Pressure-sensitive adhesive for high-function self-adhesive film of refrigerator door and preparation method thereof

A refrigerator door, high-function technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as poor performance, improve viscosity, improve stability, increase low temperature The effect of anti-freeze ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

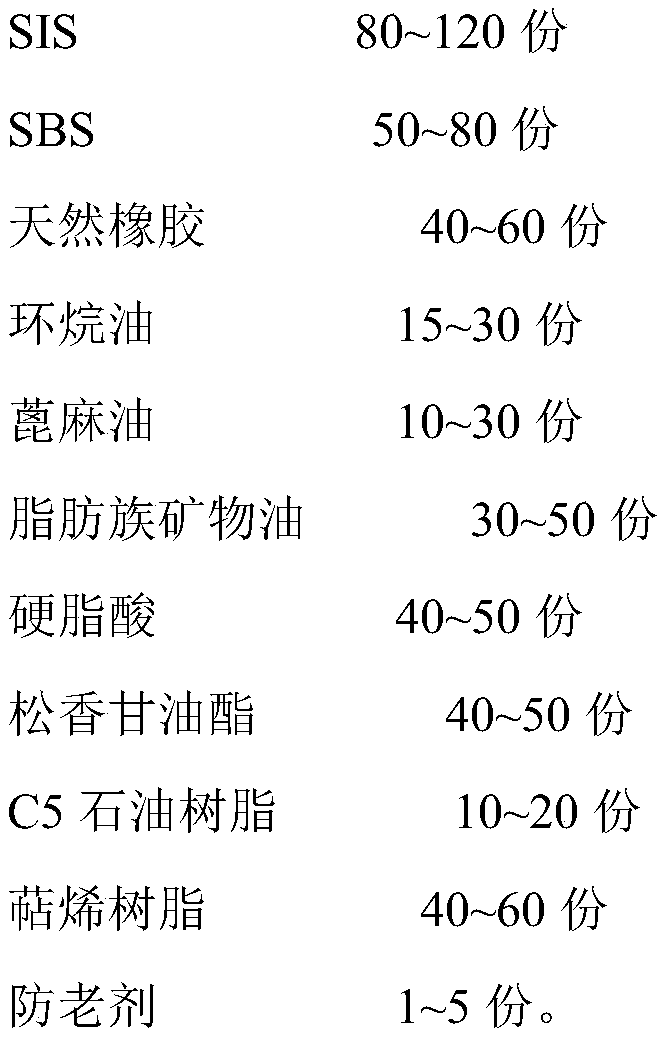

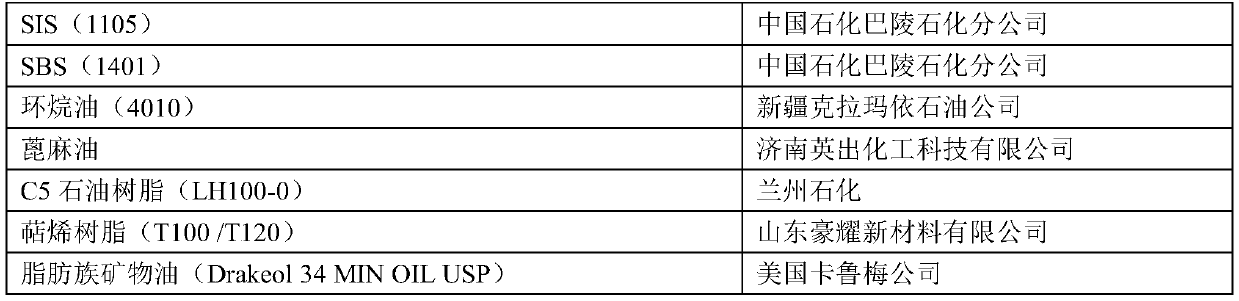

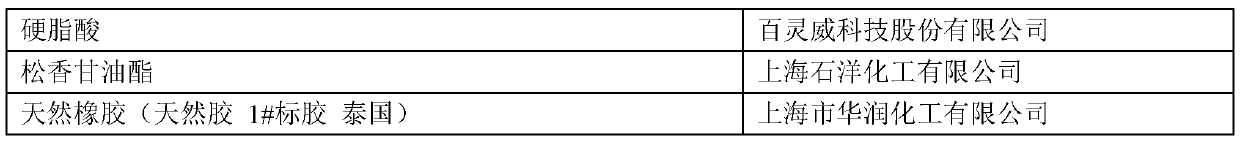

[0038] A pressure-sensitive adhesive for label paper of high-performance self-adhesive film for refrigerator doors,

[0039] Prepared by reacting the components in the following amounts:

[0040] 80kg SIS, 50kg SBS, 45kg natural rubber, 15kg naphthenic oil, 15kg castor oil, 35kg aliphatic mineral oil, 42.5kg stearic acid, 42.5kg rosin glyceride, 12kg C5 petroleum resin, 45kg terpene resin, 2kg anti-aging agent.

[0041] Wherein, the terpene resin is a mixture of T-100 and T-120 terpene resin in a ratio of 1:1 by weight; the anti-aging agent is selected from any one of styrenated phenol, antioxidant 1010 or antioxidant 264. Yes, the antioxidant 1010 is selected in this embodiment.

[0042] Concrete preparation method comprises the following steps:

[0043] Step 1. Grind the rosin glyceride weighed according to the above ratio and add it to the stirring reactor, then add the same amount of stearic acid, heat up to 240°C, and keep the temperature for reaction for 4 hours;

[...

Embodiment 2~6

[0047] Examples 2-6 all relate to a pressure-sensitive adhesive used for the label paper of the high-function self-adhesive film of the refrigerator door. The dosage of each component in Examples 2-6 is specifically shown in Table 2.

[0048] Table 2. Embodiment 2~6 group distribution table

[0049]

[0050]

Embodiment 2-6

[0051] The concrete preparation method of embodiment 2-6 comprises the following steps:

[0052] Step 1. Grind the rosin glyceride weighed according to the ratio in Table 2 and add it to the stirring reactor, then add the same amount of stearic acid, heat up to 240°C, and keep the temperature for 4 hours;

[0053] Step 2. After cooling the reactor to 150°C, add naphthenic oil, castor oil, C5 petroleum resin, terpene resin, and pass N 2Protection, heat up to 200°C under stirring conditions, so that the added materials are in a molten state;

[0054] Step 3, continue to add SIS, SBS and natural rubber, stir for 2 hours, stop heating, and obtain a high-function self-adhesive pressure-sensitive adhesive for refrigerator doors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com