and achieve the effects of reducing the total cost of production, high yield, and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

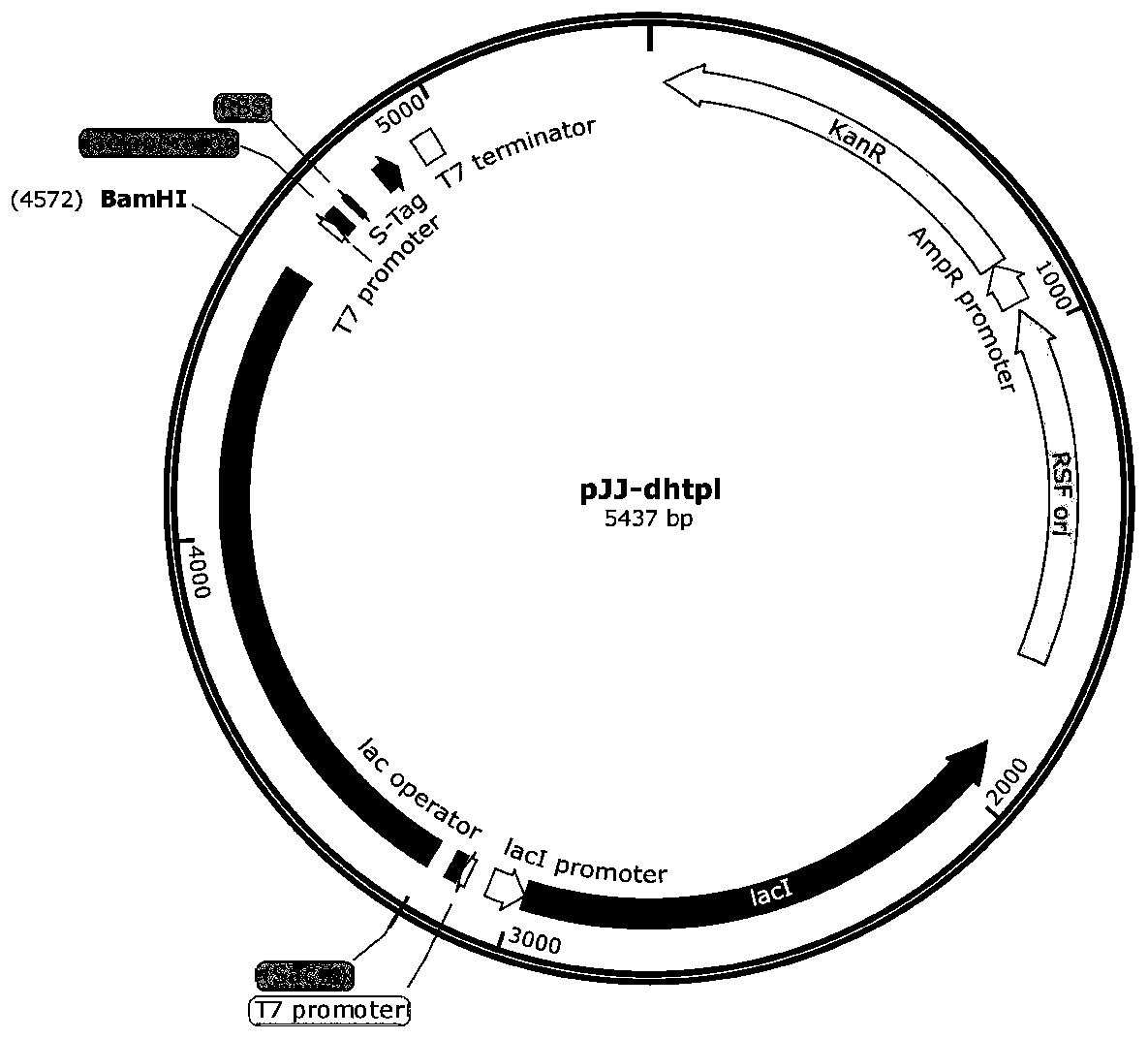

[0048] Escherichia coli Genetic Engineering Bacteria BL21 / pJJ-dhtpl Resting Cells Catalyze the Biosynthesis of Levodopa (without Adding Reactants)

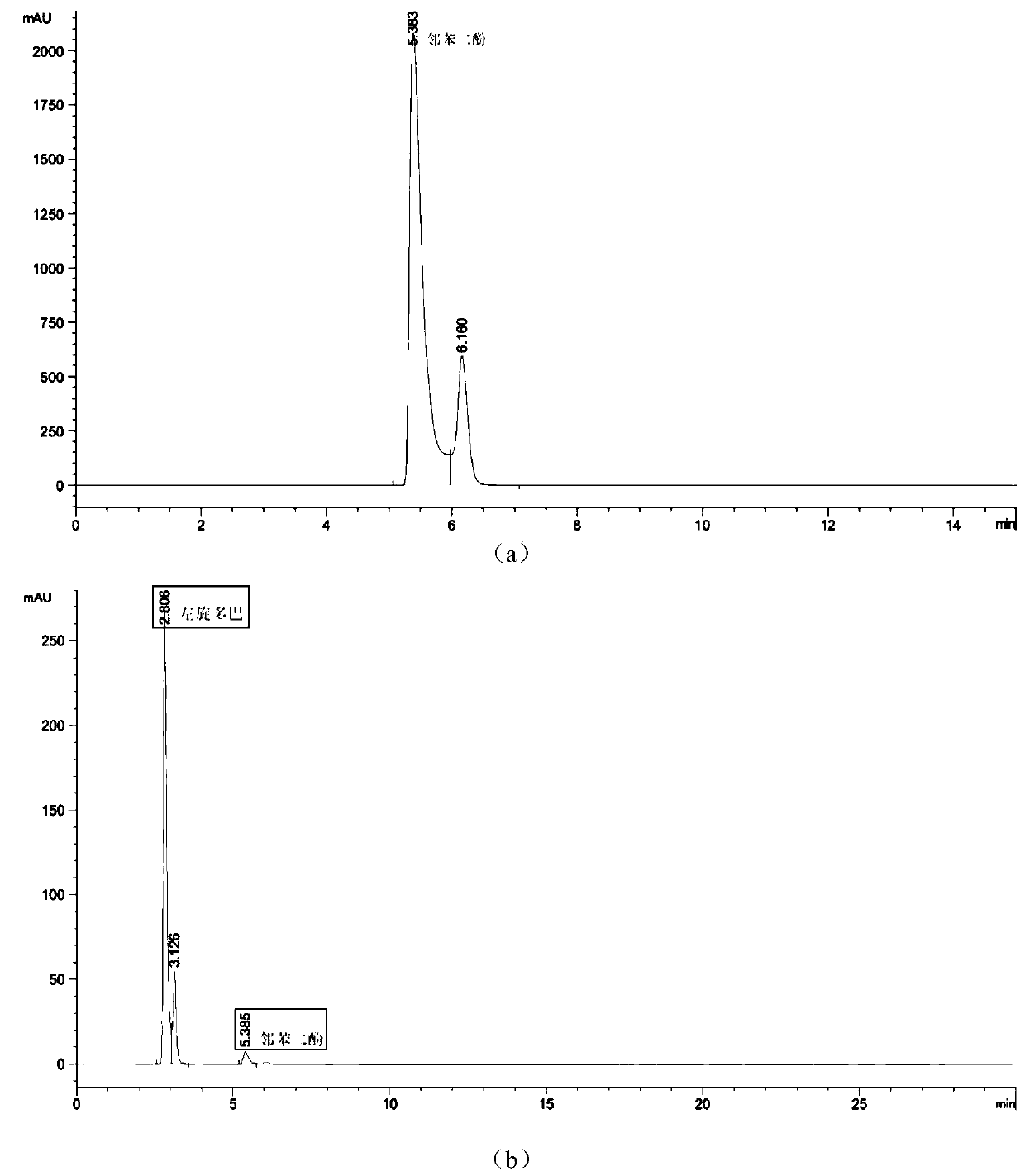

[0049] Adjust the pH with ammonia water to be 1L of sterile water of 8.0 as the reaction solvent, add 5g ammonium pyruvate and 8g catechol, add 12g of E. well mixed. The reaction temperature was 16° C., the stirring speed was 150 r / min, and the reaction was carried out under vacuum for 3 hours. After the reaction, centrifuge (8000r / min, 4°C, 2min), and take the supernatant to measure the content of levodopa. The final molar conversion rate of catechol was 99%, the yield of levodopa was 12.9g / L, and the yield was 91%.

Embodiment 2

[0051] Escherichia coli genetically engineered bacteria BL21 / pJJ-dhtpl resting cells catalyze the biosynthesis of levodopa (reactants added 5 times)

[0052] Adjust the pH with ammonia water to be 1L of sterile water of 8.0 as the reaction solvent, add 5g ammonium pyruvate and 8g catechol, add 12g of E. well mixed. The reaction temperature was 16° C., the stirring speed was 150 r / min, and the reaction was carried out under vacuum for 3 hours. After that, 4 g of ammonium pyruvate and 6.5 g of catechol were added every 3 hours for 3 additional times; and 2 g of ammonium pyruvate and 3.5 g of catechol were added every 3 hours for 2 additional times. After the reaction, centrifuge (8000r / min, 4°C, 2min), and take the supernatant to measure the content of levodopa. The final molar conversion rate of catechol was 96%, the output of levodopa was 55g / L, and the yield was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com