Silicon carbide PiN diode with buried layer structure

A silicon carbide and diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing diode on-resistance, small forward current, reducing on-state loss, etc., to improve forward on-current and enhance the effect. , Improve the effect of forward conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The advantages of the silicon carbide PiN diode with buried layer structure of the present invention will be further described by way of examples, simulation and description of drawings.

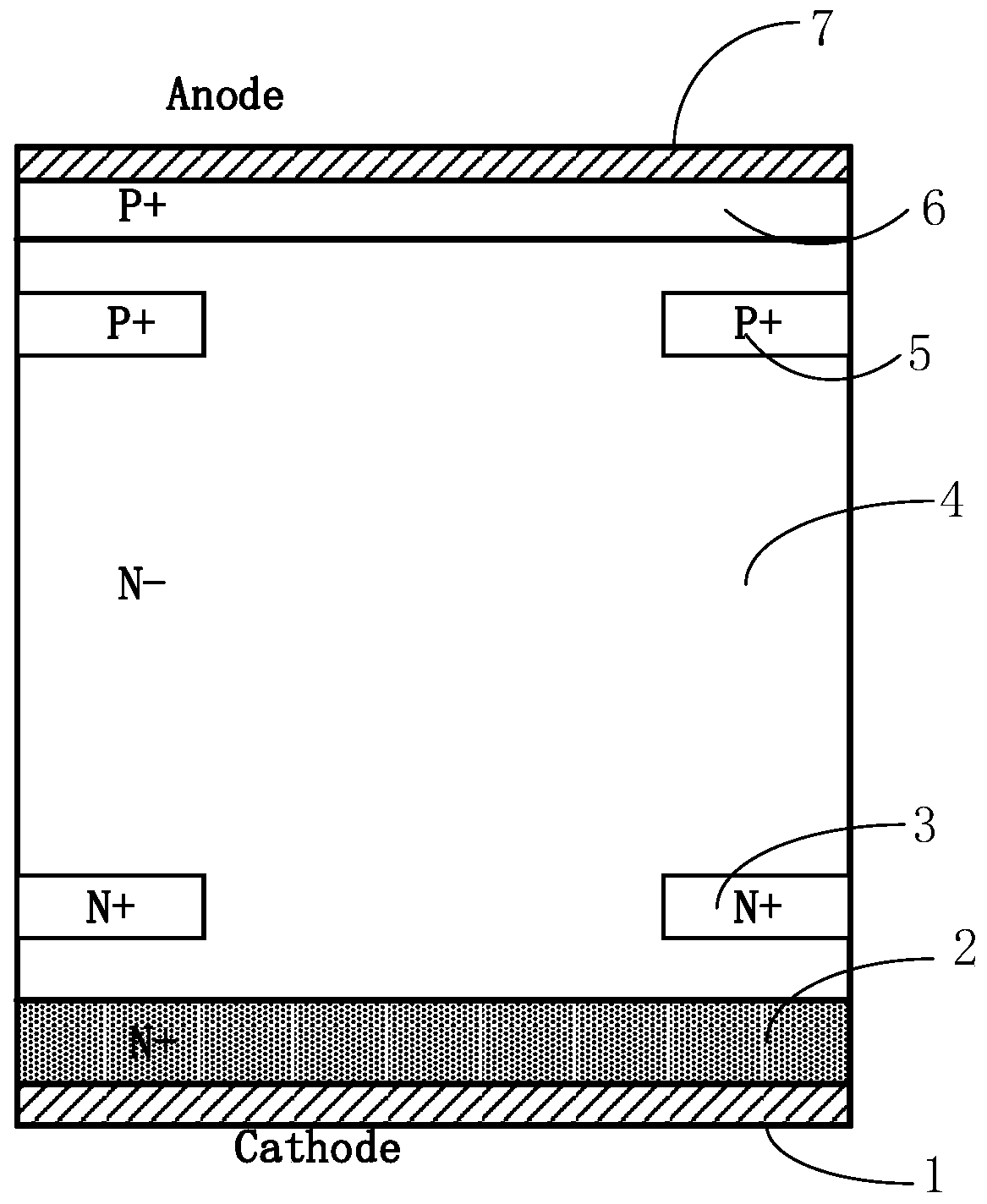

[0017] Such as figure 1 As shown, a silicon carbide PiN diode with a buried layer structure proposed by the present invention includes an N-type silicon carbide substrate 2, a cathode 1 is connected to the lower end of the N-type silicon carbide substrate 2, and a cathode 1 is connected to the upper end of the N-type silicon carbide substrate 2. The N-type silicon carbide epitaxial layer 4, the upper surface of the N-type silicon carbide epitaxial layer 4 is provided with a P-type region 6, and a metal anode 7 is connected above the P-type region 6, and the P-type region 6 forms an ohmic contact with the metal anode 7.

[0018] The present invention proposes to set only N-type buried layer 3 in N-type silicon carbide epitaxial layer 4, or only set P-type buried layer 5 in N-type silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com