Bamboo charcoal memory foam and preparation method thereof

A technology of memory foam and bamboo charcoal, which is applied in the field of memory foam materials and can solve the problems of not being able to purify harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

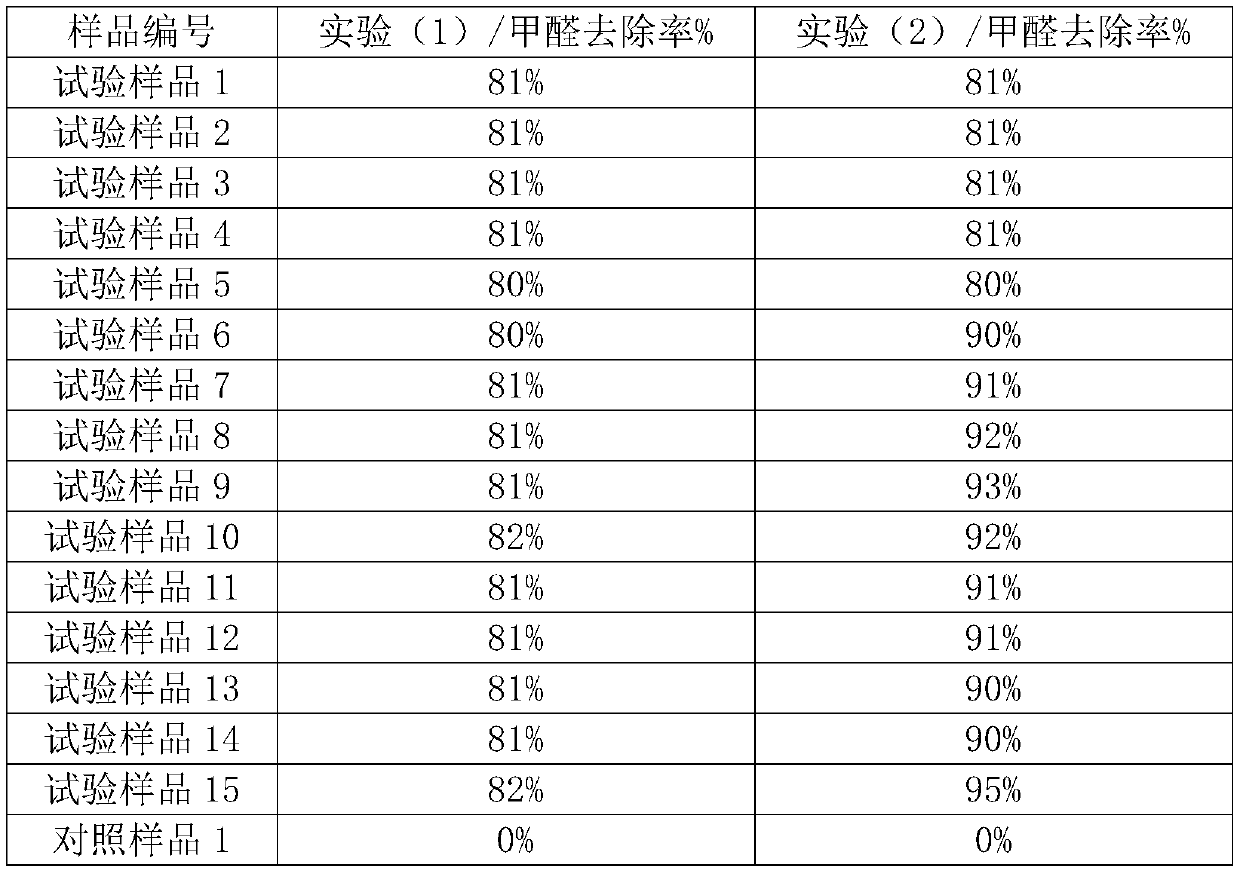

Examples

Embodiment 1

[0048] Embodiment 1: a kind of bamboo charcoal memory cotton, each component of its raw material and corresponding weight parts thereof are as shown in table 1, and prepare and obtain by following steps:

[0049]Step 1: Mix polyoxyethylene triol, polyether polyol, cell opener, silicone oil, stannous octoate, bamboo charcoal powder, and bamboo charcoal fiber in corresponding parts by weight, and stir evenly to obtain mixture A;

[0050] Step 2, adding toluene diisocyanate into mixture A, stirring evenly to obtain mixture B;

[0051] Step 3: pour mixture B into an aluminum mold, then place the aluminum mold in a constant temperature oven at 60°C, heat it for 7 minutes, and mature it into shape;

[0052] Step 4: Take out the aluminum mold from the oven, remove the mold, place the formed bamboo charcoal memory foam embryos indoors, mature for 24 hours, and ventilate naturally for 5 hours to obtain the bamboo charcoal memory foam.

[0053] Among them, the cell opener is KY-1206 pu...

Embodiment 2-5

[0054] Embodiment 2-5: a kind of bamboo charcoal memory foam, the difference with embodiment 1 is that its raw material components and corresponding parts by weight are as shown in table 1.

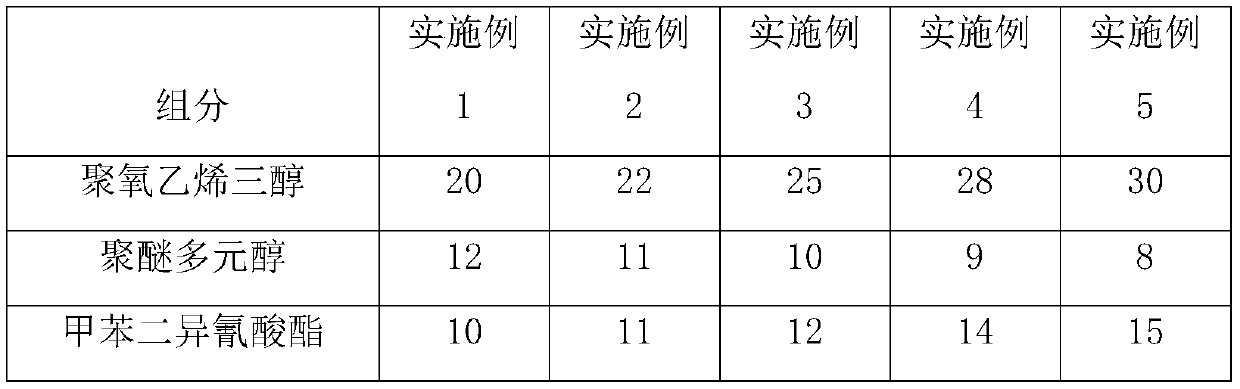

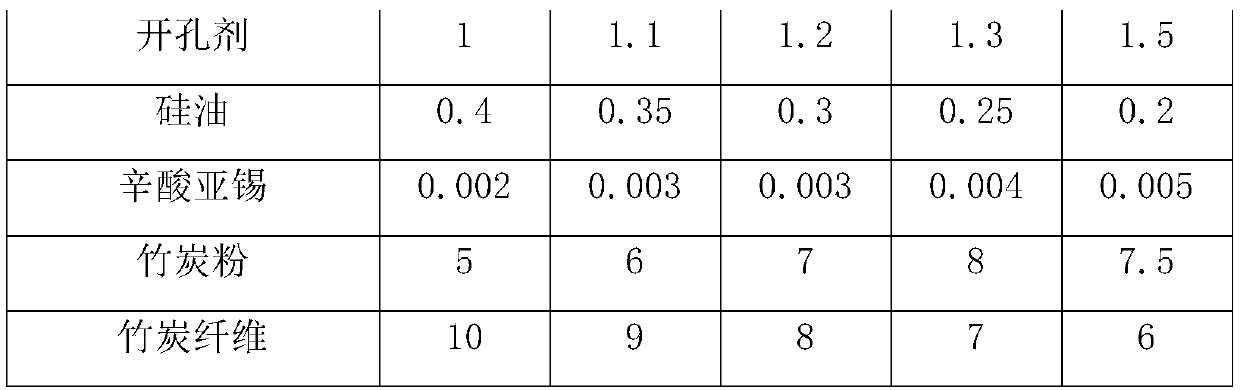

[0055] Each component of raw material and parts by weight thereof in table 1 embodiment 1-5

[0056]

[0057]

Embodiment 6

[0058] Embodiment 6: A bamboo charcoal memory cotton, the difference from Example 1 is that the bamboo charcoal fiber is loaded with nano-titanium dioxide, and the weight ratio of modified nano-titanium dioxide to bamboo charcoal fiber is 1:10.

[0059] The method that bamboo charcoal fiber loads nano-titanium dioxide comprises the following steps:

[0060] (1) adding nano-titanium dioxide and sodium silicate to distilled water, stirring evenly, and obtaining a suspension after ultrasonic vibration;

[0061] (2) bamboo charcoal fiber is put into suspension, soaks, and nano-titanium dioxide enters inside bamboo charcoal fiber, takes out bamboo charcoal fiber, cools to normal temperature after drying;

[0062] (3) Put the cooled bamboo charcoal fiber into the suspension again for soaking, take it out and dry it, cool it, repeat the steps of soaking, drying and cooling several times, and obtain the bamboo charcoal fiber loaded with nano-titanium dioxide.

[0063] Wherein, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com