Method for driving self-assembly coating to be rapidly prepared based on evaporation induced tension gradient

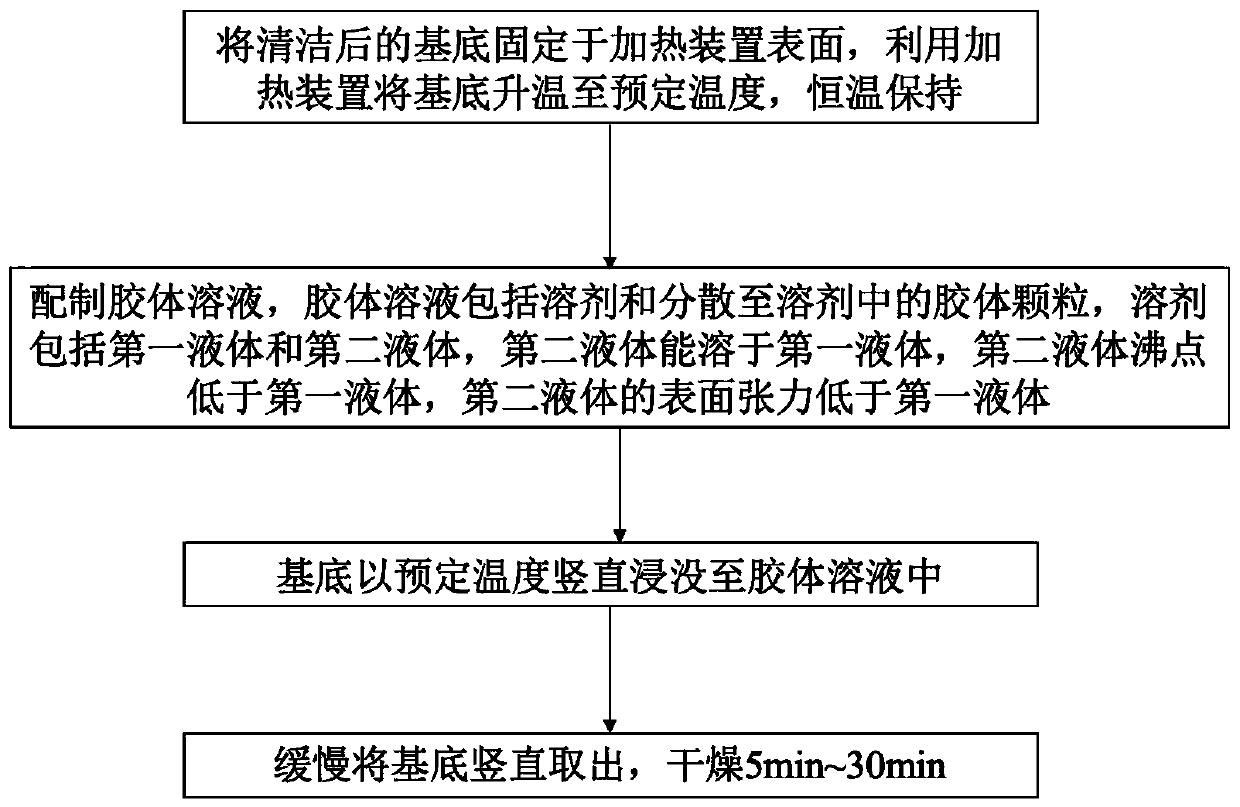

An evaporation-induced and self-assembly technology, which can be used in coatings, devices for coating liquids on surfaces, surface pretreatment, etc. It can solve the problems of chemical reagent residues, low pulling speed, complicated operation process, etc., and achieve fast preparation speed. , easy to control, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

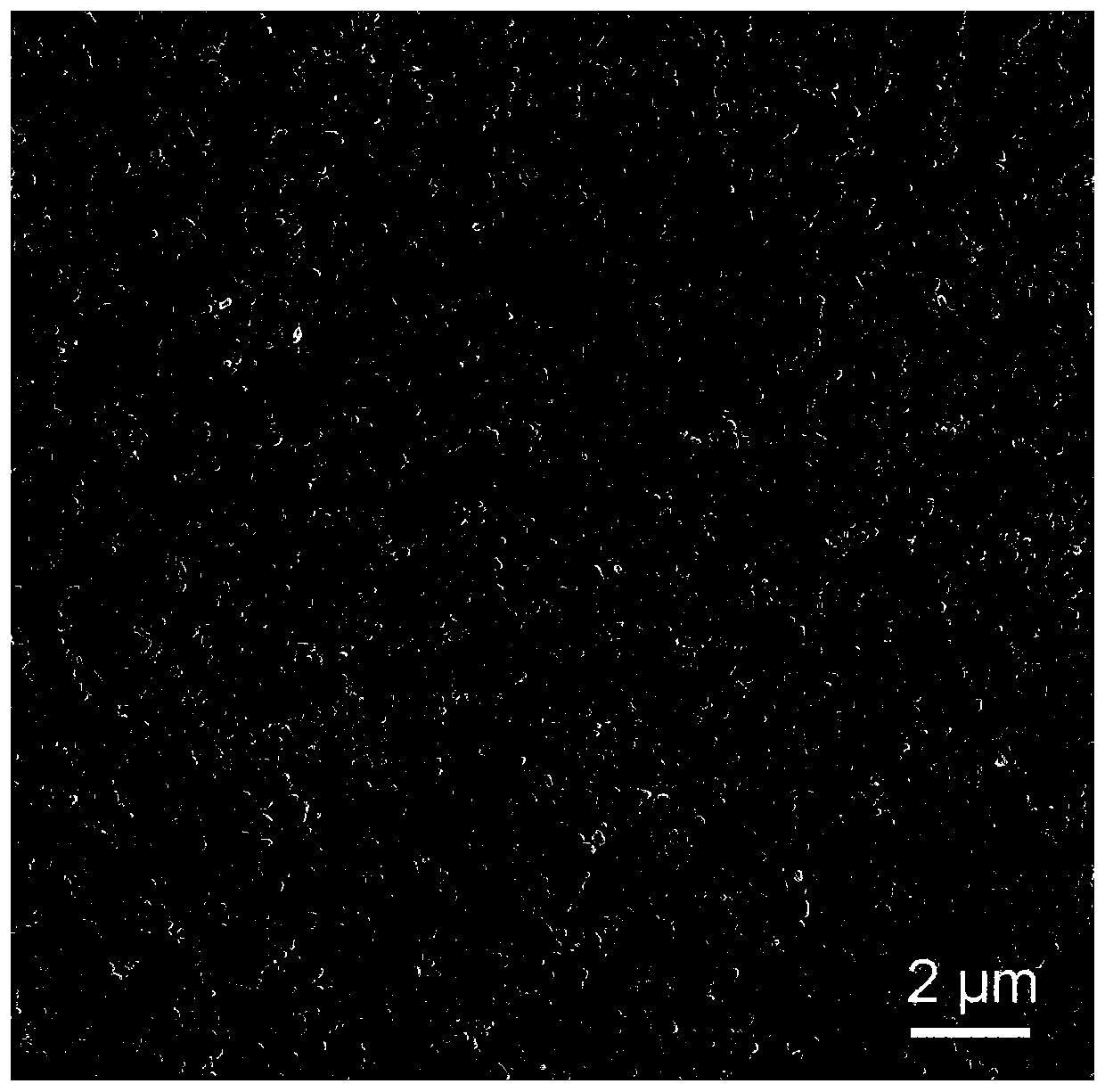

[0047] Using a silicon wafer as a substrate, the silicon wafer was cleaned with acetone, ethanol, and deionized water for 10 min in sequence, and dried with argon after cleaning.

[0048] Fix the substrate on the surface of the heating device, use the heating device to heat the substrate to 60°C and keep it at a constant temperature.

[0049] Prepare the colloidal solution, take water as the first liquid, ethanol as the second liquid, prepare a mixed solution of ethanol-water as a solvent, select a polystyrene (PS) dispersion with a mass fraction of 2.5%, and use a solvent to dissolve the PS dispersion Dilute to a dispersion liquid with a volume fraction of ethanol of 10% and a mass fraction of polystyrene particles of 2%, and ultrasonically mix for 5 minutes to obtain a colloidal solution.

[0050] Submerge the substrate vertically into the above colloid solution at a speed of 2 mm / s. Take out the substrate vertically at a speed of 0.2mm / s, and put it into a drying oven to d...

Embodiment 2

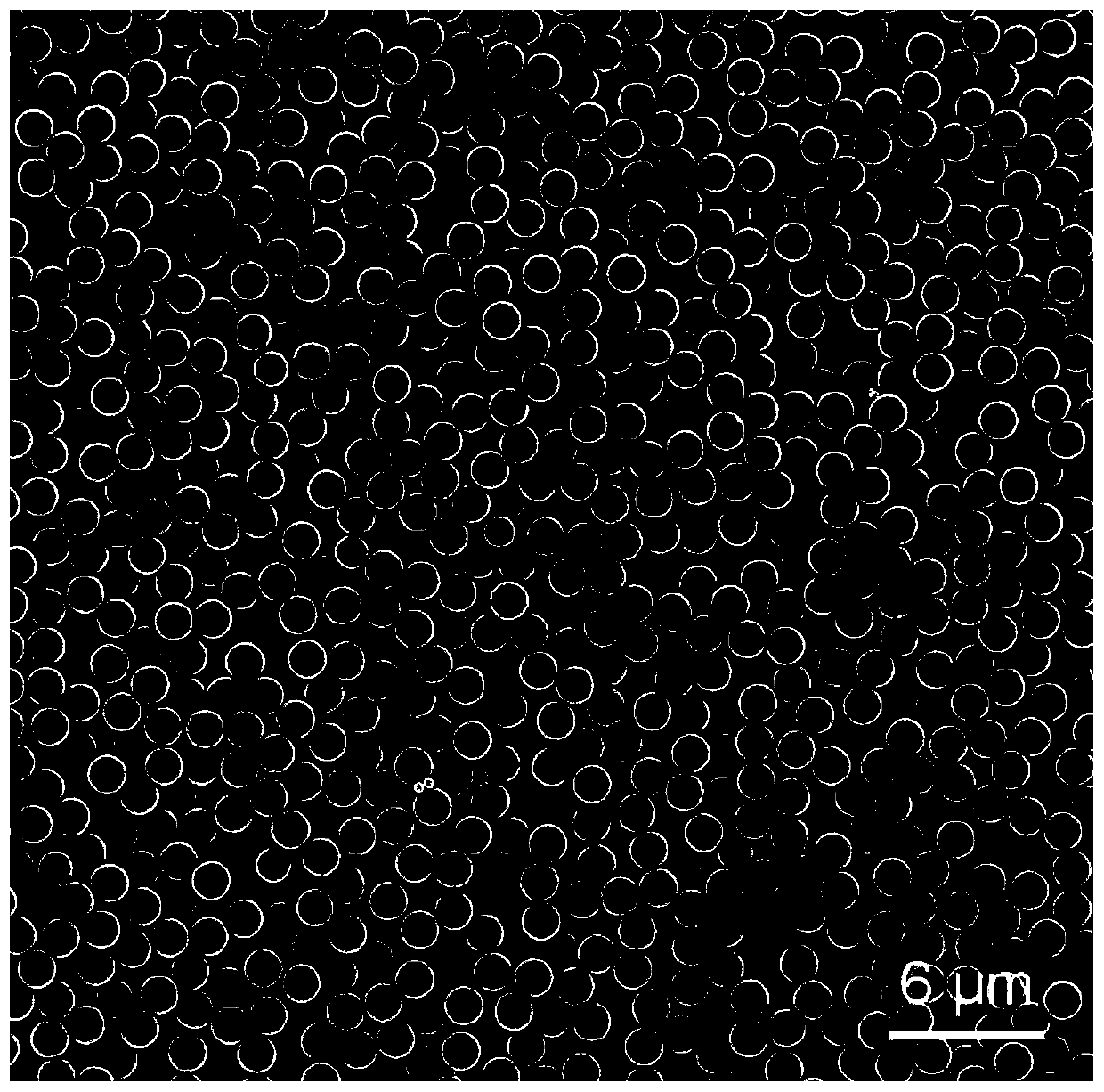

[0053] Using a silicon wafer as a substrate, the silicon wafer was cleaned with acetone, ethanol, and deionized water for 10 min in sequence, and dried with argon after cleaning.

[0054] Fix the substrate on the surface of the heating device, use the heating device to heat the substrate to 60°C and keep it at a constant temperature.

[0055] Prepare colloidal solution, take water as the first liquid, ethanol as the second liquid, prepare the mixed liquid that ethanol-water is formed as solvent, choose mass fraction to be 60% polytetrachlorethylene (PTFE) dispersion liquid, PTFE dispersion liquid is mixed with solvent Diluted to a dispersion liquid with a volume fraction of ethanol of 10% and a mass fraction of polytetrachloroethylene particles of 6%, and ultrasonically mixed for 5 minutes to obtain a colloidal solution.

[0056] Submerge the substrate vertically into the above colloid solution at a speed of 2 mm / s. Take out the substrate vertically at a speed of 0.2mm / s, and...

Embodiment 3

[0060] This embodiment is basically the same as the above-mentioned embodiment 2, except that the base is a metal mesh. Characterized by scanning electron microscopy, the individual wires in the metal mesh were covered with PTFE particles (such as Figure 4 , 5 shown). It shows that this method is applicable to curved surfaces and mesh surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com