Oily sludge innocent treatment system and treatment method thereof

A technology of harmless treatment and treatment method, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of complex extractant components, increased treatment costs, and complex preparation processes. , to achieve the effects of moderate process conditions, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

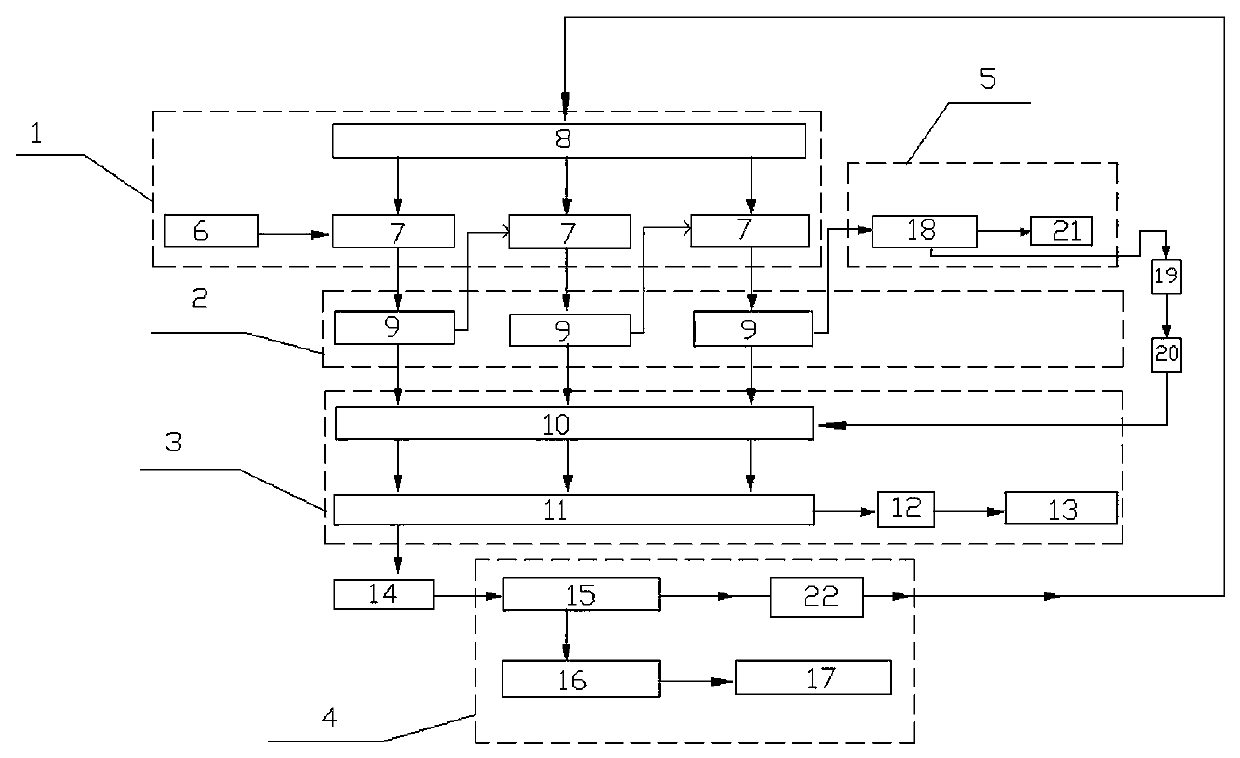

[0057] see figure 1 , The feeding method in this embodiment 1 is continuous feeding, and the number of stirring tanks 7 is three. A harmless treatment system for oily sludge, comprising a vacuum drying system 5 , a feed mixing system 1 connected in sequence, a solid-liquid two-phase separation system 2 , an oil-water separation system 3 , and an extraction agent recovery system 4 . The solid-liquid two-phase separation system 2 communicates with the vacuum drying system 5 . The vacuum drying system 5 communicates with the oil-water separation system 3 . Extractant recovery system 4 communicates with feed stirring system 1 .

[0058] Wherein, the feed stirring system 1 includes an oily sludge inlet 6 , three stirring tanks 7 , and an extraction agent storage tank 8 . The extractant storage tank 8 communicates with each stirring tank 7 .

[0059] Wherein, the solid-liquid two-phase separation system 2 includes three centrifuges 9 .

[0060] Such as figure 1 , in this embod...

Embodiment 2

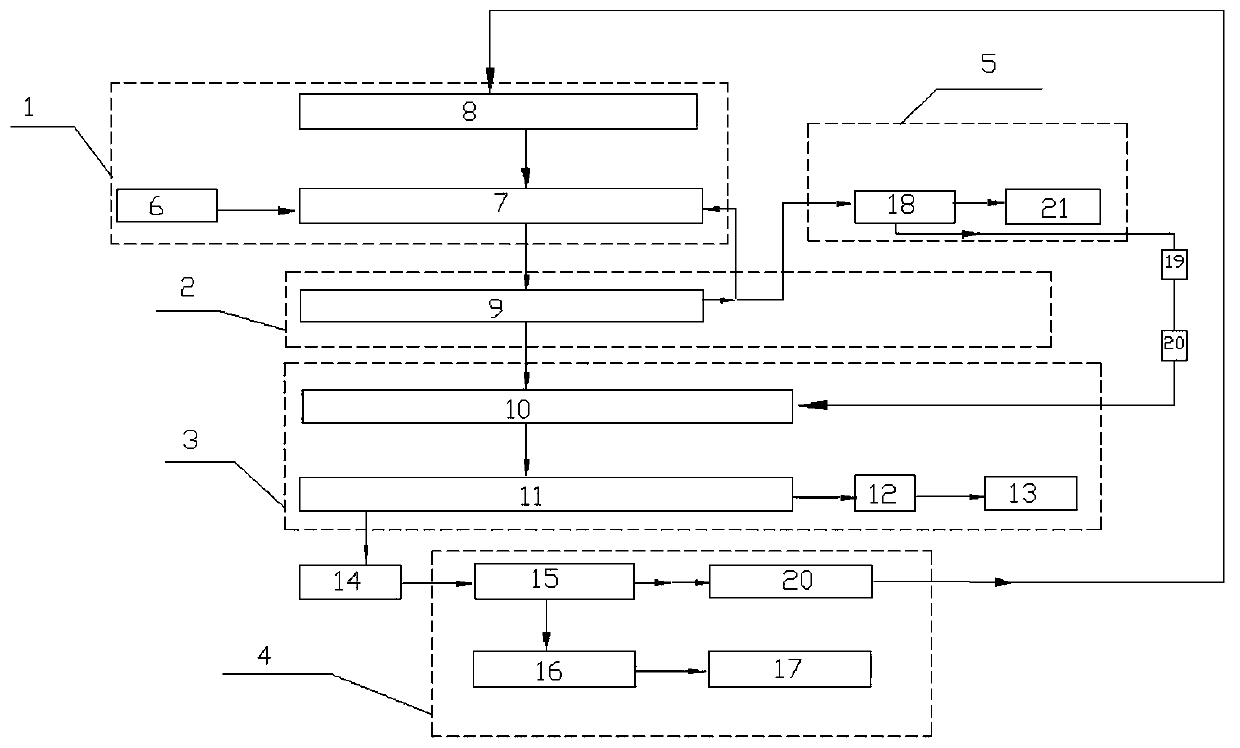

[0084] see figure 2 , the present embodiment 2 is intermittent feeding, and the number of stirring tank 7 is one. A harmless treatment system for oily sludge, comprising a vacuum drying system 5 , a feed mixing system 1 connected in sequence, a solid-liquid two-phase separation system 2 , an oil-water separation system 3 , and an extraction agent recovery system 4 . The solid-liquid two-phase separation system 2 communicates with the vacuum drying system 5 . The vacuum drying system 5 communicates with the oil-water separation system 3 . Extractant recovery system 4 communicates with feed stirring system 1 .

[0085] Wherein, the feeding stirring system 1 includes an oily sludge inlet 6, a stirring tank 7, and an extraction agent storage tank 8, and the extraction agent storage tank 8 and the stirring tank 7 are all connected.

[0086] Wherein, the solid-liquid two-phase separation system 2 includes a centrifuge 9 .

[0087] Specifically, the stirring tank 7 is connected ...

Embodiment 3

[0115] In Example 3, the oily sludge harmless treatment system and treatment method in Example 1 were adopted, and a petrochemical company cleared tank #1 oil sludge (oil content 27.8%, water content 19.3%) was used as raw material for the test, and the extractant The components include n-butyl acetate and water, wherein the volume ratio of n-butyl acetate to water is 1:0.5, mixed and stirred evenly. The extractant and the oily sludge in the first stirring tank 7 were mixed and stirred evenly according to the mass ratio of 1:1, and implemented according to the treatment method in Example 1. After the treatment, the oil content of the sludge was 0.24%, and the oil removal rate was 99.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com