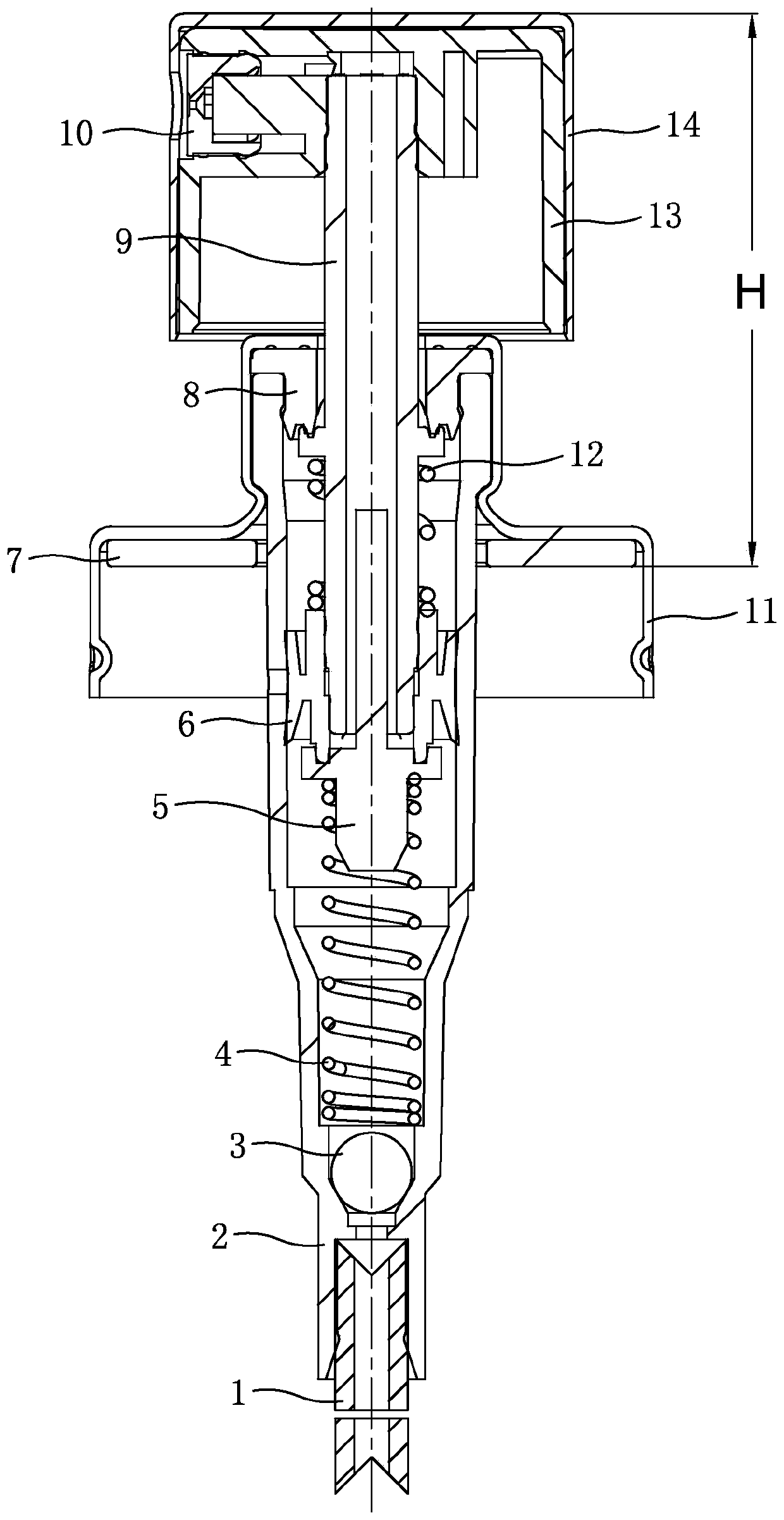

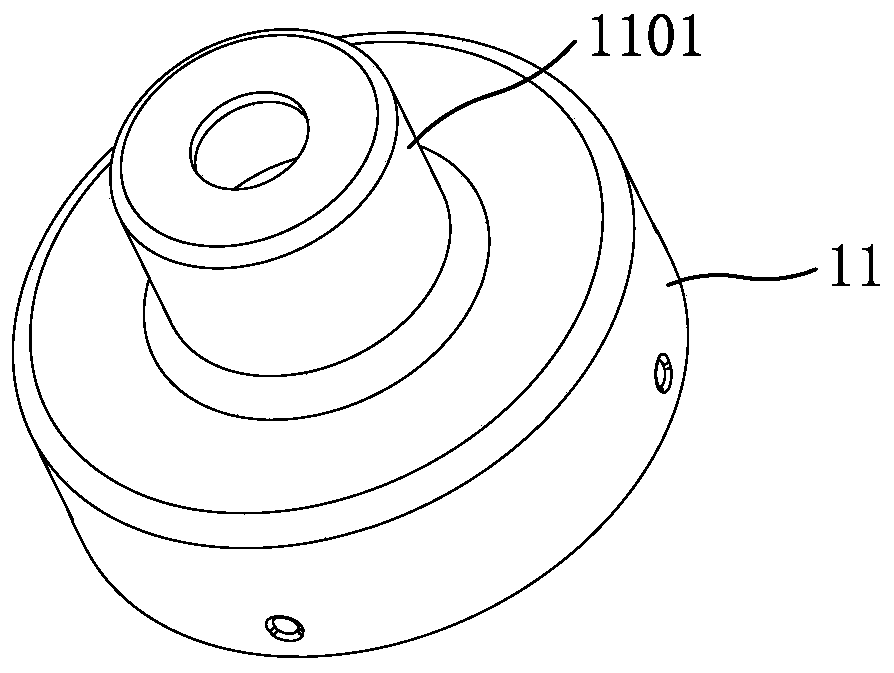

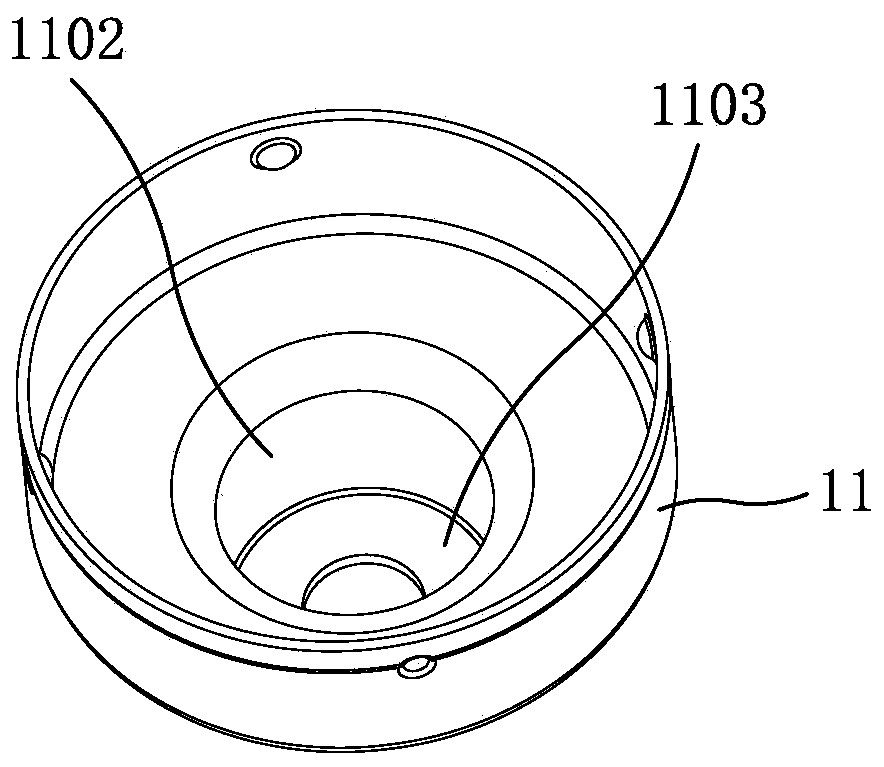

Environment-friendly high-rigidity pressing type atomizer and manufacturing method thereof

A high-rigidity, press-type technology, applied in the direction of injection devices, single handheld devices, etc., can solve the problems of poor structural design of alumina bayonet and inner plug, poor environmental protection and high rigidity, etc., to achieve a feasible preparation method, Good sealing performance and increased discharge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mass parts of antibacterial PE masterbatch are: 50 parts of polyvinyl chloride, 6 parts of calcium zinc heat stabilizer, 20 parts of filler, 20 parts of chlorinated polyethylene, 1 part of lubricant, 1 part of antioxidant phosphite, polyethylene 1 part of wax, 20 parts of environment-friendly plasticizer, 15 parts of antibacterial agent, antibacterial agent is zeolite type nano-silver ion antibacterial agent, and filler is calcium carbonate. The above mass parts of polyvinyl chloride and chlorinated polyethylene are added to a high-speed mixer for high-speed mixing at a speed of 300 / min. After mixing for 5 minutes, the mixing temperature is 60 ° C. While stirring at a high speed, add Plasticizer: After the plasticizer is fully absorbed by polyvinyl chloride and chlorinated polyethylene, cool to room temperature, and then add calcium zinc heat stabilizer, filler, lubricant, polyethylene wax, and antibacterial agent in sequence according to certain parts by mass. Then m...

Embodiment 2

[0027] The mass parts of antibacterial PE masterbatch are: 65 parts of polyvinyl chloride, 8 parts of calcium zinc heat stabilizer, 25 parts of filler, 25 parts of chlorinated polyethylene, 2 parts of lubricant, 1.5 parts of antioxidant phosphite, polyethylene 1.5 parts of wax, 25 parts of environment-friendly plasticizer, 17.5 parts of antibacterial agent, antibacterial agent is zeolite type nano-silver ion antibacterial agent, and filler is calcium carbonate. The above mass parts of polyvinyl chloride and chlorinated polyethylene are added to a high-speed mixer for high-speed mixing at a speed of 400 / min. After mixing for 7 minutes, the mixing temperature is 65°C. While stirring at a high speed, add Plasticizer: After the plasticizer is fully absorbed by polyvinyl chloride and chlorinated polyethylene, cool to room temperature, and then add calcium zinc heat stabilizer, filler, lubricant, polyethylene wax, and antibacterial agent in sequence according to certain parts by mass...

Embodiment 3

[0029] The mass parts of antibacterial PE masterbatch are: 80 parts of polyvinyl chloride, 10 parts of calcium zinc heat stabilizer, 30 parts of filler, 30 parts of chlorinated polyethylene, 3 parts of lubricant, 2 parts of antioxidant phosphite, polyethylene 2 parts of wax, 30 parts of environment-friendly plasticizer, 20 parts of antibacterial agent, antibacterial agent is zeolite type nano-silver ion antibacterial agent, and filler is talcum powder. The above mass parts of polyvinyl chloride and chlorinated polyethylene are added to a high-speed mixer for high-speed mixing at a speed of 500 / min. After mixing for 10 minutes, the mixing temperature is 70°C. While stirring at a high speed, add Plasticizer: After the plasticizer is fully absorbed by polyvinyl chloride and chlorinated polyethylene, cool to room temperature, and then add calcium zinc heat stabilizer, filler, lubricant, polyethylene wax, and antibacterial agent in sequence according to certain parts by mass. Then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com