Waterproof anti-cracking fully-recycled aggregate foamed block based on macro-micro double-pore structure and preparation method thereof

A recycled aggregate and dual-porosity technology, which is applied in the manufacture of tools, ceramic products, and other household appliances, etc., to achieve the effects of light material, improved city appearance, and good shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

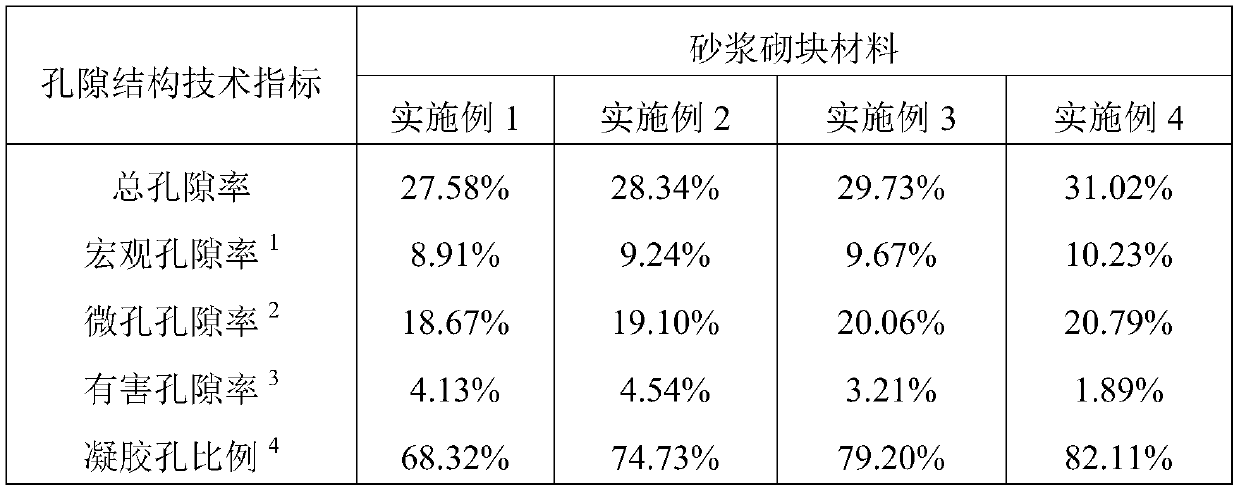

Examples

Embodiment 1

[0038] 1) Take the components according to the mass fraction ratio: polyvinyl alcohol fiber 0%; fully recycled aggregate 50%; polycarboxylate superplasticizer 0%; Portland cement 15%; fly ash 0%; foam 0% agent; 0% air-entraining agent; the rest is water, and the sum of the above components is 100%.

[0039] 2) Mix water, water reducing agent and portland cement evenly and place in a mixer for slow stirring for 1-2 minutes, the speed of the mixer is 140±5r / min, and fully foam for 2-3 minutes; then fully regenerated bone Add the material into the mixer, stir at a slow speed for 2-3 minutes until the mixture is uniform, and obtain the material for the recycled aggregate foam block; finally, add the material for the fully recycled aggregate foam block into the mold of the mortar test piece at one time, and cast it into shape , Prepared into a 40mm*40mm*160mm test piece.

[0040] The fully recycled aggregate foam concrete specimen obtained by the above method shall be placed in a ...

Embodiment 2

[0042] 1) Take the components according to the mass fraction ratio: polyvinyl alcohol fiber 0%; fully recycled aggregate 55%; polycarboxylate superplasticizer 0.2%; Portland cement 18%; fly ash 2%; foam 0% agent; 0% air-entraining agent; the rest is water, and the sum of the above components is 100%.

[0043] 2) Mix water, water reducing agent, portland cement and fly ash evenly and place in a mixer for slow stirring for 1-2 minutes, the speed of the mixer is 140±5r / min, fully foam for 2-3 minutes; Add the fully recycled aggregate into the mixer, stir at a slow speed for 2-3 minutes until the mixture is uniform, and obtain the material for the fully recycled aggregate foam block; finally, add the fully recycled aggregate foam block material into the mortar test piece at a time In the mould, cast and form, and prepare a 40mm*40mm*160mm test piece.

[0044] The fully recycled aggregate foam concrete specimen obtained by the above method shall be placed in a steam curing room af...

Embodiment 3

[0047] 1) Take the components according to the mass fraction ratio: polyvinyl alcohol fiber 0.02%; fully recycled aggregate 55%; polycarboxylate superplasticizer 0.3%; Portland cement 18%; fly ash 3%; foam 0.2% of air-entraining agent; 0.03% of air-entraining agent; the rest is water, and the sum of the above components is 100%.

[0048]2) Mix water, water reducing agent, polyvinyl alcohol fiber, foaming agent, air-entraining agent, Portland cement and fly ash evenly and place in a mixer for slow stirring for 1-2 minutes, the speed of the mixer is 140± 5r / min, fully foaming for 2-3 minutes; then add the whole recycled aggregate into the mixer, stir slowly for 2-3min until the mixture is uniform, and get the whole recycled aggregate foam block material; finally put the whole recycled bone The materials used for the foam block are added to the mold of the mortar specimen at one time, poured into a mold, and prepared into a specimen of 40mm*40mm*160mm.

[0049] The fully recycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com