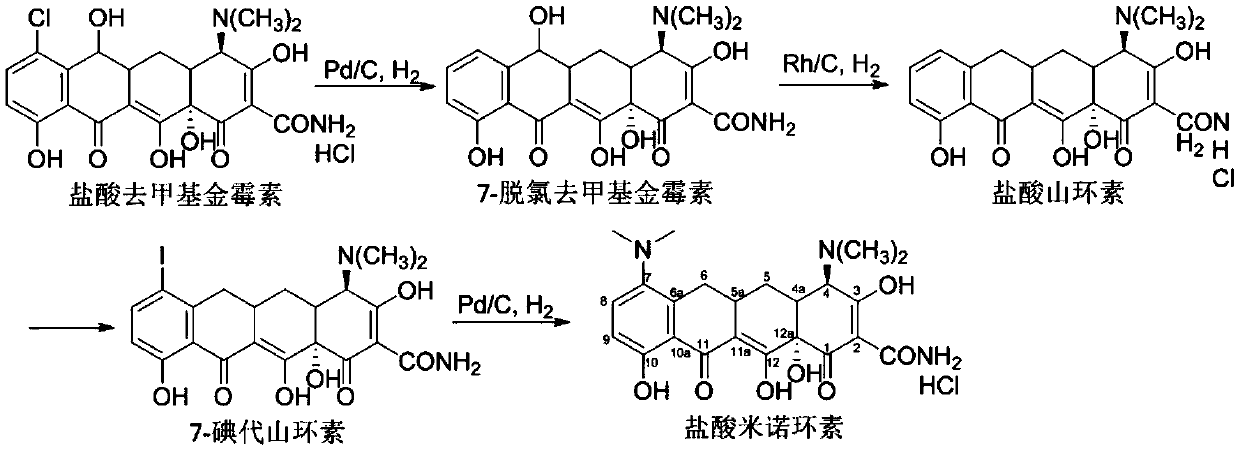

Preparation method of rhodium-carbon catalyst for synthesis of minocycline hydrochloride

A technology of minocycline hydrochloride and catalyst, which is applied in the field of preparation of rhodium carbon catalyst for the synthesis of minocycline hydrochloride, can solve the problems of poor repeatability, no involvement of rhodium carbon technology, low efficiency of rhodium metal colloid, etc., and achieve reduction of catalyst Activity, the preparation method is simple and easy to control, and the effect of ensuring the activity of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The rhodium carbon catalyst for the synthesis of minocycline hydrochloride of the present embodiment comprises a carrier and rhodium nanoparticles dispersed on the carrier, the carrier is powdered activated carbon treated with an aqueous solution of sodium hydroxide under microwave conditions, and the amount of rhodium in the catalyst is The mass percentage content is 5%.

[0033] The preparation method of the rhodium carbon catalyst of the present embodiment may further comprise the steps:

[0034] Step 1. The particle size is 200-400 mesh, and the specific surface area is about 900m 2 / g of wood charcoal, under microwave heating conditions, reflux treatment with 5% sodium hydroxide aqueous solution for 3h with a mass concentration, then wash with pure water until pH is 7.5, and dry to obtain pretreated activated carbon; the microwave-heated charcoal The temperature is 80°C;

[0035] Step 2, dissolving 1.0 g of rhodium-containing rhodium trichloride hydrate with pure...

Embodiment 2

[0042] The rhodium carbon catalyst for the synthesis of minocycline hydrochloride of the present embodiment comprises a carrier and rhodium nanoparticles dispersed on the carrier, the carrier is powdered activated carbon treated with an aqueous solution of sodium hydroxide under microwave conditions, and the amount of rhodium in the catalyst is The mass percentage content is 5%.

[0043] The preparation method of the rhodium carbon catalyst of the present embodiment may further comprise the steps:

[0044] Step 1. The particle size is 200-400 mesh, and the specific surface area is about 800m 2 / g of wood charcoal, under microwave heating conditions, reflux treatment of 3% sodium hydroxide aqueous solution with mass concentration for 2h, then wash with pure water until pH is 7.0, and dry to obtain pretreated activated carbon; The temperature is 90°C;

[0045] Step 2, dissolving 1.0 g of rhodium-containing rhodium trichloride hydrate with pure water at 100° C. to obtain soluti...

Embodiment 3

[0052] The rhodium carbon catalyst for the synthesis of minocycline hydrochloride of the present embodiment comprises a carrier and rhodium nanoparticles dispersed on the carrier, the carrier is powdered activated carbon treated with an aqueous solution of sodium hydroxide under microwave conditions, and the amount of rhodium in the catalyst is The mass percentage content is 5%.

[0053] The preparation method of the rhodium carbon catalyst of the present embodiment may further comprise the steps:

[0054] Step 1. The particle size is 200-400 mesh, and the specific surface area is about 1000m 2 / g wood charcoal, under microwave heating conditions, reflux treatment with 10% sodium hydroxide aqueous solution with mass concentration for 4h, then wash with pure water until pH is 8.0, and dry to obtain pretreated activated carbon; The temperature is 100°C;

[0055] Step 2. Dissolve 1.0 g of rhodium-containing rhodium trichloride hydrate with pure water at 80° C. to obtain solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com