A preparation method of investment casting nodular cast iron qt450-10l

A technology of investment precision casting and nodular cast iron, which is applied to casting molding equipment, casting molds, and casting mold components, can solve the problems of slow cooling speed, poor quality of investment casting graphite spheroidization, and unstable matrix structure, etc., to achieve Effect of improving low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

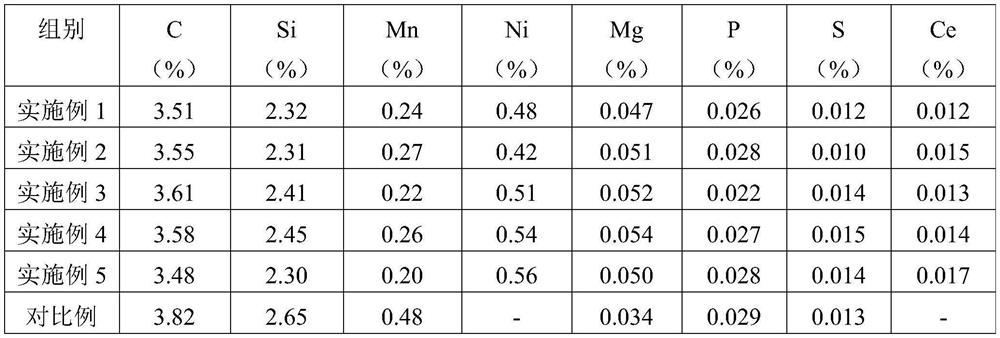

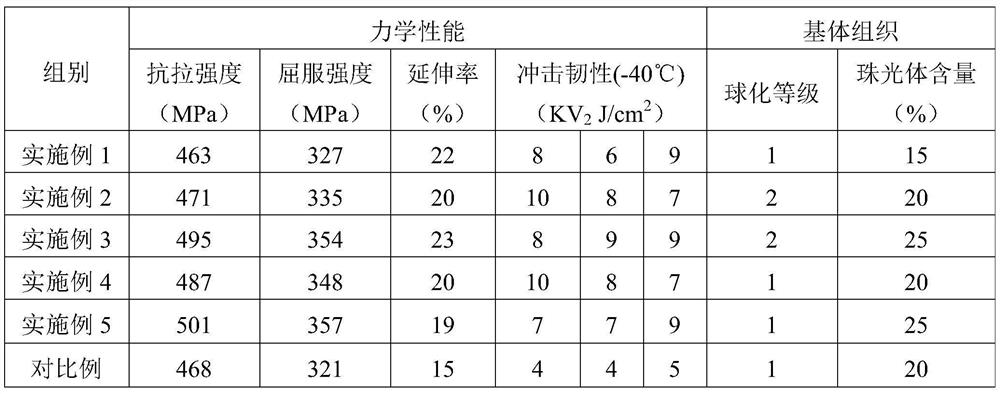

Embodiment 1

[0033] This embodiment discloses a preparation method of investment casting nodular cast iron QT450-10L, which includes the following steps:

[0034] Shell making and firing of investment casting shells: the mixture of silica sol and quartz sand is used as the surface coating of the shell, wherein the mass ratio of silica sol:quartz sand is 1:1.9, and the mixture of silica sol and mullite is used as the coating. The back layer coating of the shell, in which the mass ratio of silica sol: mullite is 1:1.8, the surface layer is sanded with quartz sand, and the back layer is sanded with mullite sand, and the shell is roasted in a through-type natural gas roasting furnace , The firing temperature is controlled at 900-950°C, and the firing time is 2.5h.

[0035] Melting of molten iron: The molten iron is smelted by an intermediate frequency induction circuit, and the furnace materials are 200kg of Q10 pig iron, 200kg of recycled materials, 100kg of scrap steel and 3.5kg of low-sulfu...

Embodiment 2

[0041] This embodiment discloses a preparation method of investment casting nodular cast iron QT450-10L, which includes the following steps:

[0042] Shell making and firing of investment casting shells: a mixture of silica sol and quartz sand is used as the surface coating of the shell, wherein the mass ratio of silica sol:quartz sand is 1:2.1, and a mixture of silica sol and mullite is used as the coating. The back layer coating of the shell, in which the mass ratio of silica sol: mullite is 1:2.3, the surface layer is sanded with quartz sand, and the back layer is sanded with mullite sand, and the shell is roasted in a through-type natural gas roasting furnace , The firing temperature is controlled at 900-950°C, and the firing time is 3.5h.

[0043] Molten iron smelting: use medium frequency induction circuit to smelt molten iron, and select 300kg Q10 pig iron, 100kg recycled material, 100kg scrap steel and 4.5kg low-sulfur graphite recarburizer as the charge.

[0044] Sph...

Embodiment 3

[0049] This embodiment discloses a preparation method of investment casting nodular cast iron QT450-10L, which includes the following steps:

[0050] Shell making and firing of investment casting shell: the mixture of silica sol and quartz sand is used as the surface coating of the shell, the mass ratio of silica sol:quartz sand is 1:2, and the mixture of silica sol and mullite is used as the coating. The back layer coating of the mold shell, in which the mass ratio of silica sol: mullite is 1:2, the surface layer is sanded with quartz sand, and the back layer is sanded with mullite sand, and the mold shell is roasted in a through-type natural gas roasting furnace , The firing temperature is controlled at 900-950°C, and the firing time is 3h.

[0051] Melting of molten iron: use medium frequency induction circuit to smelt molten iron, and select 250kg of Q10 pig iron, 200kg of recycled material, 50kg of scrap steel and 3.8kg of low-sulfur graphite recarburizer as the charge. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com