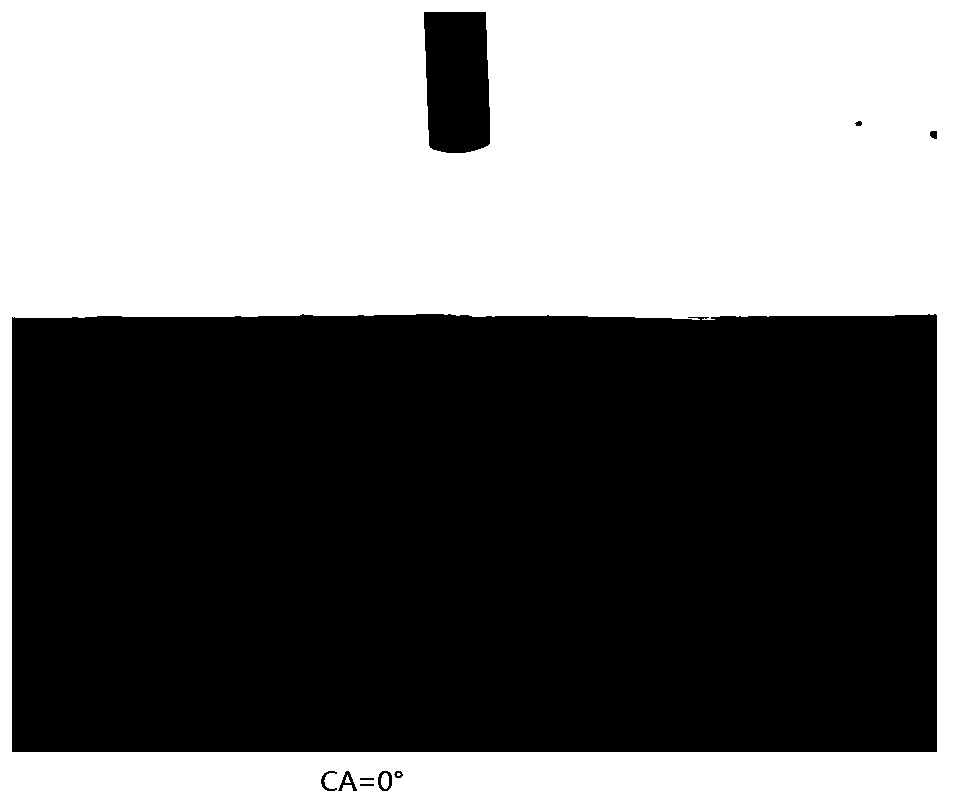

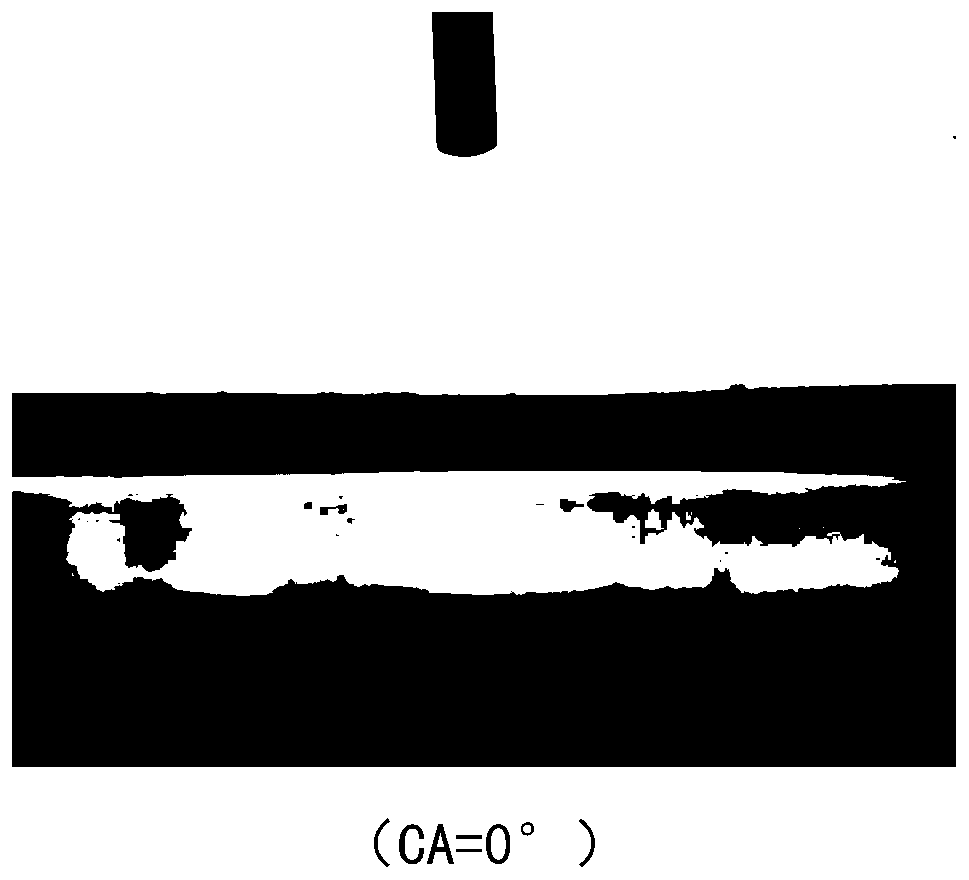

Super-hydrophilic acetylene carbon composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and alkyne carbon, which is applied in the field of membrane separation, can solve the problems of poor hydrophilicity, low flux, and poor pressure tightness of nanofiltration membranes, and achieve simple preparation methods, high-efficiency removal, and low-cost preparation raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

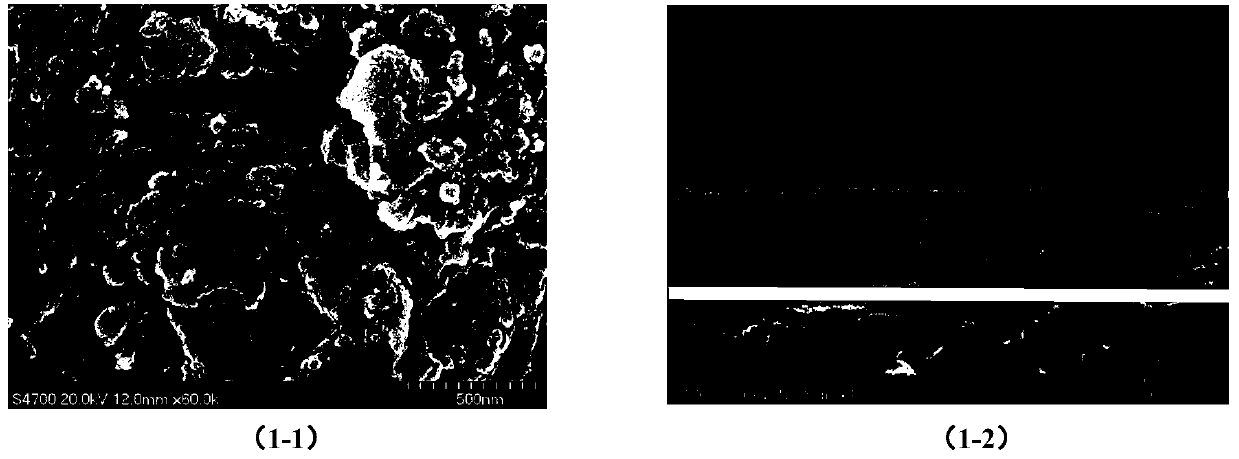

[0033] Examples of the present invention provide the preparation method of the above-mentioned alkyne-carbon composite membrane, comprising:

[0034] Step a, washing the porous substrate with organic and inorganic solvents multiple times to remove surface organic matter and inorganic dust;

[0035] Step b. Accurately weigh a certain amount of alkyne carbon material, disperse it in a buffer solution, and perform ultrasonic treatment for a certain period of time to obtain a uniform alkyne carbon dispersion. Then add organic matter containing dopamine structure into the prepared dispersion liquid, add the prepared polyethyleneimine solution into it after stirring treatment, stir and ultrasonically treat alternately for 4-10 hours.

[0036] Step c, immerse the porous substrate treated in step a in the dispersion liquid obtained in step b for 1-12 hours, transfer it to a crosslinking agent solution after forming a film on the surface of the substrate for crosslinking treatment, and...

Embodiment 1

[0046] Use polyacrylonitrile (PAN) porous base membrane, the average pore size of the base membrane is 0.04um; choose CaC 2 The alkyne carbon material prepared by reacting with hexabromobenzene in a ball mill was used as an additive.

[0047] Step a, wash the PAN40 porous substrate with 30wt% ethanol solution for several times and then immerse it for 4 hours to remove surface organic matter, then rinse it with deionized water several times and then immerse it in deionized water for later use;

[0048] Step b. Accurately weigh 0.2 g of alkyne carbon material, disperse it in 400 ml of Tris-HCl buffer solution with pH=8.5, and use ultrasonic treatment for 2 hours to obtain a uniform alkyne carbon dispersion. Then, 0.8 g of dopamine hydrochloride was added to the prepared dispersion, and after stirring treatment, 4 g of prepared polyethyleneimine was added therein, and stirred and ultrasonically treated alternately for 4 hours.

[0049] Step c, immerse the PAN substrate treated i...

Embodiment 2

[0055] Use polyacrylonitrile (PAN) porous base membrane, the average pore size of the base membrane is 0.04um; choose CaC 2 The alkyne carbon material prepared by reacting with hexabromobenzene in a ball mill was used as an additive.

[0056] Step a, wash the PAN40 porous substrate with 50wt% ethanol solution several times, then immerse it in it for 4 hours to remove surface organic matter, then rinse it with deionized water several times and then immerse it in deionized water for later use;

[0057] Step b. Accurately weigh 0.2 g of the alkyne carbon material, disperse it in 400 ml of Tris-HCl buffer solution with pH=8.5, and use ultrasonic treatment for 3 hours to obtain a uniform alkyne carbon dispersion. Then, 0.8 g of dopamine hydrochloride was added to the prepared dispersion, and after stirring treatment, 4 g of prepared polyethyleneimine was added therein, and stirred and ultrasonically treated alternately for 4 hours.

[0058] Step c, immerse the PAN substrate treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com