Carbon-doped mesoporous graphitized carbon nitride nanospheres and its preparation method and application

A carbon nitride and graphitization technology, applied in the field of doping modification of semiconductor materials, can solve the problems of high cost, poor dispersion, poor conductivity, etc., and achieve excellent electrocatalytic hydrogen evolution activity, high conductivity and dispersibility, The effect of good dispersibility and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a carbon-doped mesoporous graphitized carbon nitride nanosphere, the preparation method of the carbon-doped mesoporous graphitized carbon nitride nanosphere comprises:

[0070] Pre-oxidize the wet wipes with dilute nitric acid with a concentration of 2M at 60°C for 1 hour to obtain pre-oxidized biomass fibers;

[0071] Weigh 0.2g pre-oxidized biomass fiber and 1.5g thiourea, and disperse in 20mL H 2 O, then hydrothermally treated at 100°C for 24h, and finally dried at 80°C for 5h to obtain a white solid, that is, a wet tissue fiber loaded with thiourea.

[0072] The white solid was placed in an air atmosphere, heated to 550°C at a rate of 5°C / min, and then kept at 550°C for 2h to obtain carbon-doped graphitized carbon nitride nanospheres.

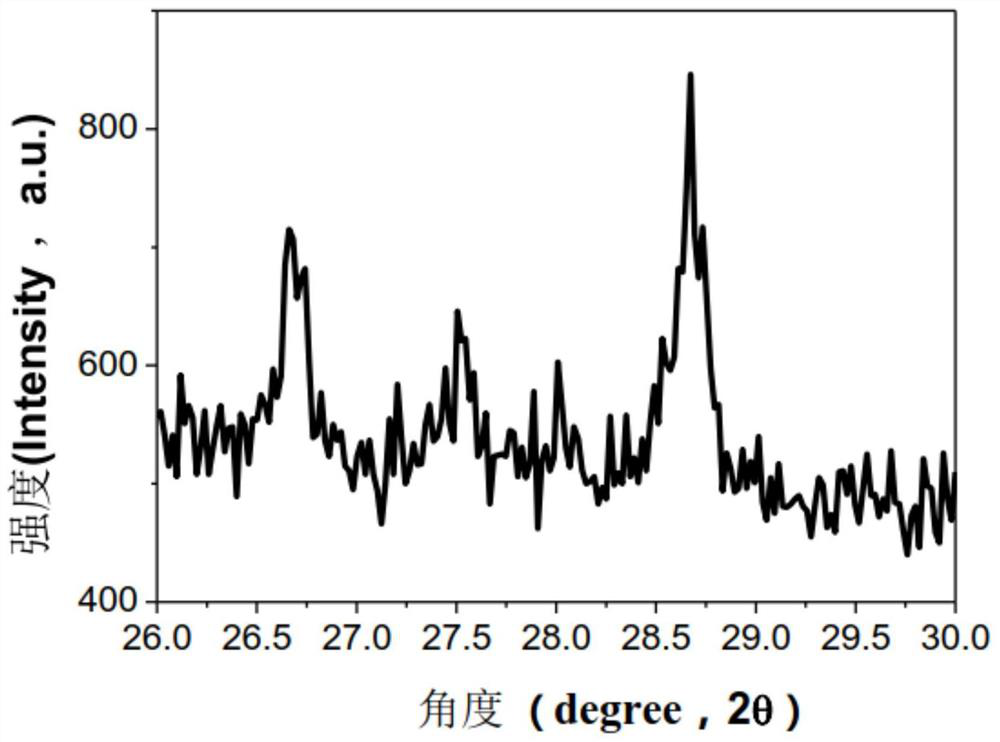

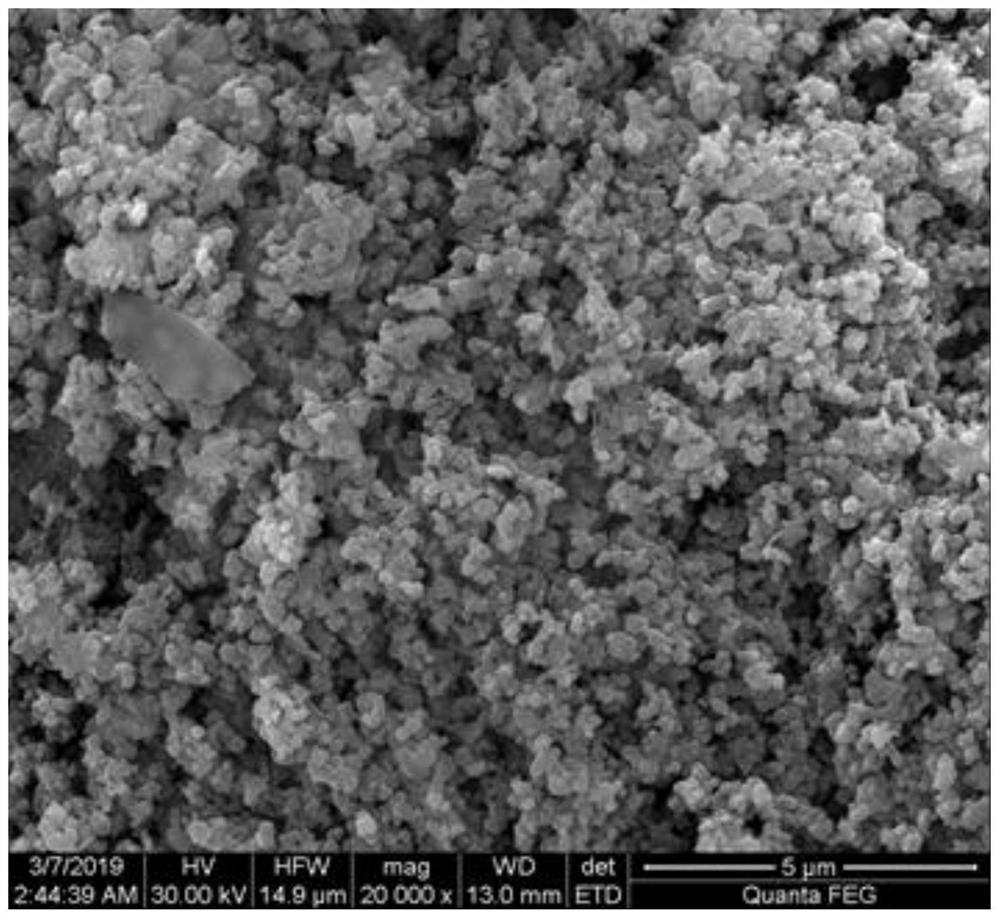

[0073] The XRD spectrum of the carbon-doped graphitized carbon nitride nanospheres provided by the present embodiment is as follows: Figure 1A , Figure 1B As shown, the SEM pattern is as Figure 2A , Fig...

Embodiment 2

[0078] This embodiment provides a carbon-doped mesoporous graphitized carbon nitride nanosphere, the preparation method of the carbon-doped mesoporous graphitized carbon nitride nanosphere comprises:

[0079] Pre-oxidize the paper towels with dilute nitric acid with a concentration of 2M at 60°C for 1 hour to obtain pre-oxidized biomass fibers;

[0080] Weigh 0.2g pre-oxidized biomass fiber, 1.5g thiourea and 1.5g dicyandiamide, and disperse in 16mL H 2 O and 4 mL of ethanol, then hydrothermally treated at 100 °C for 2 days, and finally vacuum-dried at 80 °C for 5 h to obtain a white solid that is a wet tissue fiber loaded with thiourea and dicyandiamide.

[0081] The white solid was placed in an air atmosphere, heated to 500°C at a rate of 2°C / min, and then kept at 500°C for 4h to obtain carbon-doped graphitized carbon nitride nanospheres.

Embodiment 3

[0083] This embodiment provides a carbon-doped mesoporous graphitized carbon nitride nanosphere, the preparation method of the carbon-doped mesoporous graphitized carbon nitride nanosphere comprises:

[0084] Pre-oxidize the carbon cloth with dilute nitric acid with a concentration of 2M at 60°C for 1 hour to obtain pre-oxidized biomass fibers;

[0085] Weigh 0.2g preoxidized biomass fiber, 1.5g thiourea and 1.5g dicyandiamide, and disperse in 10mL H 2 O and 10 mL of ethanol, then hydrothermally treated at 100 °C for 2 days, and finally vacuum-dried at 80 °C for 5 h to obtain a white solid that is a wet tissue fiber loaded with thiourea and dicyandiamide.

[0086] The white solid was placed in an air atmosphere, heated up to 600°C at a rate of 15°C / min, and then kept at 600°C for 2h to obtain carbon-doped graphitized carbon nitride nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com