Acid red skin stainless steel welding rod with high crack resistance and high porosity resistance

A stainless steel and coating technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem that the electrode is difficult to obtain high crack resistance and high porosity resistance, and achieve complete slag coverage and alloy. Reasonable ratio, strong porosity and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

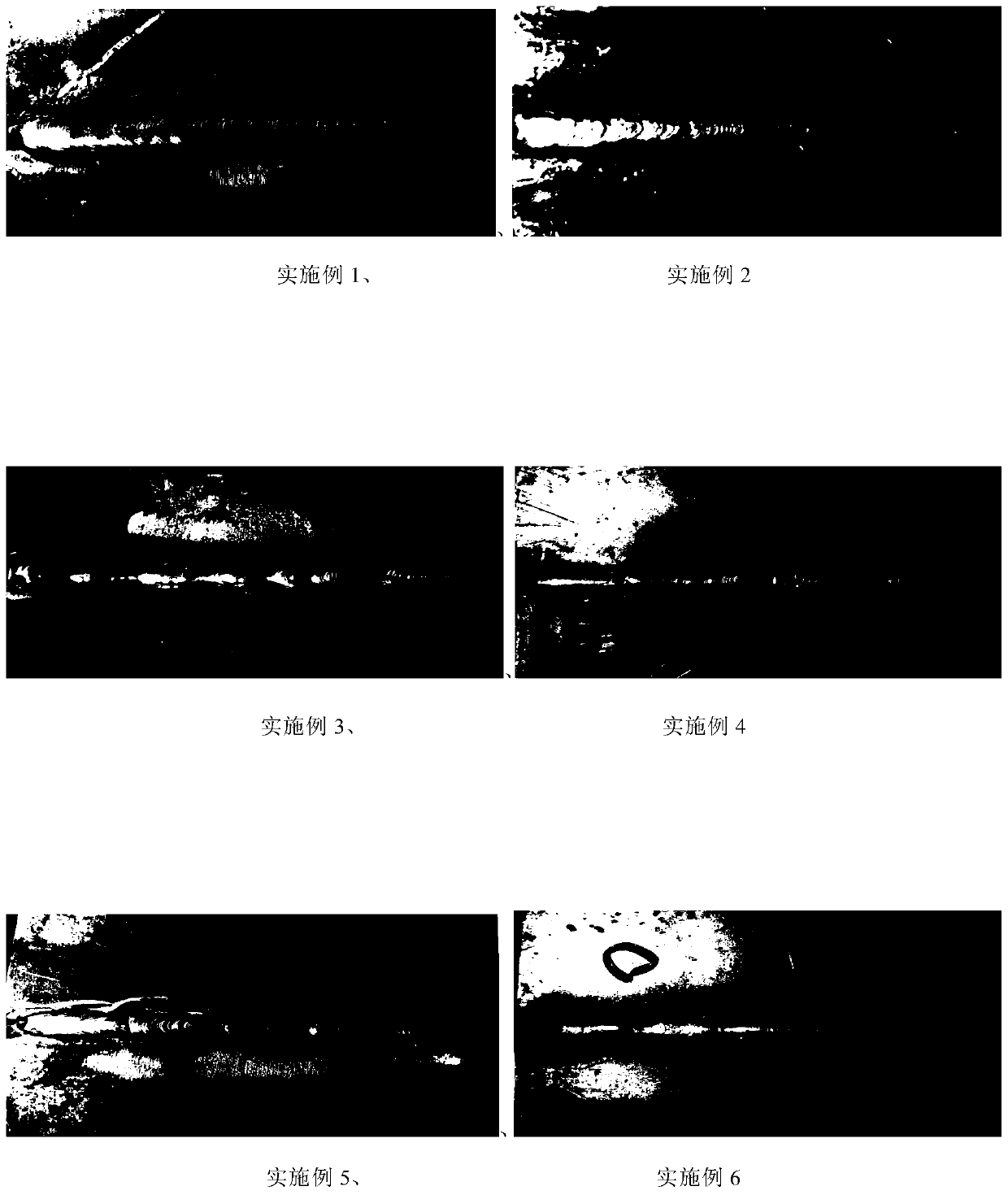

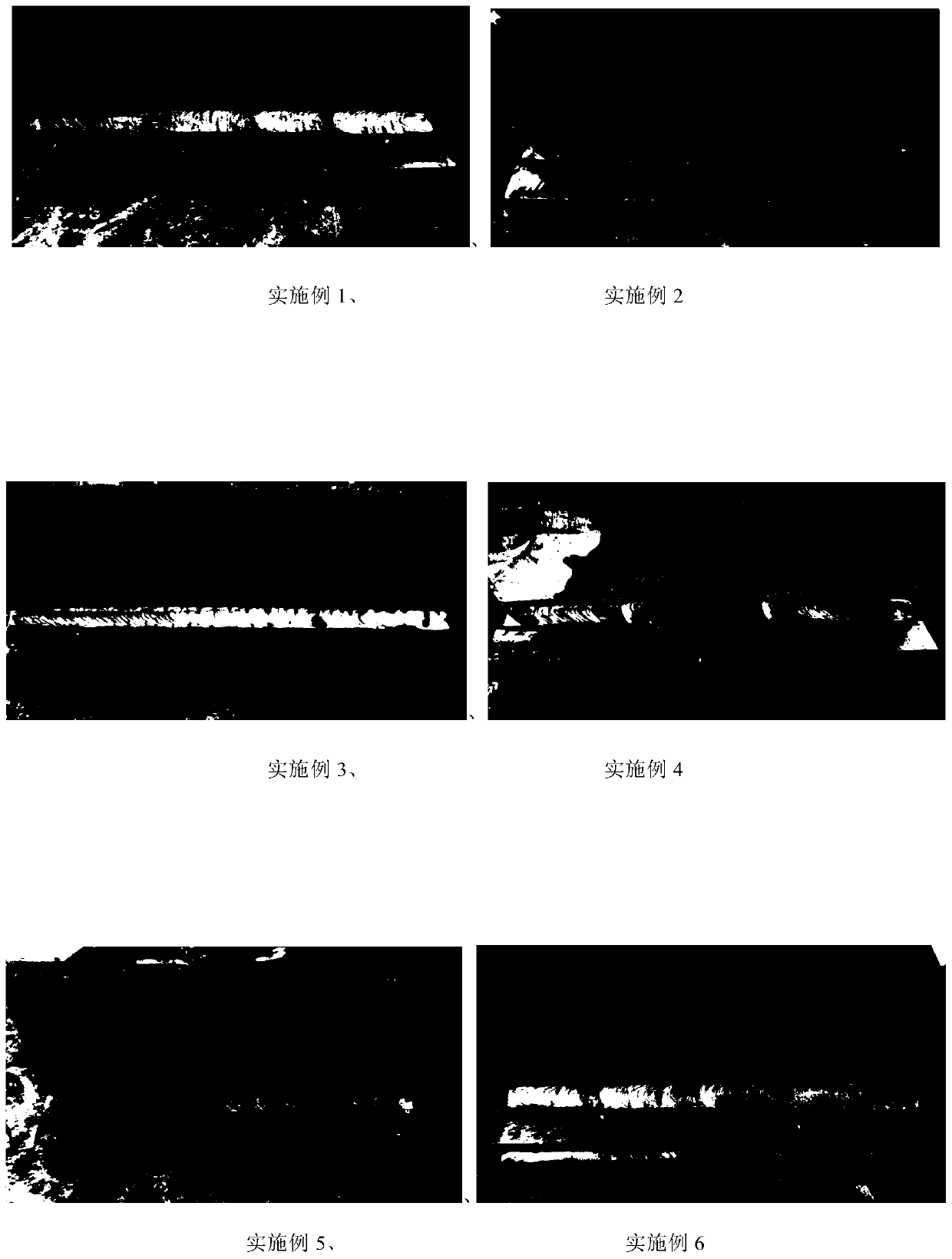

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of a kind of coated acidic stainless steel electrode

[0052] (a) In parts by weight, take 15 parts of marble, 10 parts of fluorite, 40 parts of rutile, 1 part of titanium dioxide, 10 parts of mica, 2 parts of ferrosilicon, 2 parts of metal chromium, 8 parts of ferrotitanium, and 4 parts of electrolytic manganese , 0.5 part of soda ash, mix each material powder evenly;

[0053] (b) For every 100 parts by weight of the mixed powder in step (a), take 23 parts by weight of potassium sodium water glass and add it to the dry powder and mix evenly. After drying at low temperature for 1 hour, and drying at high temperature, a stainless steel acid-coated electrode is obtained, which is recorded as E308-16.

[0054] Use the acid-coated stainless steel electrode E308-16 obtained in this example to carry out corresponding welding, and the welding current is 90-120A. Its welding process performance is excellent, no air holes appear in the welding on th...

Embodiment 2

[0055] Embodiment 2: Preparation of a kind of coated acidic stainless steel electrode

[0056] (a) In parts by weight, take 20 parts of marble, 7 parts of fluorite, 35 parts of rutile, 3 parts of titanium dioxide, 8 parts of mica, 3 parts of ferrosilicon, 10 parts of metal chromium, 4 parts of ferro-titanium, and 5 parts of electrolytic manganese , 0.5 part of soda ash, mix each material powder evenly;

[0057] (b) For every 100 parts by weight of the mixed powder in step (a), take 22 parts by weight of potassium sodium water glass and add it to the dry powder and mix evenly. After drying at a low temperature for 1 hour, and then drying at a high temperature, a stainless steel acid-coated electrode is obtained, which is designated as E308L-16.

[0058] Use the acidic stainless steel electrode E308L-16 with the coating obtained in this embodiment to carry out corresponding welding, and the welding current is 120-160A. Its welding process performance is excellent, no porosity ...

Embodiment 3

[0059] Embodiment 3: Preparation of a kind of coated acidic stainless steel electrode

[0060] (a) In parts by weight, take 25 parts of marble, 8 parts of fluorite, 30 parts of rutile, 4 parts of titanium dioxide, 7 parts of mica, 4 parts of ferrosilicon, 5 parts of metal chromium, 5 parts of ferro-titanium, and 7 parts of electrolytic manganese , 1 part of soda ash, and mix the powders of each material evenly;

[0061] (b) For every 100 parts by weight of the mixed powder in step (a), take 24 parts by weight of potassium sodium water glass and add it to the dry powder and mix evenly. After drying at low temperature for 1 hour, and drying at high temperature, a stainless steel acid-coated electrode is obtained, which is recorded as E316-16.

[0062] Use the acidic stainless steel electrode E316-16 with the coating obtained in this embodiment to carry out corresponding welding, and the welding current is 150-200A. Its welding process performance is excellent, no air holes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com