Ablation-resistant phenolic cyanate prepreg and preparation method thereof

A technology of phenolic cyanate ester and prepreg, which is applied in the field of prepreg, which can solve the problems of prepreg prepared by hot melt method, high porosity of cured product, and difficulty in precise control of resin content, so as to achieve controllable curing process Good performance, high curing degree, good spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

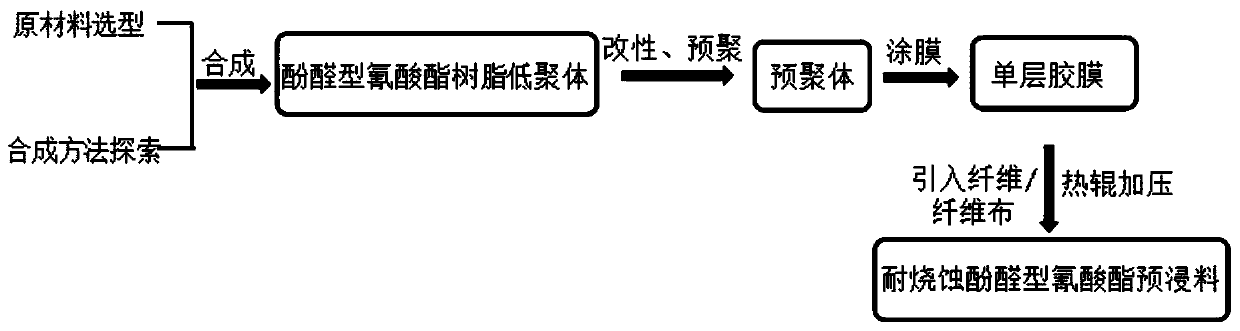

[0031] The preparation method of ablation-resistant phenolic cyanate ester prepreg of the present invention may further comprise the steps:

[0032] Step 1, synthesis of phenolic cyanate ester resin oligomer;

[0033] Step 2, modifying and prepolymerizing the phenolic cyanate resin oligomer to obtain a prepolymer;

[0034] Step 3, preparing a single-layer adhesive film with the prepolymer of step 2;

[0035] Step 4, introducing the unidirectional fiber or fiber cloth into the middle of the two single-layer adhesive films, and preparing the ablation-resistant phenolic cyanate prepreg by the hot-melt method.

[0036] In the above technical scheme, the process of step 1 is to dissolve the novolac resin and cyanogen bromide in an organic solvent, lower the temperature to below -10°C, and add the compound catalyst drop by drop under continuous stirring. The process ensures that the temperature is less than -5°C, and continues to stir for more than 2.5 hours to complete the reacti...

Embodiment 1

[0046] Step 1. Weigh 410.87g of novolac resin and 500g of cyanogen bromide, dissolve them in 2000mL of acetone, drop the temperature to -10°C in a dry ice bath, and add the compound catalyst dropwise under continuous stirring (the compound catalyst has a molar ratio of 3 : 1 mixture of triethylamine and DBU, the molar ratio of novolac resin to composite catalyst is 1:1.2), the interval between each drop is 10s, the whole dropping process ensures that the temperature is less than -5°C, continue to stir for 2.5h to make the reaction complete , using deionized water to wash repeatedly until the pH value is 6.5 to 7.0, rotary evaporation to remove water, and vacuum drying to obtain a phenolic cyanate resin oligomer.

[0047] Step 2. Weigh 500g of the phenolic cyanate ester resin oligomer prepared in step 1. After melting at 120°C, add 200ppm copper naphthenate and 0.5g cobalt acetylacetonate while stirring, pre-polymerize at 110°C for 80min, add 25g bis Phenol A-type epoxy resin E...

Embodiment 2

[0051] Step 1. Weigh 448.22g of novolac resin and 500g of cyanogen bromide, dissolve them in 1500mL of dichloromethane, drop the temperature to -15°C in a dry ice bath, and add the compound catalyst drop by drop under continuous stirring (the compound catalyst is molar ratio It is a mixture of triethylamine and DBU of 3:1, the molar ratio of novolac resin to compound catalyst is 1:1.2), the interval between each drop is 10s, the temperature of the whole dropping process is guaranteed to be less than -10°C, and the stirring is continued for 3h to make the reaction Completely, use deionized water to wash repeatedly until the pH value is 6.5 to 7.0, remove water by rotary evaporation, and dry in vacuum to obtain a phenolic cyanate resin oligomer.

[0052] Step 2. Weigh 500 g of the phenolic cyanate ester resin oligomer prepared in Step 1. After melting at 120 ° C, add 15 g of nonylphenol, 25 g of cobalt octanoate and 0.5 g of cobalt acetylacetonate while stirring, and pre-polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com