Premixed powder for delaying aging of brown rice bread, brown rice bread and processing method of brown rice bread

A technology of premixed flour and brown rice flour, which is applied in dough processing, baking, food science, etc., can solve the problems that brown rice food is difficult to be widely consumed and utilized, poor in quality and taste, easy to age and harden, etc., and achieve soluble dietary Increased fiber, increased water retention and water retention capacity, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

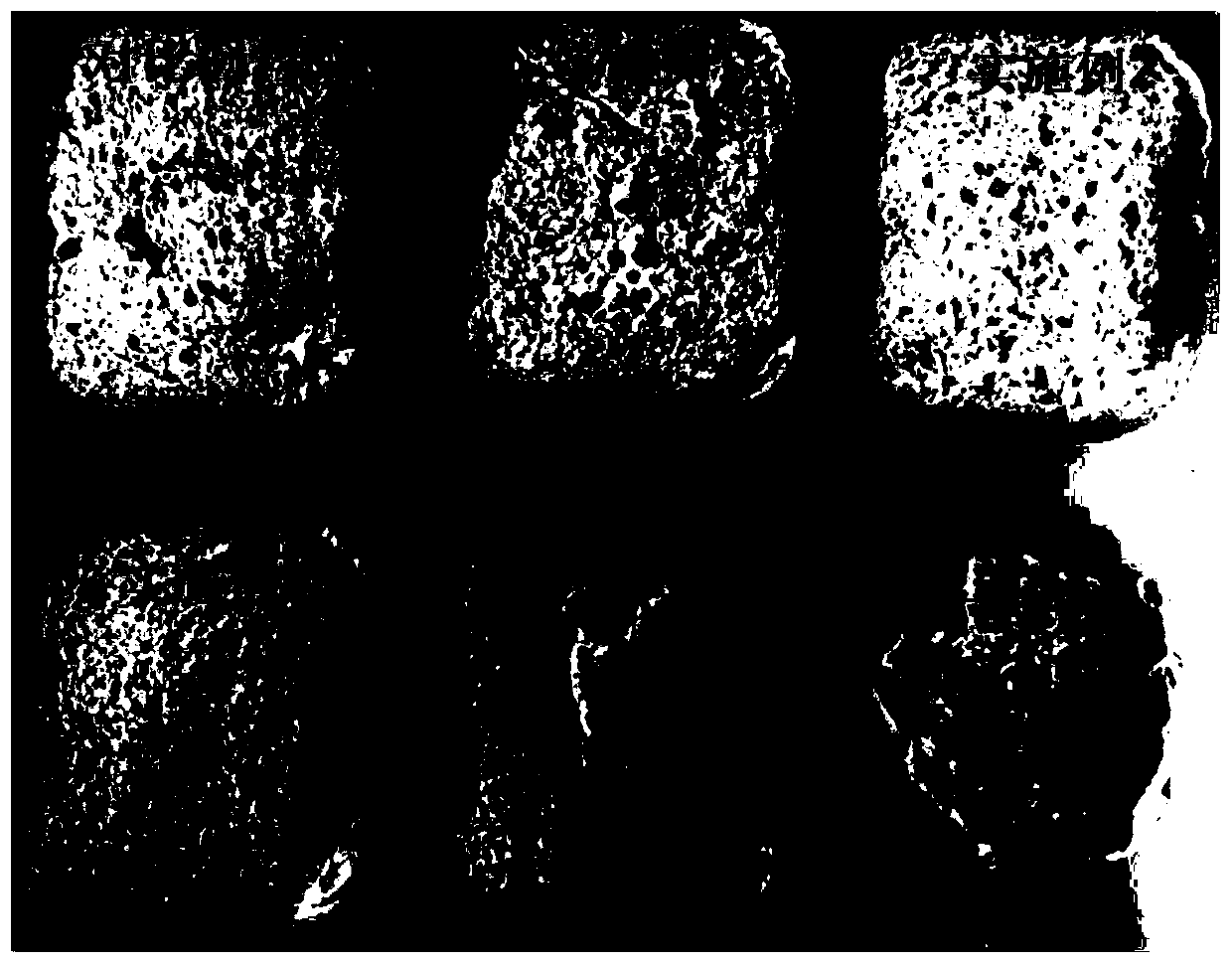

Image

Examples

Embodiment 1

[0024] (1) Extrusion and aging treatment of brown rice flour

[0025] The brown rice after pretreatment such as impurity removal is crushed through a 80-mesh sieve, put into an extruder for extrusion and aging, the extrusion conditions are: material moisture 20%, extrusion temperature 100°C, screw speed 200r / min, after cooling Crushed through 80 mesh sieve.

[0026] (2) Mix cooked brown rice flour and raw flour

[0027] Add the extruded and cured brown rice flour to the unextruded brown rice flour at a ratio of 10% to obtain the mixed brown rice flour.

[0028] (3) Preparation of premixed powder

[0029] Mix 80 parts of mixed brown rice flour, 0 parts of wheat flour, 20 parts of gluten powder, and 2 parts of yeast.

[0030] (4) Bread making

[0031] Take 200g of the above-mentioned brown rice bread premix powder, 8g of sugar, 4g of salt, 8g of milk powder, 10g of butter, and 190mL of water. Fully mix brown rice bread premix powder, sucrose, salt, milk powder and warm wate...

Embodiment 2

[0033] (1) Extrusion and aging treatment of brown rice flour

[0034] The brown rice after pretreatment such as impurity removal is crushed through a 80-mesh sieve, put into an extruder for extrusion and puffing, the extrusion conditions are: material moisture 25%, extrusion temperature 130°C, screw speed 250r / min, after cooling Crushed through 80 mesh sieve.

[0035] (2) Mixing of cooked brown rice flour and raw flour and particle fineness control

[0036] The extruded brown rice flour is added into the unextruded brown rice flour at a ratio of 25%, and the mixed brown rice flour is finely pulverized to a fineness of 100-150 mesh.

[0037] (3) Preparation of premixed powder

[0038] Mix 80 parts of mixed brown rice flour, 0 parts of wheat flour, 20 parts of gluten powder, and 2 parts of yeast.

[0039] (4) Bread making

[0040] Take 200g of the above-mentioned brown rice bread premix powder, 8g of sugar, 4g of salt, 8g of milk powder, 10g of butter, and 190mL of water. F...

Embodiment 3

[0042] (1) Extrusion and aging treatment of brown rice flour

[0043] The brown rice after pretreatment such as impurity removal is crushed through a 80-mesh sieve, put into an extruder for extrusion and puffing, the extrusion conditions are: material moisture 25%, extrusion temperature 180°C, screw speed 300r / min, after cooling Crushed through 80 mesh sieve.

[0044] (2) Mixing of cooked brown rice flour and raw flour and particle fineness control

[0045] The extruded brown rice flour is added into the unextruded brown rice flour at a ratio of 50%, and the mixed brown rice flour is finely pulverized to a fineness of 100-150 mesh.

[0046] (3) Preparation of premixed powder

[0047] 50 parts of mixed brown rice flour, 20 parts of wheat flour, 30 parts of gluten powder, 2 parts of yeast, 4 ppm of cellulase, 4 ppm of hemicellulase, and 8 ppm of xylanase were mixed evenly.

[0048] (4) Bread making

[0049]Take 200g of the above-mentioned brown rice bread premix powder, 8g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com