Method for machining single-tip cone of cathode emitter through laser

A cathode emission and laser processing technology, applied in the field of material processing, can solve problems such as poor environmental protection and low efficiency, and achieve the effects of high-efficiency processing, controllable curvature radius, and pollution-free processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for processing single-tip cones of lanthanum hexaboride cathode emitters by laser, which can prepare single-tip cones of lanthanum hexaboride cathode emitters with a radius of curvature in submicron order, and the radius of curvature can be controlled. Including the following steps:

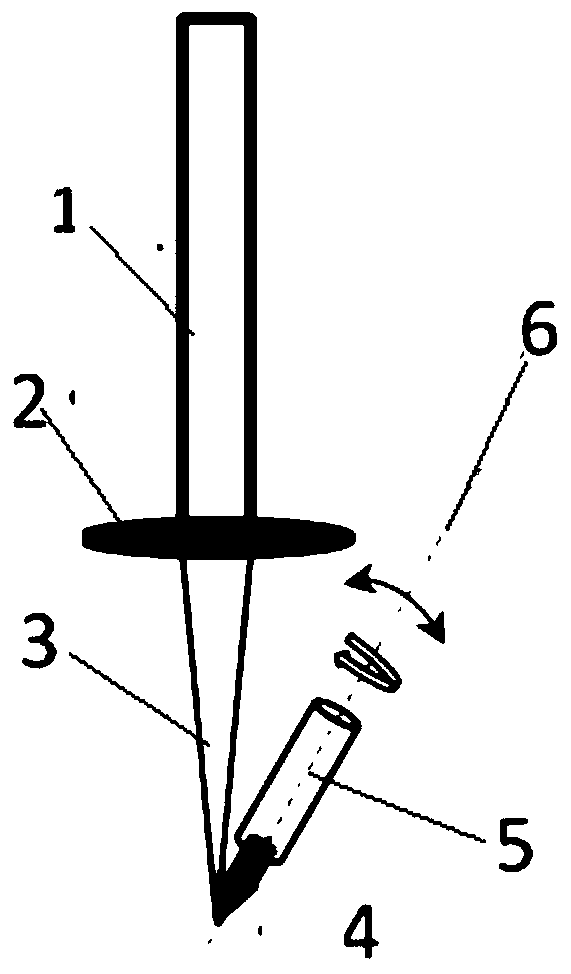

[0025] (1) Femtosecond laser (240fs, 800nm) beam 1 is focused by focusing lens 2 (f=100mm) to form a focused beam 3;

[0026] (2) Install the lanthanum hexaboride cathode emitter 4 (φ10mm×50mm) on the rotatable movement device 5, the rotatable movement device 5 has a two-dimensional rotation mechanism, which can realize the high-speed rotation movement of the lanthanum hexaboride cathode emitter 4 And the angle adjustment between the lanthanum hexaboride cathode emitter 4 and the focused beam 3;

[0027] (3) The rotational speed of the rotatable motion device 5 is set at 100 r / min, and the rotatable motion device 5 is adjusted so that it is 30° to the cen...

Embodiment 2

[0030] This embodiment provides a laser machining method for a tungsten cathode emitter single-tip cone, which can prepare a lanthanum hexaboride cathode emitter single-tip cone with a radius of curvature at the submicron level, and the radius of curvature can be controlled. Including the following steps:

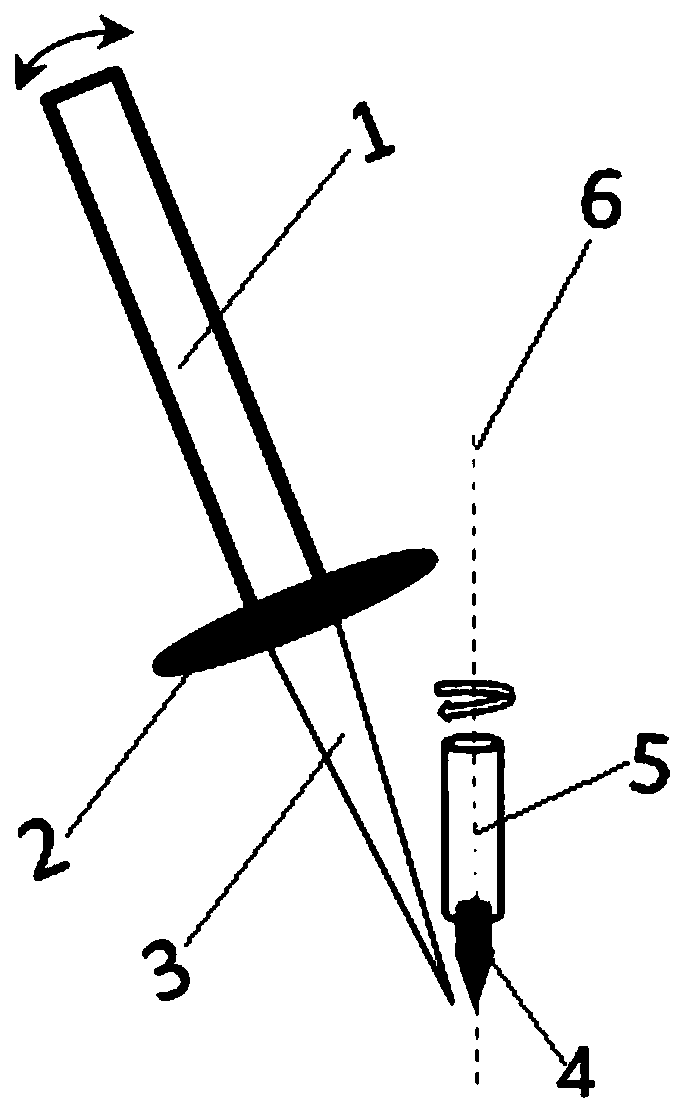

[0031] (1) After the picosecond laser (3fs, 1030nm) beam 1 is focused by the focusing lens 2 (f=150mm), a focused beam 3 is formed;

[0032] (2) Install the tungsten cathode emitter 4 (φ10mm×40mm) on the rotatable motion device 5, the rotatable motion device 5 can realize the high-speed rotary motion of the tungsten cathode emitter 4, and set the rotational speed of the rotatable motion device 5 to 200r / min;

[0033] (3) The focused beam 3 has a tilting and rotating function, and the tilting angle of the focused beam 3 is adjusted so that its central axis and the rotation axis of the tungsten cathode emitter 4 are 45°;

[0034] (4) Using the focused beam 3 to remove materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com