Piezoelectric composite film and preparation method thereof

A piezoelectric composite, composite thin film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. Affect the bonding process, high risk, complex process and other problems, to achieve the effect of reducing reverse pattern distortion, improving accuracy, and solving high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

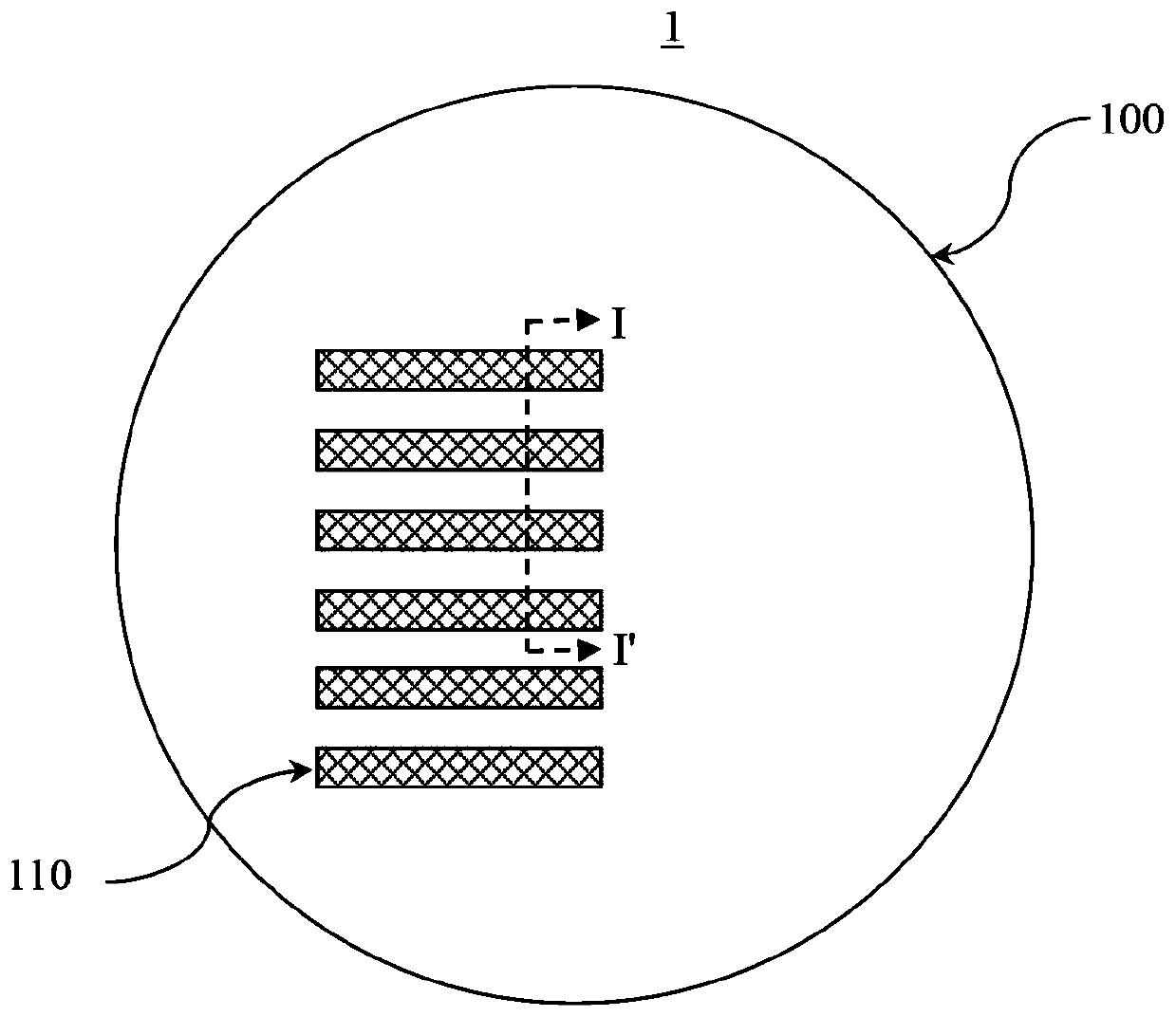

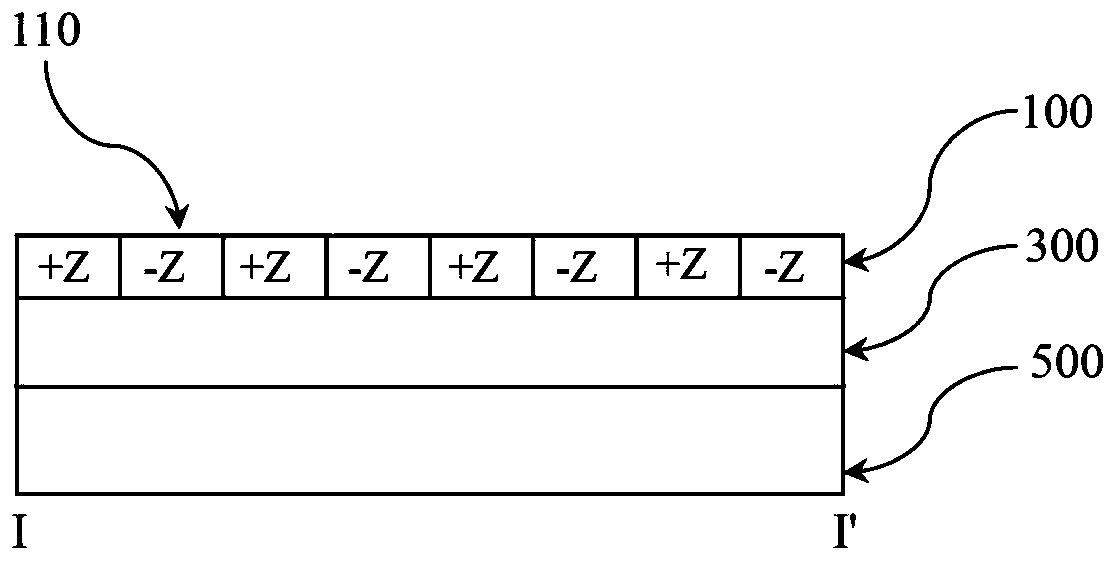

[0058] Firstly, a pre-piezoelectric composite film including a substrate, an isolation layer and a piezoelectric crystal film layer stacked in sequence is prepared. In the pre-piezoelectric composite film, the stacked structure of piezoelectric crystal film layer / isolation layer / substrate can be, for example, LT / SiO2 / Si with a thickness of 500nm / 3um / 400um respectively, wherein the polarization direction of the LT layer is + Z.

[0059] Next, a protective layer is formed on the piezoelectric crystal film layer by using a photoresist, and the protective layer is patterned through a photolithography process to obtain a pattern of the protective layer. The thickness of the protective layer is 3um-6um.

[0060] Next, an ion implantation process is performed on the region of the pre-piezoelectric composite thin film exposed by (or not covered by) the protective layer. Specifically, in this embodiment, the implanted ions may be He + , the implant energy can be about 150keV, and th...

Embodiment 2

[0064] Firstly, a pre-piezoelectric composite film including a substrate, an isolation layer and a piezoelectric crystal film layer stacked in sequence is prepared. In the pre-piezoelectric composite film, the stacked structure of piezoelectric crystal film layer / isolation layer / substrate can be, for example, LN / SiO2 / Si with a thickness of 500nm / 3um / 400um respectively, wherein the polarization direction of the LN layer is + Z.

[0065] Next, a silicon oxide layer is deposited on the piezoelectric crystal thin film layer to form a protection layer, and the protection layer is patterned through an etching process to obtain a protection layer pattern. The thickness of the protective layer is 3um-6um.

[0066] Next, an ion implantation process is performed on the region of the pre-piezoelectric composite thin film exposed by (or not covered by) the protective layer. Specifically, in this embodiment, the implanted ions may be He + , the implant energy can be about 150keV, and th...

Embodiment 3

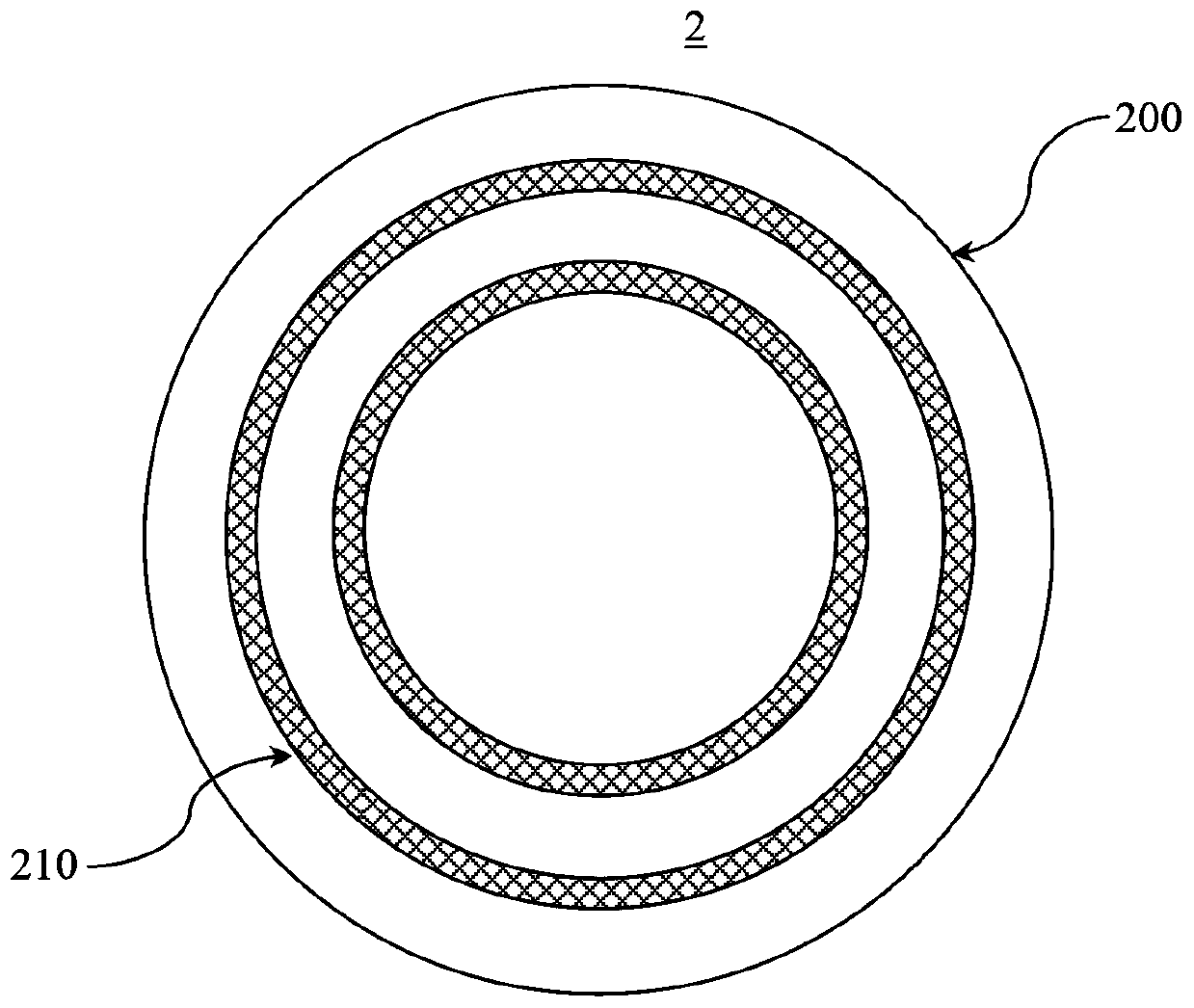

[0071] First, it can be based on Figure 4A The method described in to prepare the pre-piezoelectric composite film. In the pre-piezoelectric composite film, the stacked structure of piezoelectric crystal film layer / isolation layer / substrate can be, for example, LT / SiO2 / Si with a thickness of 300nm / 2um / 500um respectively, wherein the polarization direction of the LT layer is + Z.

[0072] Next, with the above Figure 4B and Figure 4C The difference is that in this embodiment, the process of forming the protective layer and the pattern of the protective layer is omitted, and the ion implantation process can be directly performed on the pre-piezoelectric composite film to reverse the polarization direction of the LT layer to -Z. Specifically, in this embodiment, the implanted ions can be H + , the implant energy can be about 100keV, and the implant dose can be about 8×10 16 ions / cm 2 .

[0073] Then, annealing is performed on the pre-piezoelectric composite thin film tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com