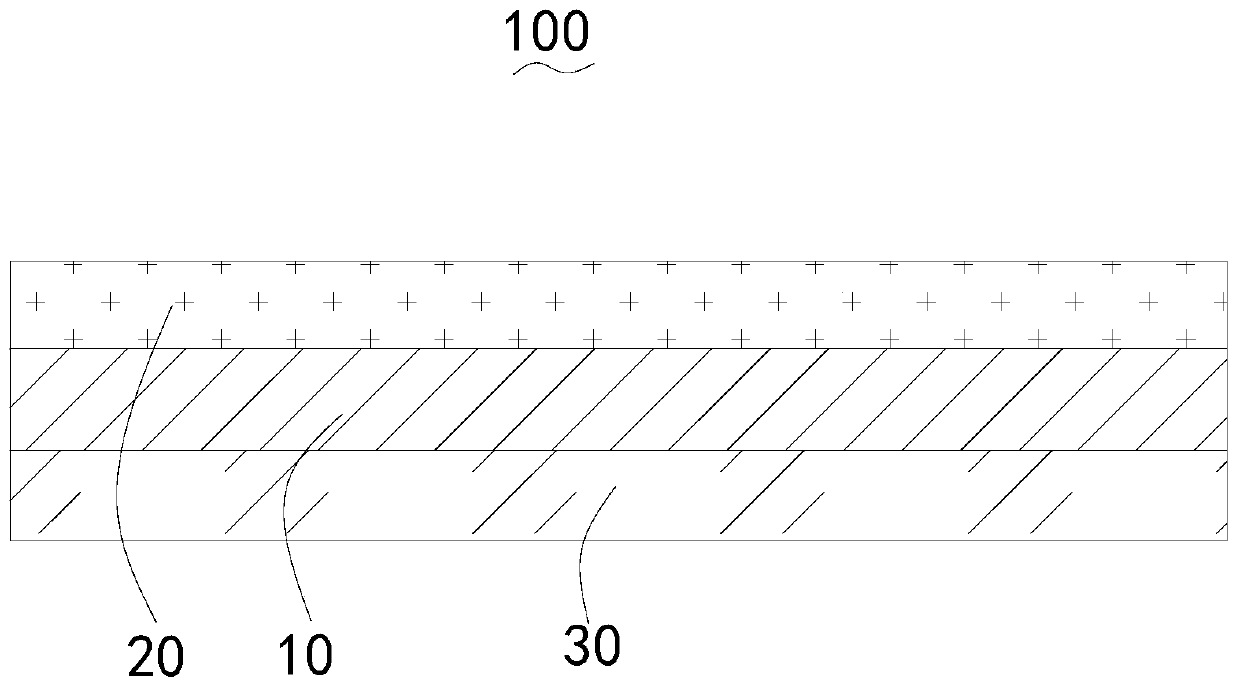

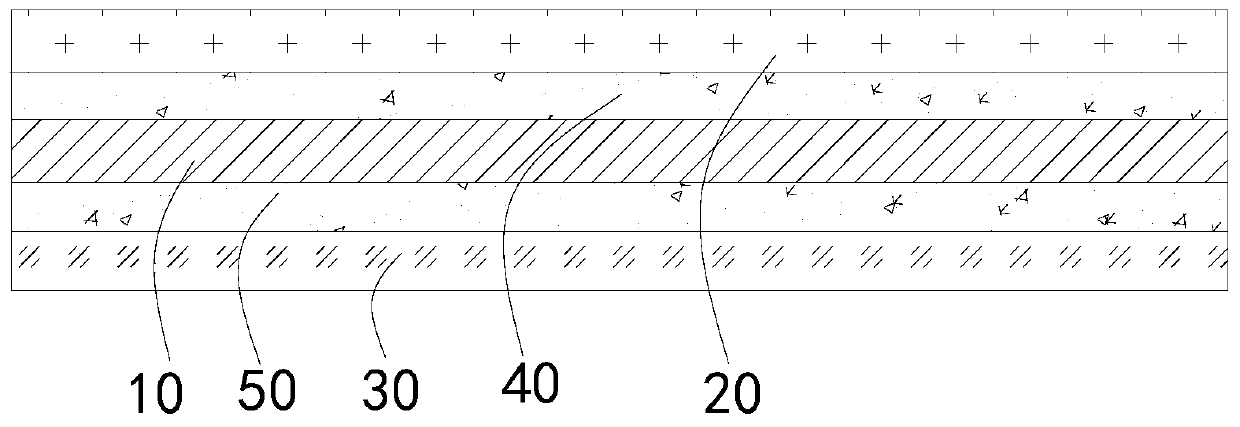

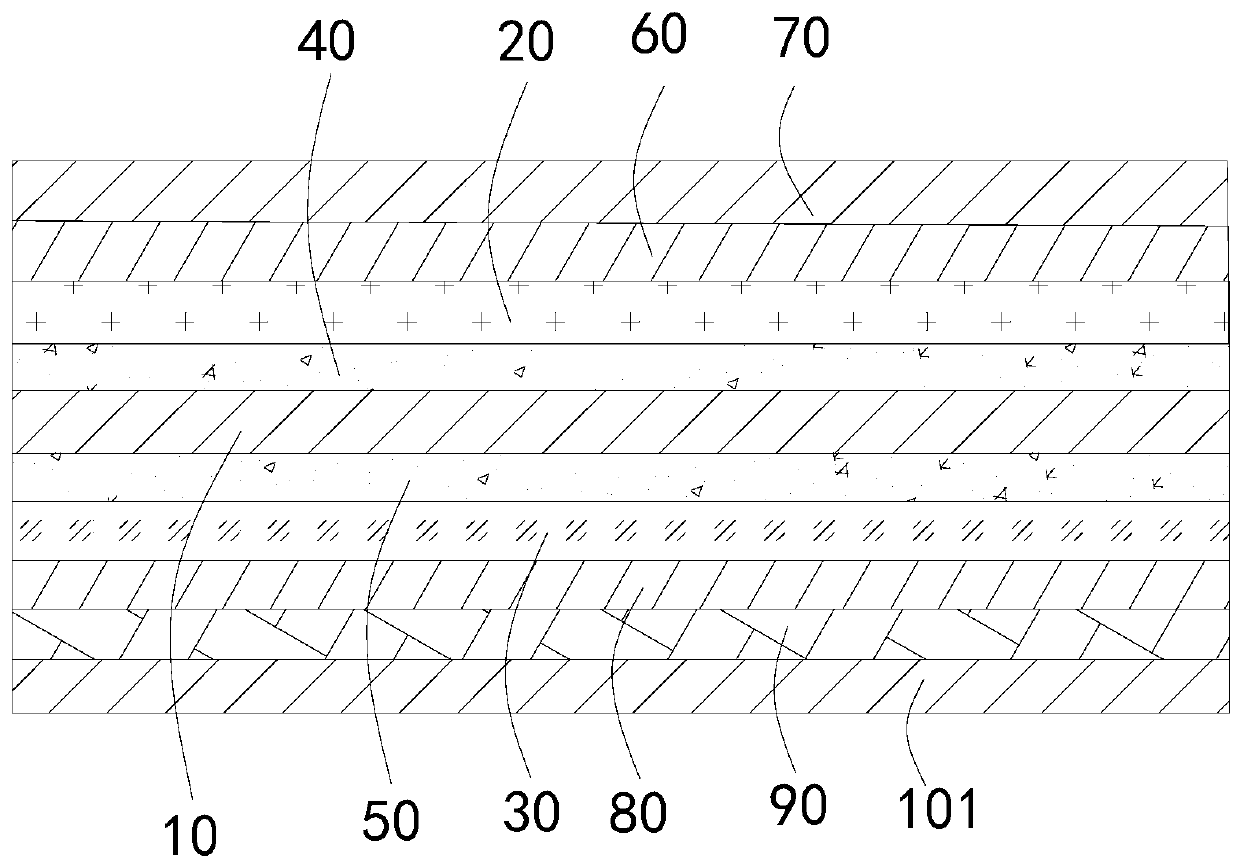

Curved screen protective film

A technology of protective film and curved screen, applied in film/sheet release coating, film/sheet adhesive, radiation absorbing paint, etc., can solve the problem that the effect of anti-blue light cannot meet the demand and cannot effectively resist blue light , easy to cause visual fatigue and other problems, to achieve rapid self-healing ability, eye care, strong buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the self-repairing material is as follows: the raw materials are dispersed and polymerized in a high-pressure reactor.

[0034] Specifically, the preparation method of the self-healing material is: mix the main raw materials and solvents except additives in a high-pressure reactor, stir for 15 minutes, slowly add cross-linking agents, catalysts and other additives and stir for 10 minutes, and then use vacuum pumping Principle The large amount of air bubbles generated during the stirring process in the coating solution is sucked away, and then left to defoam for 20 minutes to obtain a self-healing material. At this time, the self-healing material can be directly coated on the substrate 10 . This preparation method greatly reduces undesirable phenomena such as uneven coating surface and concave-convex points caused by the influence of bubbles in the coating liquid on coating, significantly improves the appearance of the coating, and can greatly im...

Embodiment 1

[0061] In this embodiment, the self-healing material includes the following components by weight: the self-healing material is made of the following components by weight: 32 parts of nano-silica, 35 parts of acrylic resin, 35 parts of modified polyisocyanate, hydroxyl 12 parts of magnesium silicate, 10 parts of hydroxyaluminum silicate, 1.5 parts of nano calcium carbonate, 3 parts of ethyl acetate, 10 parts of tert-butanol, 35 parts of butyl acetate, 12 parts of acetylacetone, 15 parts of active diluent, anti-settling 1 part of agent, 5 parts of adhesion promoter, 1.5 parts of dispersant and 0.8 part of corrosion inhibitor. The anti-blue light material is made of the following components by weight: 55 parts of azophenyl methacrylate, 22 parts of ethylisoacrylate phenyl 2H-benzotriazole, 12 parts of azo compounds, ethyl acetate 35 parts, 35 parts of butyl acetate and 5 parts of adhesion promoter.

Embodiment 2

[0063] In this embodiment, the self-healing material includes the following components by weight: the self-healing material is made of the following components by weight: 35 parts of nano-silica, 40 parts of acrylic resin, 40 parts of modified polyisocyanate, hydroxyl 15 parts of magnesium silicate, 12 parts of aluminum hydroxysilicate, 2 parts of nano-calcium carbonate, 5 parts of ethyl acetate, 15 parts of tert-butanol, 40 parts of butyl acetate, 15 parts of acetylacetone, 20 parts of reactive diluent, anti-settling 2 parts of agent, 8 parts of adhesion promoter, 2 parts of dispersant and 1.2 parts of anti-corrosion agent. The anti-blue light material is made of the following components by weight: 60 parts of azophenyl methacrylate, 25 parts of ethylisoacrylate phenyl 2H-benzotriazole, 15 parts of azo compounds, ethyl acetate 40 parts, 40 parts of butyl acetate and 8 parts of adhesion promoter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com