AlGaN/GaN ohmic contact electrode and preparation method and application thereof

A technology of ohmic contact electrodes and electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of increased difficulty in multi-layer metal deposition, reduced yield, unfavorable industrialization, etc., to maintain two-dimensional electron gas concentration, low Effect of electrode surface roughness, low ohmic contact value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

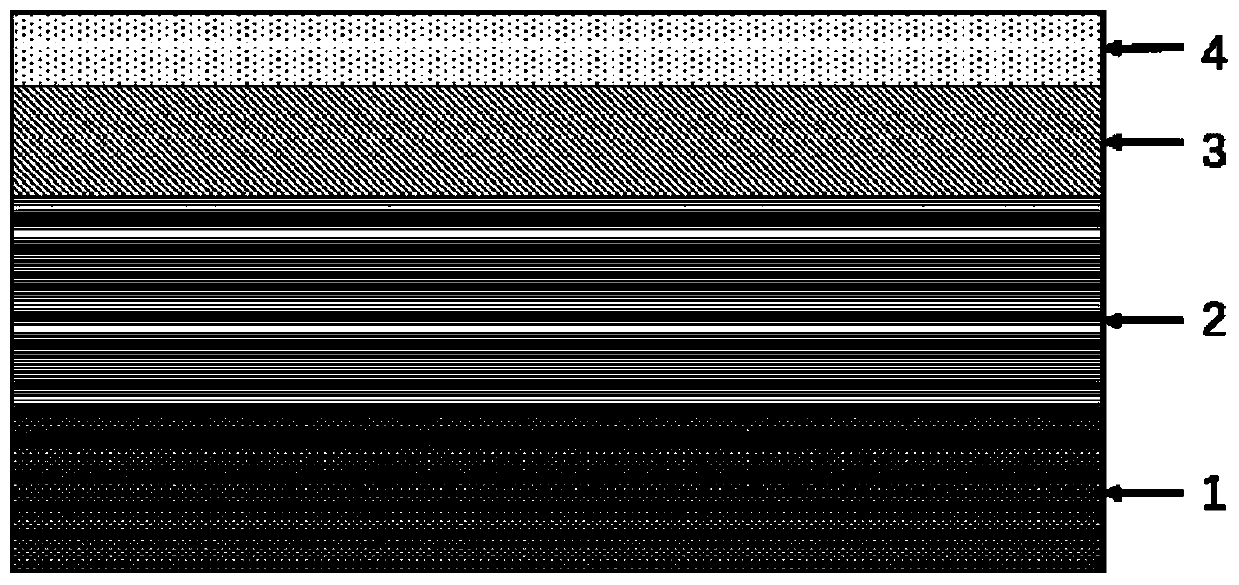

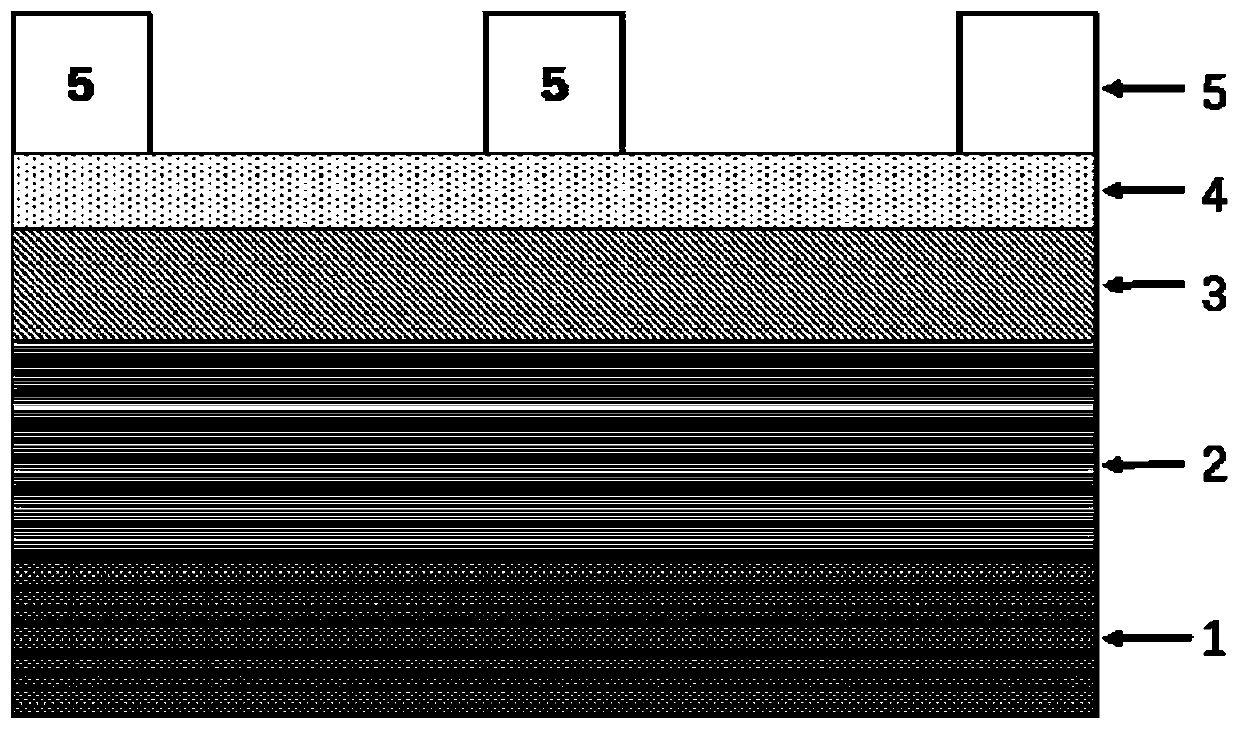

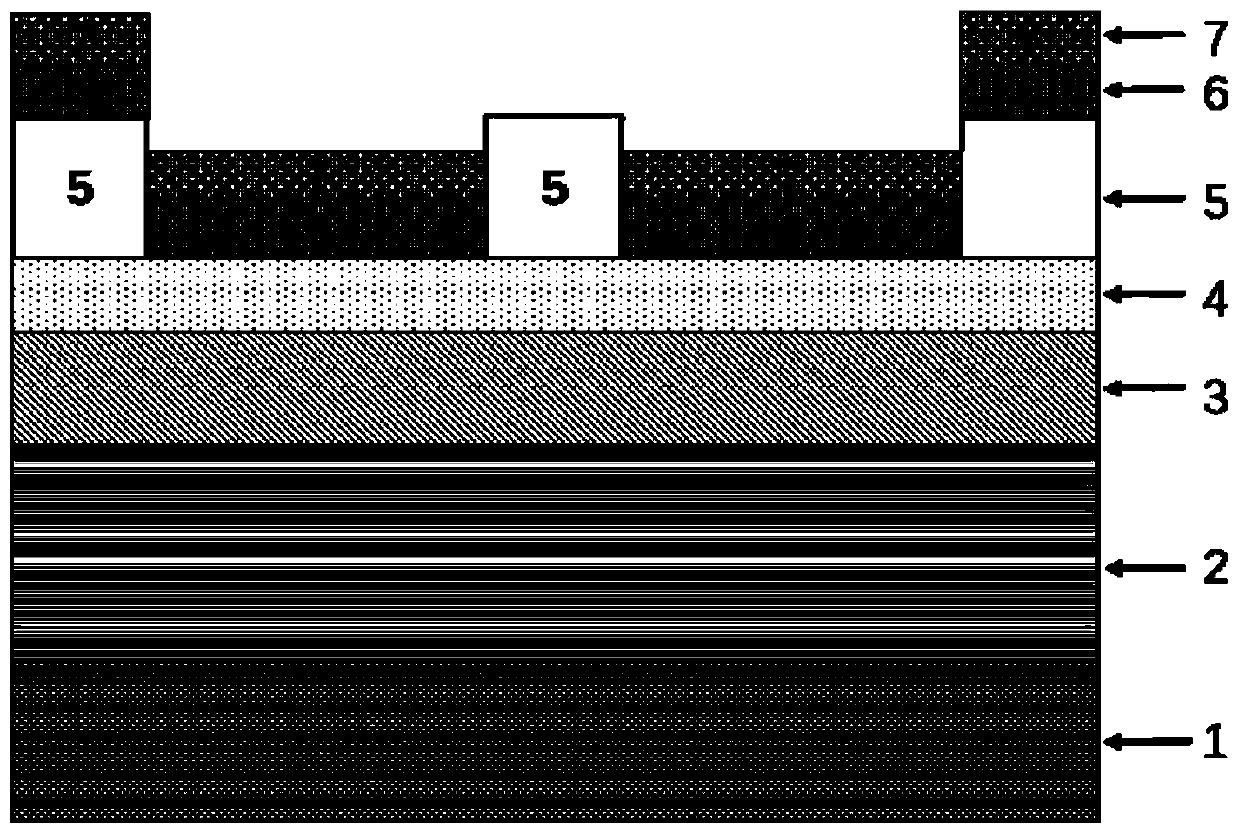

[0060] This embodiment provides a method for preparing an AlGaN / GaN ohmic contact electrode, including the following steps:

[0061] (1) The AlGaN / GaN substrate was ultrasonically cleaned with acetone for 5 minutes, isopropanol for 15 minutes, deionized water for 10 minutes, and dried with nitrogen.

[0062] (2) On the AlGaN layer, perform the process steps of uniform coating, pre-baking, photolithography, development, and post-baking in sequence, define the drain and source patterns, and immerse in HCl:H 2 O=1:4 hydrochloric acid solution for 3 minutes to remove oxides on the surface of the substrate, then rinse with deionized water for 15 minutes, and finally blow dry with nitrogen.

[0063] (3) Immediately put the sample processed in step (2) into the vacuum transfer chamber of the magnetron sputtering equipment to perform the coating process. Ti 10 al 1 The alloy layer is deposited by magnetron sputtering with a thickness of 60nm, and the metal layer of the TiN cap laye...

Embodiment 2

[0066] This embodiment provides a method for preparing an AlGaN / GaN ohmic contact electrode, including the following steps:

[0067] (1) The AlGaN / GaN substrate was ultrasonically cleaned with acetone for 5 minutes, isopropanol for 15 minutes, deionized water for 10 minutes, and dried with nitrogen.

[0068] (2) On the AlGaN layer, perform the process steps of uniform coating, pre-baking, photolithography, development, and post-baking in sequence, define the drain and source patterns, and immerse in HCl:H 2 O=1:4 hydrochloric acid solution for 5 minutes to remove oxides on the surface of the substrate, then rinse with deionized water for 15 minutes, and finally blow dry with nitrogen.

[0069] (3) Immediately put the sample processed in step (2) into the vacuum transfer chamber of the magnetron sputtering equipment to perform the coating process. Ti 5 al 1 The alloy layer is deposited 20nm by magnetron sputtering, and the metal layer of the TiN cap layer is deposited on a T...

Embodiment 3

[0074] This embodiment provides a method for preparing an AlGaN / GaN ohmic contact electrode, including the following steps:

[0075] (1) The AlGaN / GaN substrate was ultrasonically cleaned with acetone for 10 minutes, isopropanol for 5 minutes, deionized water for 15 minutes, and dried with nitrogen.

[0076] (2) On the AlGaN layer, perform the process steps of uniform coating, pre-baking, photolithography, development, and post-baking in sequence, define the drain and source patterns, and immerse in HCl:H 2 O=1:4 hydrochloric acid solution for 2 minutes to remove oxides on the surface of the substrate, then rinse with deionized water for 5 minutes, and finally blow dry with nitrogen.

[0077] (3) Immediately put the sample processed in step (2) into the vacuum transmission chamber of the ion sputtering equipment to perform the coating process. Ti 1 al 1 The alloy layer is deposited by ion sputtering to 40nm, and the metal layer of the TiN cap layer is deposited on a Ti targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com