Copper ion chelated carboxyl functionalized magnetic bentonite as well as preparation method and application thereof

A carboxyl-functionalized, bentonite technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., to achieve the effects of low material cost, strong adsorption capacity, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

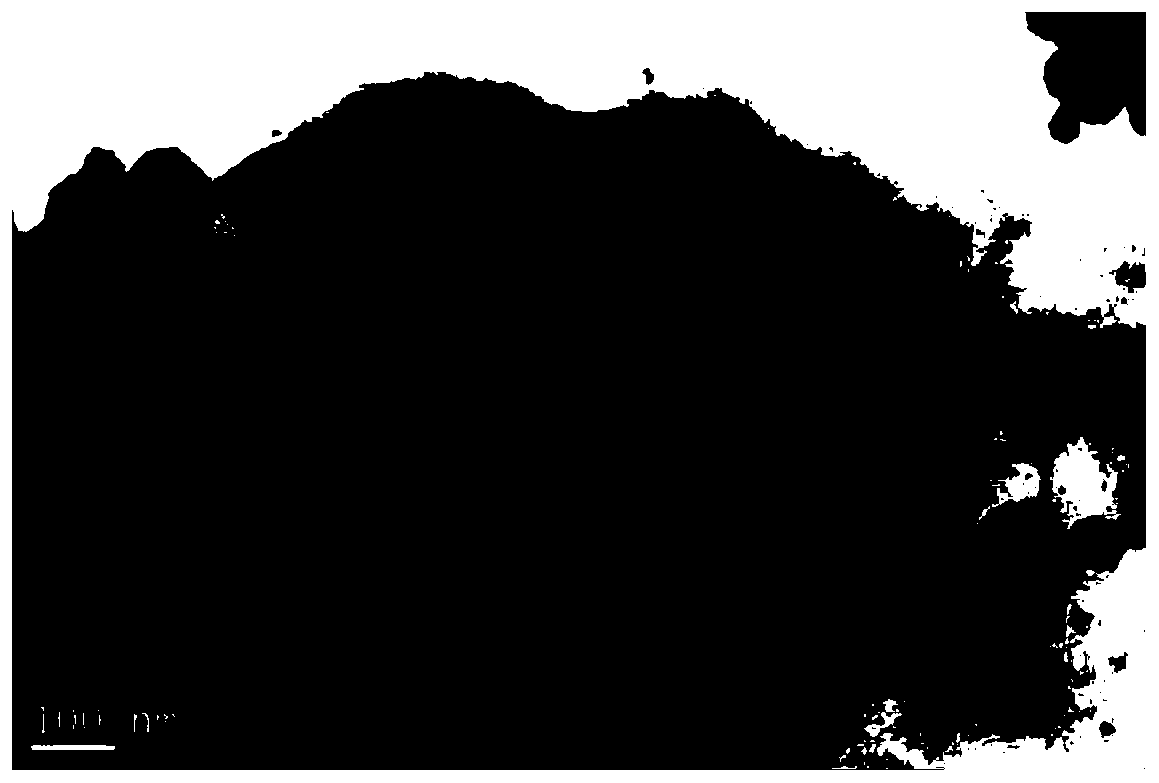

Image

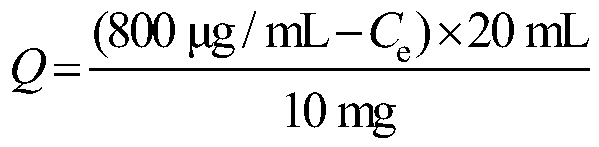

Examples

Embodiment 1

[0031] A preparation method of carboxyl functionalized magnetic bentonite chelated by copper ions, comprising the following steps:

[0032] Step 1. Weigh 0.06g of bentonite, 0.1g of ferric chloride, 0.5g of sodium acetate, 0.01g of sodium polyacrylate, 5.8mL of ethylene glycol and 10mL of diethylene glycol, and react at 170°C for 6 hours. After the reaction, The reaction product was washed and dried at 30°C for 3 hours to obtain carboxyl-functionalized magnetic bentonite;

[0033] Step 2. Weigh 0.05g of carboxy-functionalized magnetic bentonite, 0.15g of copper sulfate, and 10mL of ultrapure water, and react with mechanical stirring at room temperature for 30 minutes, wherein the stirring speed is 50r / min, to obtain a carboxyl-functionalized bentonite containing copper ions chelated. The reaction liquid of magnetic bentonite;

[0034] Step 3: Separating the solid polymer in the reaction solution after the reaction in Step 2 by applying an external magnetic field, washing the ...

Embodiment 2

[0045] A preparation method of carboxyl functionalized magnetic bentonite chelated by copper ions, comprising the following steps:

[0046] Step 1. Weigh 0.20g of bentonite, 0.30g of ferric chloride, 1g of sodium acetate, 0.03g of sodium polyacrylate, 7.5mL of ethylene glycol and 14mL of diethylene glycol, and react at 180°C for 8 hours. After the reaction, put The reaction product was washed and dried at 40°C for 4.5 hours to obtain carboxyl-functionalized magnetic bentonite;

[0047] Step 2: Weigh 0.15g of carboxyl-functionalized magnetic bentonite, 0.30g of copper sulfate, and 15mL of ultrapure water, and react with mechanical stirring at room temperature for 40 minutes, wherein the stirring speed is 120r / min, to obtain a carboxyl-functionalized bentonite containing copper ions chelated. The reaction liquid of magnetic bentonite;

[0048] Step 3: Separating the solid polymer in the reaction solution after the reaction in Step 2 by applying an external magnetic field, washi...

Embodiment 3

[0058] A preparation method of carboxyl functionalized magnetic bentonite chelated by copper ions, comprising the following steps:

[0059] Step 1. Weigh 0.45g of bentonite, 0.45g of ferric chloride, 1.5g of sodium acetate, 0.05g of sodium polyacrylate, 9mL of ethylene glycol and 19mL of diethylene glycol, and react at 190°C for 10 hours. After the reaction, put The reaction product was washed and dried at 45°C for 6 hours to obtain carboxyl-functionalized magnetic bentonite;

[0060] Step 2. Weigh 0.25g of carboxyl-functionalized magnetic bentonite, 0.45g of copper sulfate, and 20mL of ultrapure water, and react with mechanical stirring at room temperature for 50 minutes, wherein the stirring speed is 180r / min, to obtain a carboxyl-functionalized bentonite containing copper ions chelated. The reaction liquid of magnetic bentonite;

[0061] Step 3: Separating the solid polymer in the reaction solution after the reaction in Step 2 by applying an external magnetic field, washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com