A method for preparing transparent calcium phosphate bioceramics by sintering under atmospheric pressure

A technology of transparent calcium phosphate and bioceramics, applied in the field of biomedical materials, can solve the problems of cumbersome sintering process, increase production cost, and large equipment investment, avoid decomposition and formation of impurity phases, meet mass production, and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

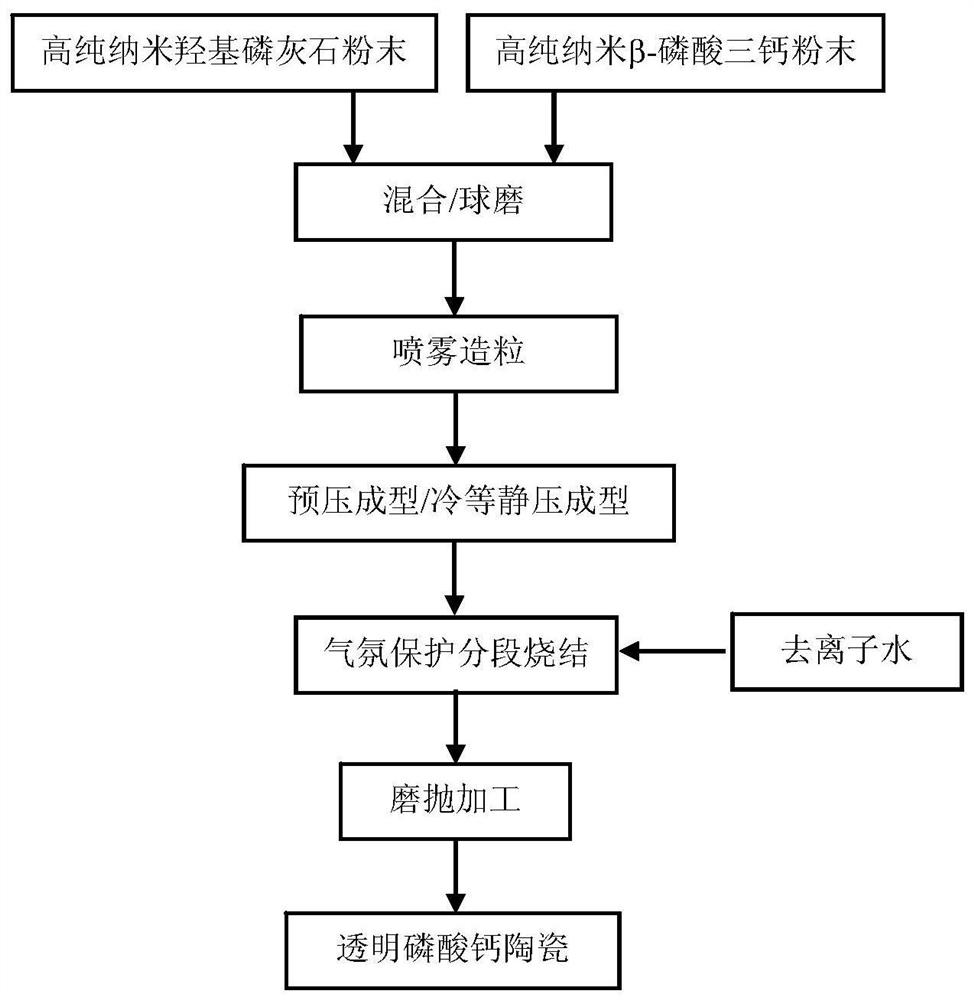

Method used

Image

Examples

Embodiment 1

[0050] (100wt% β-TCP+0wt% HA) transparent calcium phosphate bioceramic

[0051] Weigh and measure 100wt% high-purity nano-β-TCP powder and ball mill it for pulping and spray granulation, put the granulated powder into the mold, pre-press molding at 20MPa, and then cold isostatic pressing molding at 250MPa, and the molded billet The body was sintered in a box-type electric furnace. The sintering system is: 2°C / min to 550°C for 2 hours, then 10°C / min to 820°C for 5 hours, then 10°C / min to 950°C for 10 hours, and finally 2°C / min The temperature was lowered to 600° C. and then naturally cooled to room temperature to prepare a β-TCP single-phase transparent calcium phosphate bioceramic with an average grain size of 235 nm and a relative density of 99.5%. The light transmittance is 95%, and the bending strength is 178MP.

Embodiment 2

[0053] (0wt% β-TCP+100wt% HA) transparent calcium phosphate bioceramics

[0054] Weigh the measured 100wt% high-purity nano-HA powder and ball mill it for slurrying and spray granulation, put the granulated powder into the mold, pre-press molding at 30MPa and then cold isostatic pressing at 280MPa, place the green body after molding Sintered in a box-type electric furnace. The sintering system is: 2°C / min heating up to 550°C for 2 hours, then heating up to 700°C at a rate of 15°C / min. ℃ for 5 hours, then heated at 15℃ / min to 1250℃ for 1 hour, and finally cooled to 600℃ at 4℃ / min, stopped feeding deionized water, and cooled naturally to room temperature to prepare HA single-phase hyaluronic acid Calcium bioceramics, the average grain size is 156nm, and the relative density is 99.5%. The light transmittance is 92%, and the bending strength is 125MP.

Embodiment 3

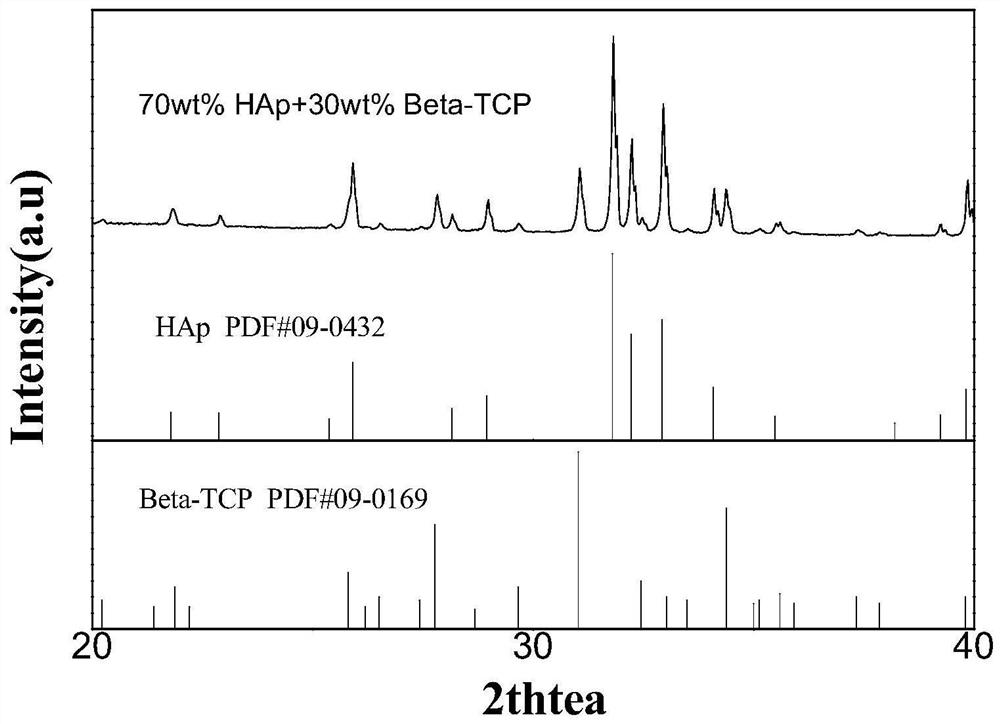

[0056] (10wt% β-TCP+90wt% HA) transparent calcium phosphate bioceramic

[0057] 90wt% high-purity nano-HA and 10wt% high-purity nano-β-TCP powder are mixed and ball milled for slurrying and spray granulation. The granulated powder is put into the mold, pre-pressed at 40MPa and then subjected to 300MPa cold isostatic Press molding, put the formed green body in a box-type electric furnace for sintering. The sintering system is: 2°C / min to 550°C for 2 hours, and then 20°C / min to 700°C, then pour deionized water at a rate of 4ml / min, and continue to heat up to 1000°C for 8 hours, and then Raise the temperature at a rate of 15 °C / min to 1250 °C for 4 hours, and finally cool down to 600 °C at a rate of 3 °C / min. Phase transparent calcium phosphate bioceramics, wherein the average grain size of the β-TCP phase is 360nm, the average grain size of the HA phase is 260nm, and the relative density is 99.5%. The light transmittance is 90%, and the bending strength is 135MP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com