Gypsum die manufacturing method and method for utilizing gypsum die manufacturing method for manufacturing fusion quartz ceramic antenna cover

A gypsum mold and manufacturing method technology, which is applied in the direction of die-casting molds, manufacturing tools, ceramic molding machines, etc., can solve the problem of low grouting pressure of only 0.1-0.3MPa, etc., achieve non-polluting raw material sources, and accelerate grouting The effect of improving molding speed and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

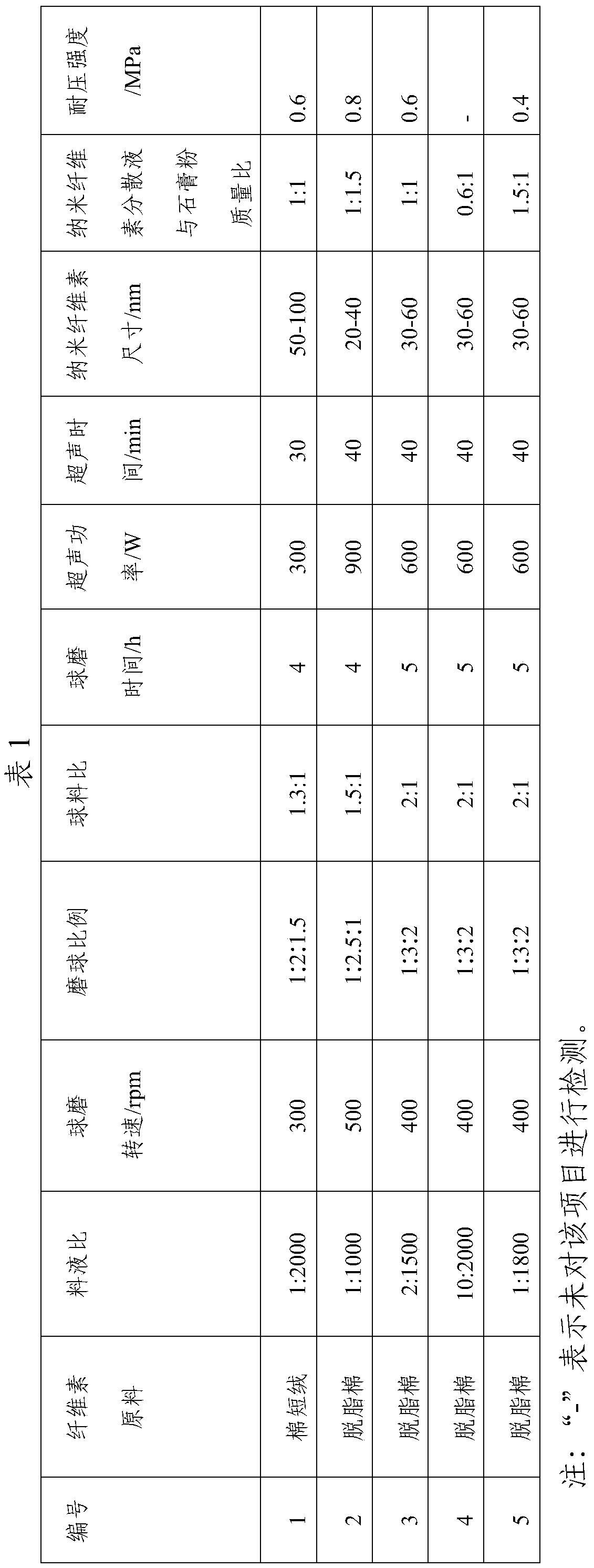

Embodiment 1

[0058] S1. Preparation of nanocellulose: Add cotton linters and 2wt% sulfuric acid aqueous solution into the ball mill tank, add large, medium and small grinding balls, the diameters of the large, medium and small grinding balls are 30mm, 20mm, and 10mm respectively, and set the ball mill speed to 300rpm After ball milling for 4 hours, the dispersion 1 was obtained after being washed with distilled water for 5 times; the mass ratio of cotton linters and aqueous solution was 1:2000, the ratio of balls to materials was 1.3:1, and the ratio of large, medium and small balls was 1:2:1.5; Liquid 1 was placed in a beaker, the ultrasonic probe was placed in the beaker 1.5 cm below the liquid surface, the ultrasonic power was set to 300 W, and the nanocellulose dispersion 2 was obtained by ultrasonication for 30 minutes.

[0059] S2, preparation of gypsum mold: add gypsum powder and nano-cellulose dispersion 2 into the mixing tank, the mass ratio of nano-cellulose dispersion 2 and gypsu...

Embodiment 2

[0063] S1, the preparation of nanocellulose: add absorbent cotton and 2wt% sulfuric acid aqueous solution in the ball mill tank, add large, medium and small grinding balls, the diameters of the large, medium and small grinding balls are respectively 30mm, 20mm, 10mm, set the ball mill speed to 500rpm, ball mill Dispersion 1 was obtained after 4 hours of washing with distilled water for 5 times. Among them, the mass ratio of absorbent cotton and aqueous solution is 1:1000, the ratio of balls to materials is 1.5:1, and the ratio of large, medium and small balls is 1:2.5:1; put the dispersion 1 in a beaker, and place the ultrasonic probe under the liquid surface in the beaker 1.5cm, set the ultrasonic power to 900W, and ultrasonically for 40min to obtain nanocellulose dispersion 2. The morphology of the prepared nanocellulose is shown in figure 1 .

[0064] S2, preparation of gypsum mold: add gypsum powder and nanocellulose dispersion 2 in the mixing tank, the mass ratio of nan...

Embodiment 3

[0068] S1, the preparation of nanocellulose: add absorbent cotton and 2wt% sulfuric acid aqueous solution in the ball mill tank, add large, medium and small grinding balls, the diameters of the large, medium and small grinding balls are respectively 30mm, 20mm, 10mm, set the ball mill speed to 400rpm, ball mill Dispersion 1 was obtained after 5 hours of washing with distilled water. Among them, the mass ratio of absorbent cotton and aqueous solution is 2:1500, the ratio of balls to materials is 2:1, and the ratio of large, medium and small balls is 1:3:2; put the dispersion 1 in a beaker, and place the ultrasonic probe under the liquid surface in the beaker 1.5cm, set the ultrasonic power to 600W, and ultrasonically for 40min to obtain nanocellulose dispersion 2.

[0069] S2, preparation of gypsum mould: add gypsum powder and nanocellulose dispersion 2 into the mixing tank, the mass ratio of nanocellulose dispersion 2 and gypsum powder is 1:1, stir for 5min and then pour into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com