Hazardous waste recovery processing production line

A technology for recycling and processing hazardous wastes, applied in metallurgical wastewater treatment, sludge treatment, water/sludge/sewage treatment, etc. The time required for smelting, the simple structure, and the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

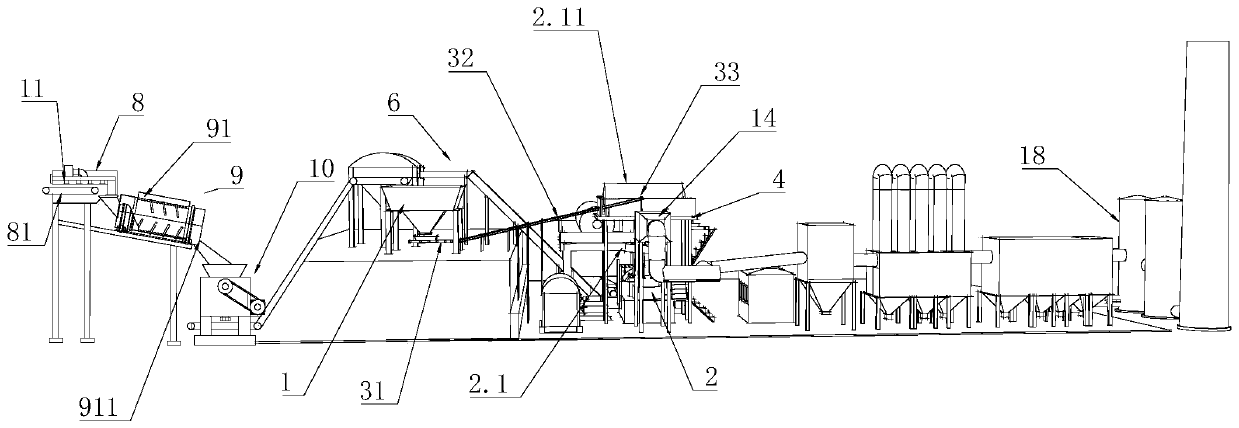

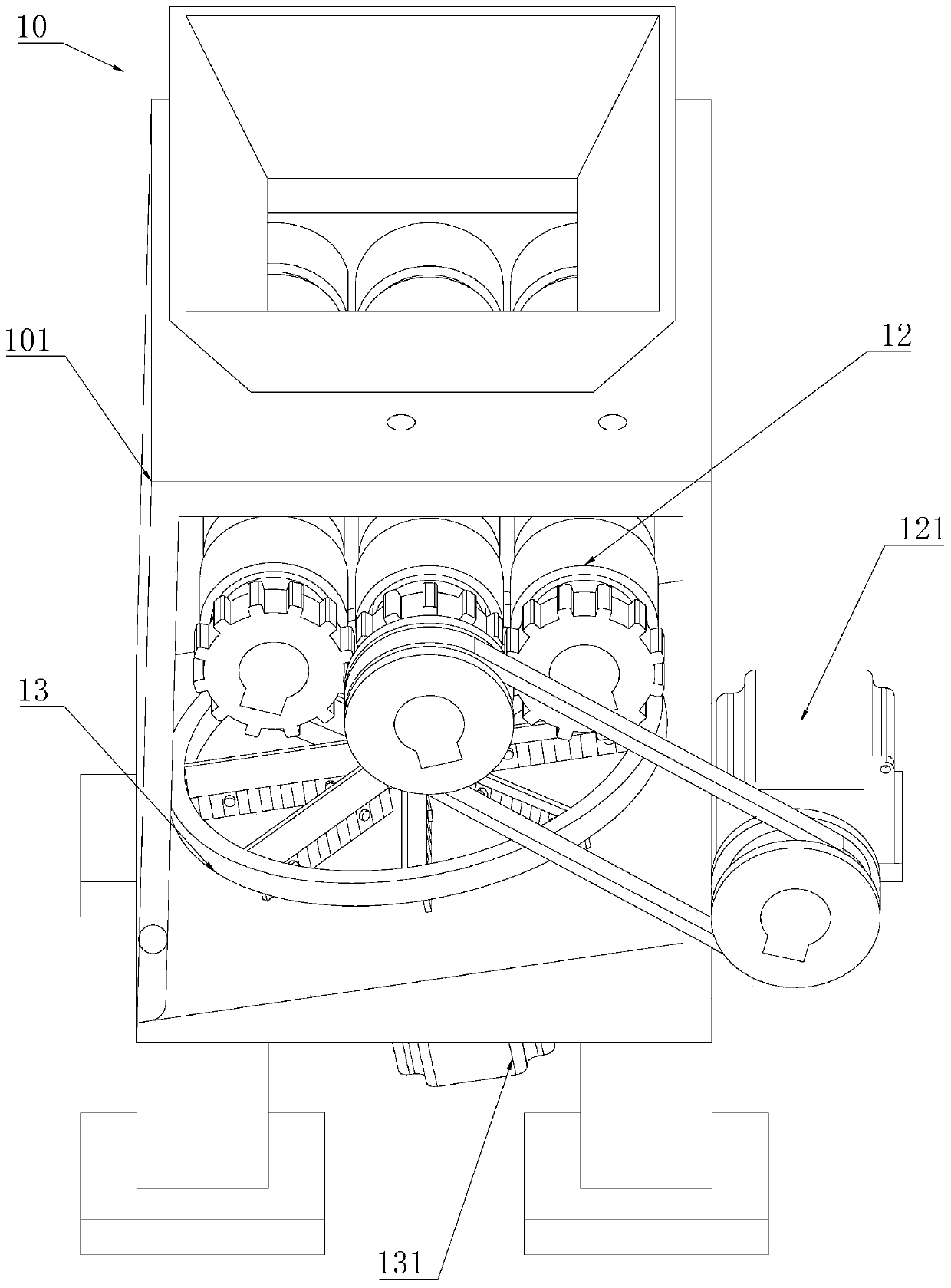

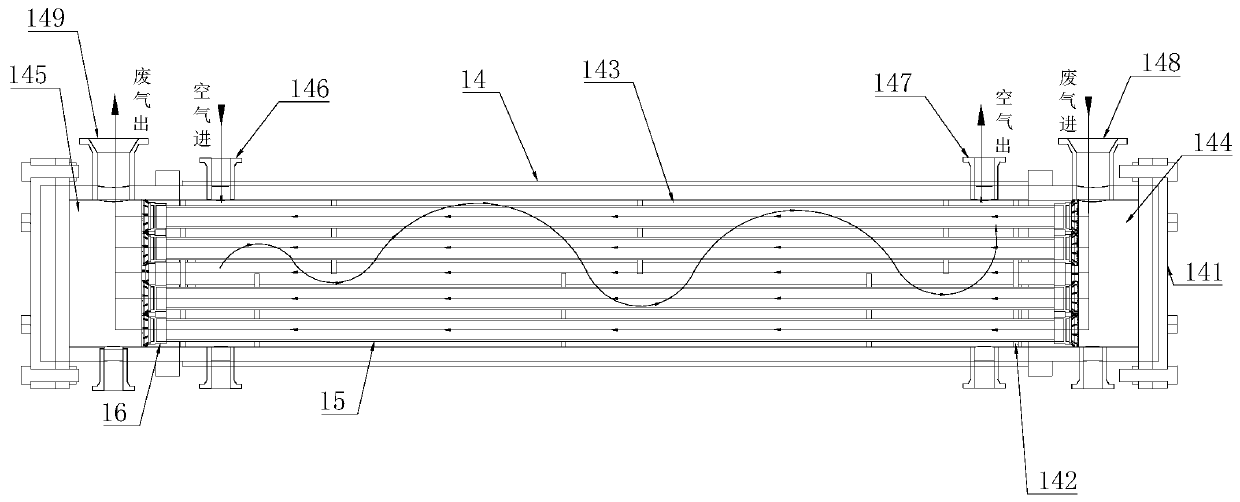

[0042] see Figure 1-13 Shown, a kind of hazardous waste recovery treatment production line of the present invention, this production line comprises:

[0043] A pretreatment device, the pretreatment device is used to sequentially dry and granulate the electroplating sludge, and store the pretreated electroplating sludge in the storage tower 1;

[0044] A smelting device, the smelting device includes a smelting furnace 2 arranged on the right side of the storage tower 1, and the feed port of the smelting furnace 2 receives the electroplating sludge from the storage tower 1 through the transfer belt 3, and the electroplating sludge is deposited by roasting. The sludge is made into a melt, and the outer side of the melting furnace 2 is provided with a water jacket 2.1 for cooling the furnace body, and the water jacket 2.1 is connected to a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com